Super virgin camellia oil and preparation method thereof

A special-grade camellia oil technology, which is applied in the fields of fat oil/fat refining, edible oil/fat, fat oil/fat production, etc., can solve the problem of not disclosing the crystallization of saturated fat with high melting point, the control of cooling process is not specific enough, and the loss of nutritional components of camellia oil and other problems, to achieve the effect of enhancing appetite, clear products, and zero trans fatty acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

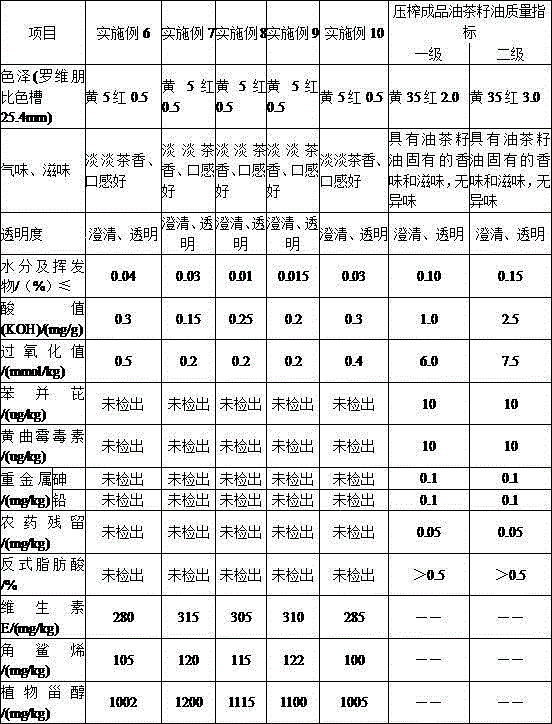

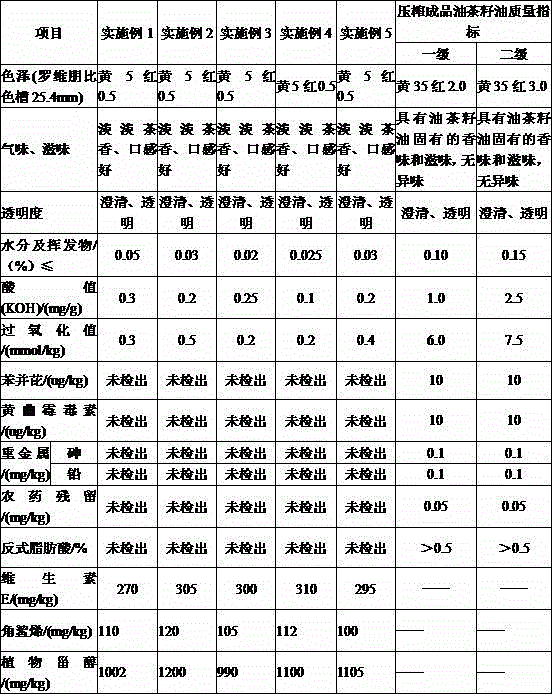

Examples

Embodiment 1

[0040] The following method is used to prepare a kind of tea oil:

[0041] A. Make the raw material of the special -grade virgin tea oil: Take fresh tea seeds and open it naturally; control the water at 8 quality%; remove all the seed shells of the oral tea seeds to get the oral tea seed kernels;

[0042] B. Virgin: Squeeze the categorine seeds obtained by the step A, and squeeze the seed temperature of the oil. The seed temperature is the environmental temperature, that is, the temperature, and the temperature of the squeezing and the oil of the squeezing oil is lower than 60 ° C.Tea withered;

[0043] C. Frozen removal: Put the virgin tea oil into the freezer tank, and freeze and cool down according to the following three stages.The first stage: first cool down at a speed of 2.0 ° C / hour to 20 ° C, maintain 15 hours, and the mixing speed is 50 R / min; then the speed of 2.0 ° C / hour is cooled to 10 ° C, maintained for 5 hours, the mixing speed is 50 to 50R / min; In the second stage...

Embodiment 2

[0047] Adopting the basic method as the embodiment 1, a special -grade virgin tea oil is prepared. The difference is that before the program in the step C is frozen and cools down, the rough product of the virgin mountain tea oil is added, and the tea obtained from the step B is added to the tea obtained from the step b dry.The 60 -mesh -meter fine powder is grinded. The amount of tea withered powder is 2: 100 with the quality ratio of the rough products of the virgin mountain tea. It acts as a crystal nucleus during the frozen crystallization process to improve the purification effect of refrigeration crystal.

Embodiment 3

[0049] Adopting the basic method as Example 1, a special -grade virgin tea oil is prepared. The difference is that before the program in the step C is frozen and cooling, the rough products of the virgin mountain tea oil are added to the rough products of the virgin mountain.The 200 meter -made powder, the amount of tea dry powder is 0.05: 100 with the quality ratio of the rough tea oil products of the virgin mountain. In the process of frozen crystal, it acts as a crystal nucleus to improve the purification effect of refrigeration and crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com