Transparent polypropylene with high fluidity and high heat resistance and preparation method thereof

A transparent polypropylene, high heat-resistant technology, applied in the field of modified plastics, can solve the gaps in transparency, mechanical properties, heat resistance, restrictions on the promotion and use of transparent polypropylene materials, rigidity, insufficient heat resistance, etc., to achieve improved Transparency, broaden the scope of use, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

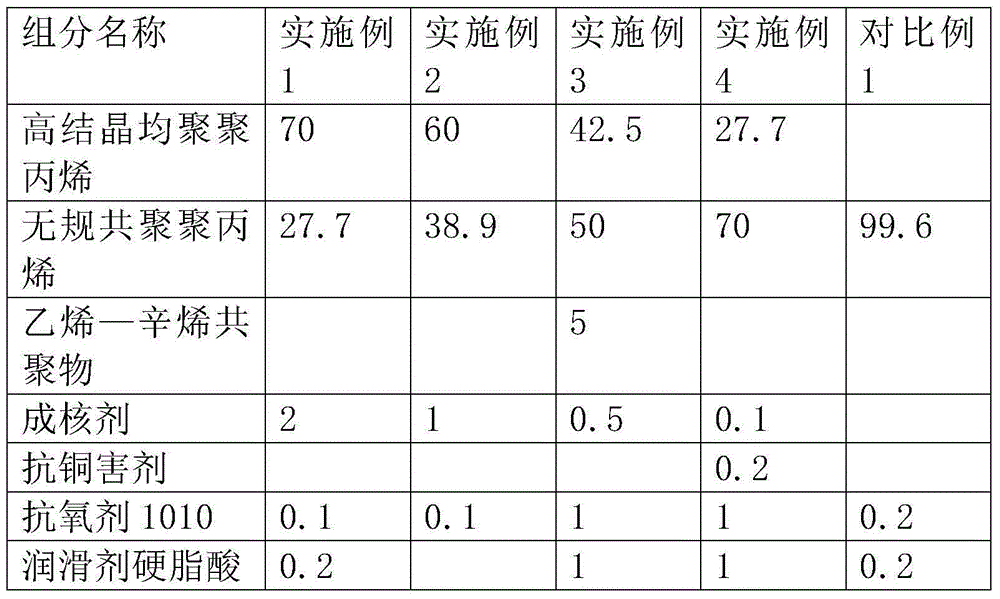

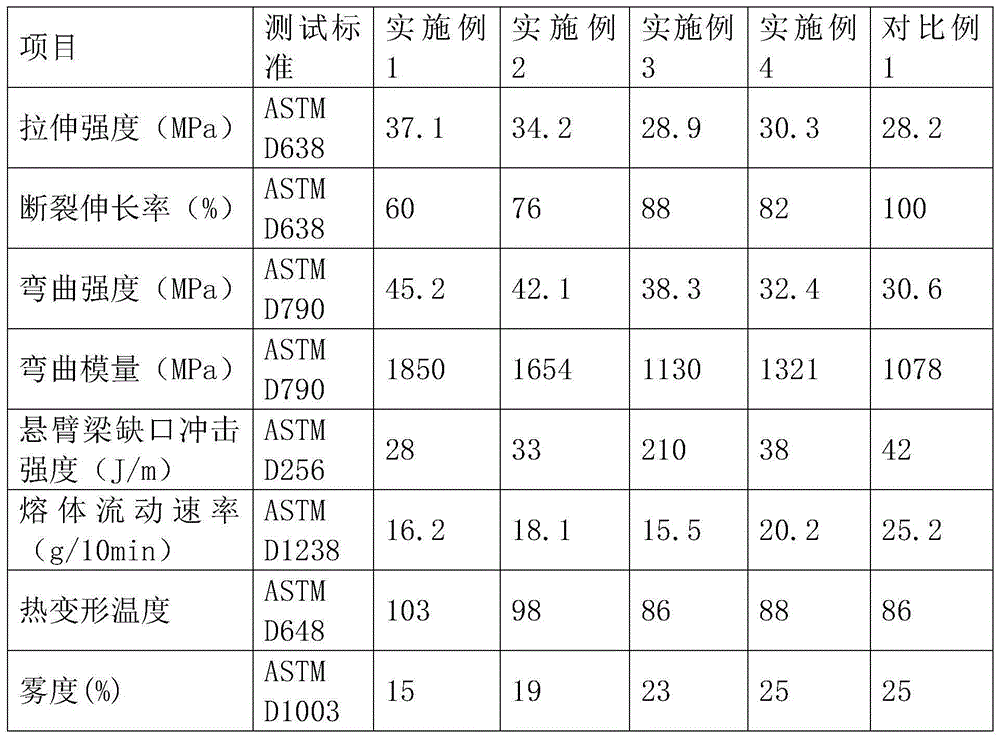

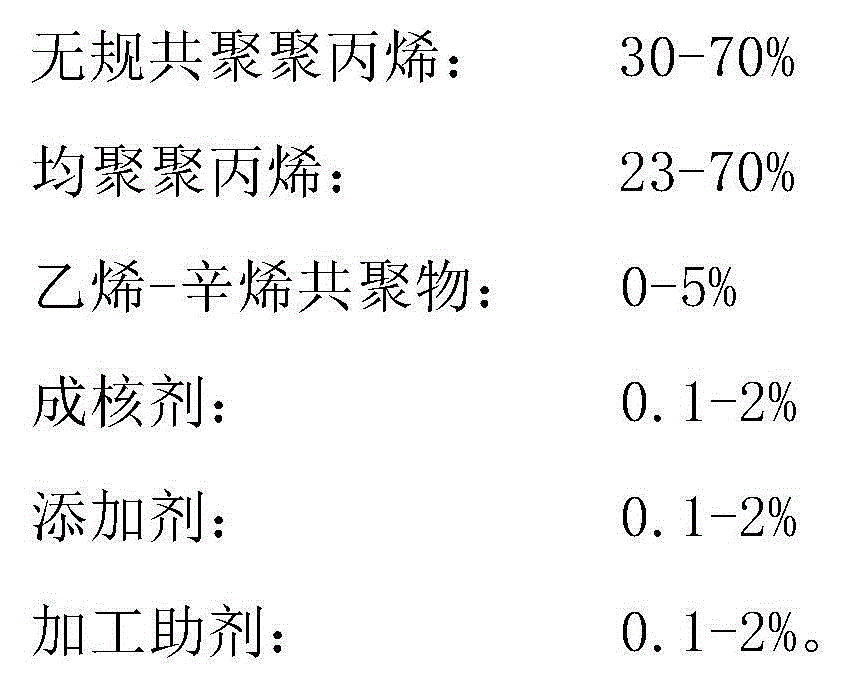

[0020] A high flow, high rigidity, high heat-resistant transparent polypropylene composite material, the proportioning ratio of its components is as shown in table 1, and the nucleating agent is selected from sorbitol, and its preparation method comprises the following steps:

[0021] Weigh each component according to the above weight percentage, mix each component evenly and feed it from the main feeding port of the extruder, and each component is melted, extruded, and granulated in the extruder for 3-10 minutes to obtain High-flow, high-rigidity, high-heat-resistant transparent polypropylene composite material product, the granules prepared according to the ratio of each embodiment were injection molded into mechanical specimens for testing, and the test results are shown in Table 2.

[0022] In Table 1, the flexural modulus of high crystalline homopolypropylene is >1500MPa; the melt flow rate of propylene-ethylene random copolymer polypropylene is 25g / min when the load is 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com