Method for testing content of N-methyl pyrrolidone in liquid crystal

A technology of methylpyrrolidone and its determination method, which is applied in the field of organic matter analysis, can solve problems such as uncontrollable polymerization, poor alignment of liquid crystals, and failure to find test methods, etc., and achieve the effect of reducing the risk of process abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

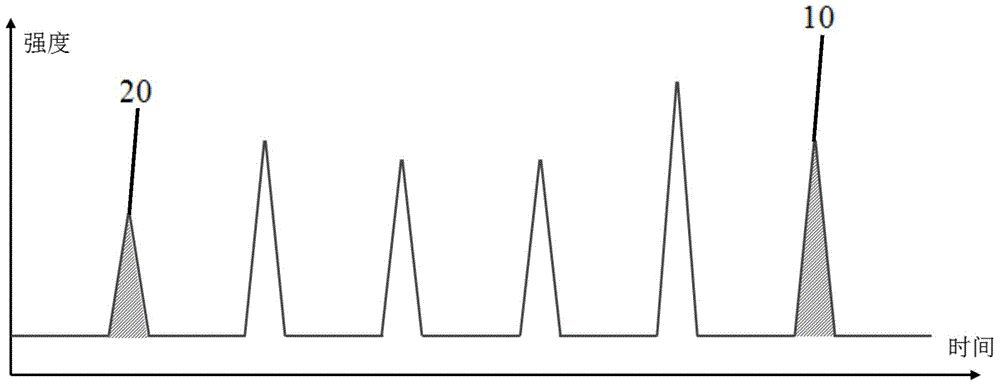

[0035] First prepare the standard sample solution, and establish the working curve according to the chromatographic peaks of each component measured by the standard sample solution. Specifically refer to the following steps:

[0036] (1) Take N-methylpyrrolidone (hereinafter referred to as NMP) with a mass of 0.15242g and A-type liquid crystal with a mass of 9.05692g on an electronic balance, use the A-type liquid crystal as a solvent, and NMP as a solute to obtain a concentration of 16.551g / kg of standard mother liquor.

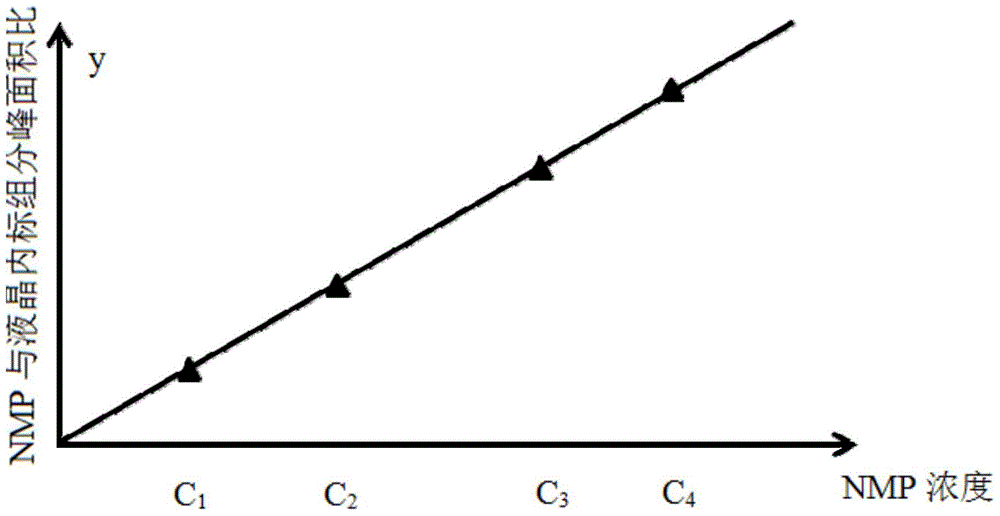

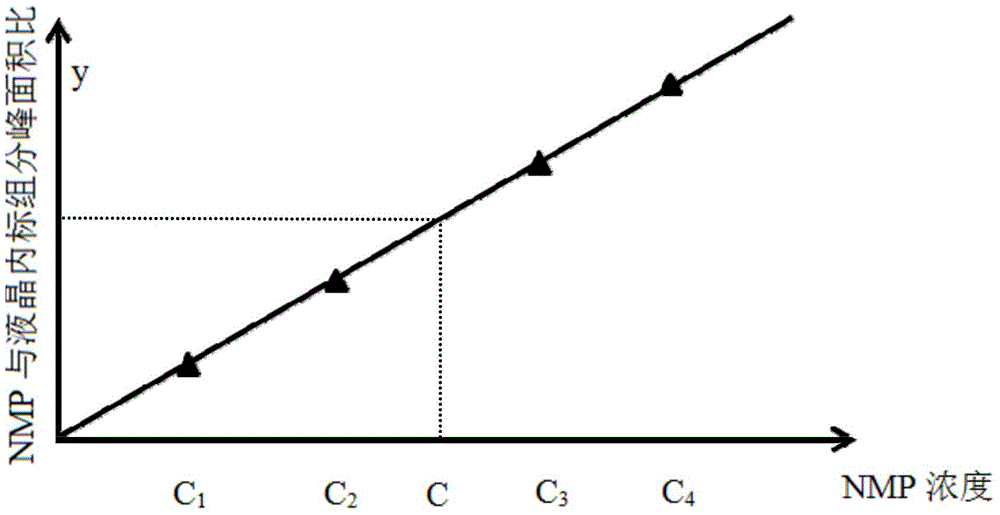

[0037] With above-mentioned A-type liquid crystal as solvent, the standard mother liquor that obtains concentration is 16.551g / kg is carried out step by step dilution, obtains the standard solution of four groups of known concentrations (concentration is respectively 0.1741g / kg, 0.3515g / kg, 0.7849g / kg and 1.5945g / kg); It should be noted that in the process of dilution, it should be ensured that the concentration range of the four groups of standard soluti...

Embodiment 2

[0058] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 2 and embodiment 1 is that the content of NMP in the B type liquid crystal in another liquid crystal panel is tested with the method in embodiment 1, 4 groups of parallel experiments, the chromatographic peak of NMP is the same as that of the same group The area ratio of the internal standard component peaks of the standard solution is shown in Table 4.

[0059] Table 4

[0060] test group

[0061] Through linear fitting, obtain the working curve equation of the present embodiment to be y=9.3547x-0.1264, wherein R 2 = 1, such as Figure 6 shown.

[0062] Calculate the NMP content in the B-type liquid crystal sample, conduct 6 parallel experiments, and the test results are shown in Table 5.

[0063] table 5

[0064]

[0065] The same method as in Example 1 was a...

Embodiment 3

[0070] In the description of Embodiment 3, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 3 and embodiment 1 is that the content of NMP in the C type liquid crystal in another liquid crystal panel is tested with the method in embodiment 1, and the chromatographic peak of NMP is identical with the internal standard of the same group of standard solutions The area ratio of the component peaks, 4 groups of parallel experiments, as shown in Table 7.

[0071] Table 7

[0072]

[0073] Through linear fitting, obtain the working curve equation of the present embodiment to be y=5.4973x-0.0811, wherein, R 2 =0.9994, such as Figure 7 shown.

[0074] Calculate the NMP content in the C-type liquid crystal sample, and conduct 6 parallel experiments. The test results are shown in Table 8.

[0075] Table 8

[0076]

[0077] The same method as in Example 1 was used to car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com