Low-temperature reversible thermochromic material and preparation method and application thereof

A thermochromic material, a low-temperature solvothermal technology, which is applied in the fields of color-changing fluorescent materials, chemical instruments and methods, and color/spectral property measurement, etc. and other problems, to achieve the effect of bright color, sharp color change, and short recolor time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

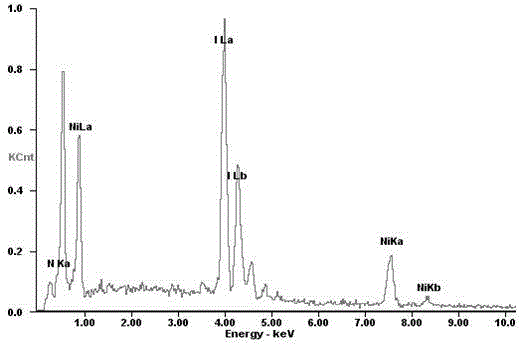

[0025] The preparation method of the low-temperature reversible thermochromic material is as follows: a low-temperature solvothermal method is used to prepare the thermochromic material. In terms of molar ratio, nickel powder: iodine simple substance=1.0-2.0:0.8-1.5, ammonia water 3.0-6.0 mL is used as the reactant, Put it into a 25 mL reactor and place it at 120-180°C for 4-7 days to react, and wash it with distilled water and ethanol respectively to obtain a low-temperature reversible thermochromic material.

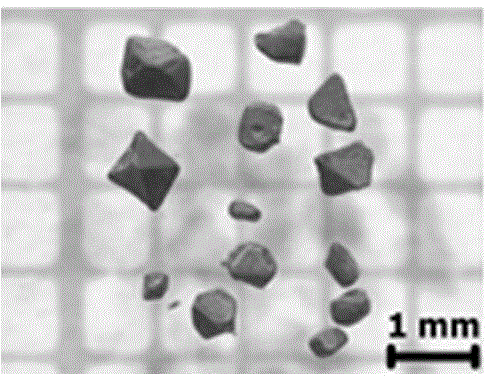

[0026] The color change principle of the low-temperature reversible thermochromic material is the gain and loss of crystal water, which can be used to detect water.

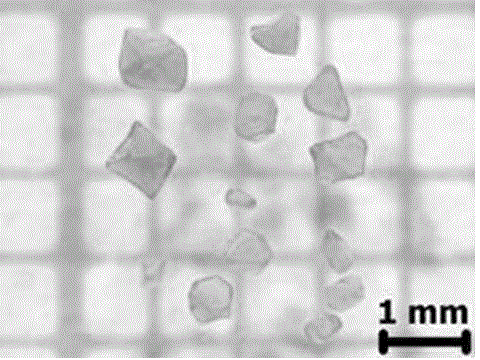

[0027] The prepared low-temperature reversible thermochromic material is tested for composition formula determination, color-changing temperature range, color, recolor time, color-changing sensitivity, heat resistance and other comprehensive color-changing performance tests; the low-temperature reversible ...

Embodiment 1

[0030] Weigh Ni 1.0 mmol (0.059 g), I 2 0.8 mmol (0.203 g), measure NH 3 ·H 2 O 3.0 mL, put it into a 25 mL reactor, and turn it over at 120 °C for 7 days and then cool naturally. The product was washed several times with distilled water and ethanol respectively to prepare a low-temperature reversible thermochromic material.

Embodiment 2

[0032] Add Ni 1.5 mmol (0.089 g), I 2 1.2 mmol (0.305 g) and NH 3 ·H 2 The consumption of O 5.0 mL, raising temperature to 150 ℃, shortening reaction time is 5 days, all the other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com