Low-temperature purification of fragrant camellia oil and preparation method thereof

A technology of camellia oil and strong fragrance, which is applied in the direction of fat oil/fat refining, edible oil/fat, fat production, etc., to achieve the effect of low process conditions and simple method flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

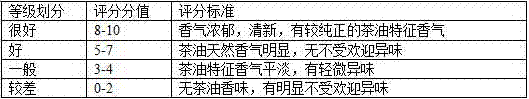

Examples

Embodiment 1

[0033] Adopt the following method to prepare a kind of low-temperature purification Luzhou-fragrant camellia oil:

[0034] (1) Put the camellia oil obtained after pressing fresh tea seeds into the purification tank;

[0035] (2) filtering the camellia oil obtained after the fresh camellia seed is first pressed, blowing dry with compressed nitrogen, smashing, and obtaining the filter residue;

[0036](3) Put the virgin camellia oil into the purification tank, add the filter residue, the weight ratio of filter residue to camellia oil is 2:100, adjust the stirring speed to 60 r / min, and stir evenly. The first stage: use 3°C / min The speed is gradually raised to 65°C, the purpose is to completely break the possible crystals of the camellia oil first, to prevent subsequent cooling and early crystallization, which will affect the speed of impurity removal, harm removal and filtration; the second stage: start the water cycle and freezer, at 0.5°C / The temperature is gradually lowered...

Embodiment 2

[0039] Adopt the following method to prepare a kind of low-temperature purification Luzhou-fragrant camellia oil:

[0040] (1) Put the camellia oil obtained after pressing fresh tea seeds into the purification tank;

[0041] (2) filtering the camellia oil obtained after the fresh camellia seed is first pressed, blowing dry with compressed nitrogen, smashing, and obtaining the filter residue;

[0042] (3) Put the virgin camellia oil into a purification tank, add filter residue, the weight ratio of filter residue to camellia oil is 10:100, adjust the stirring speed to 55 r / min, stir evenly, the first stage: use 5°C / min The speed is gradually raised to 65°C, the purpose is to completely break the possible crystals of camellia oil first, to prevent subsequent cooling and early crystallization, which will affect the speed of impurity removal, pest removal and filtration; the second stage: start the water cycle and freezer, at 0.8°C Gradually cool down to 20°C at a speed of 0.3°C / m...

Embodiment 3-7

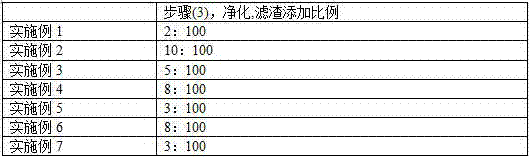

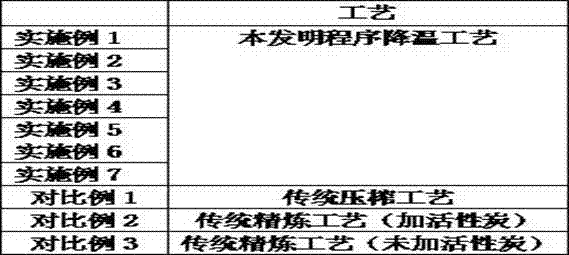

[0045] The same method as in Example 1 was used to prepare Example 3-7 low-temperature purification of Luzhou-fragrant camellia oil. The difference is the addition ratio of the filter residue in the purification process of step (3). Other conditions are the same, as shown in Table 1. .

[0046] Table 1 The main parameters of the manufacturing process steps

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com