Cooling and purifying environment protection system for industrial waste gas emissions

A technology of dust purification and airflow, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agents, etc., can solve problems such as external environmental pollution, achieve low operating costs, small volume, and save processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0015] Hot raw flue gas means untreated high-temperature exhaust gas containing a large amount of dust particles, gaseous pollutants and other impurities discharged from production workshops such as furnaces, ash workshops and coating production lines.

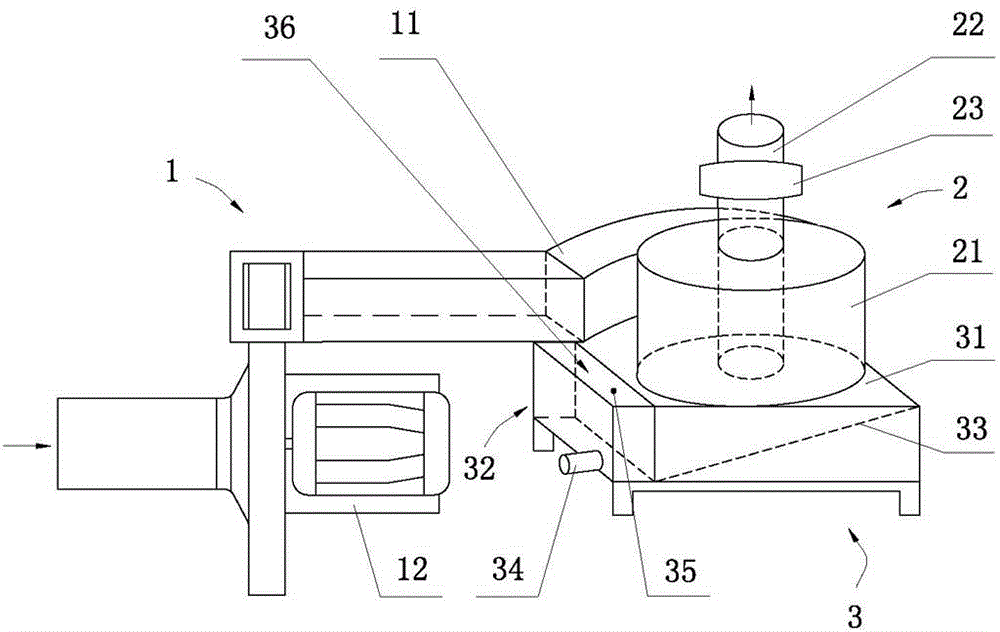

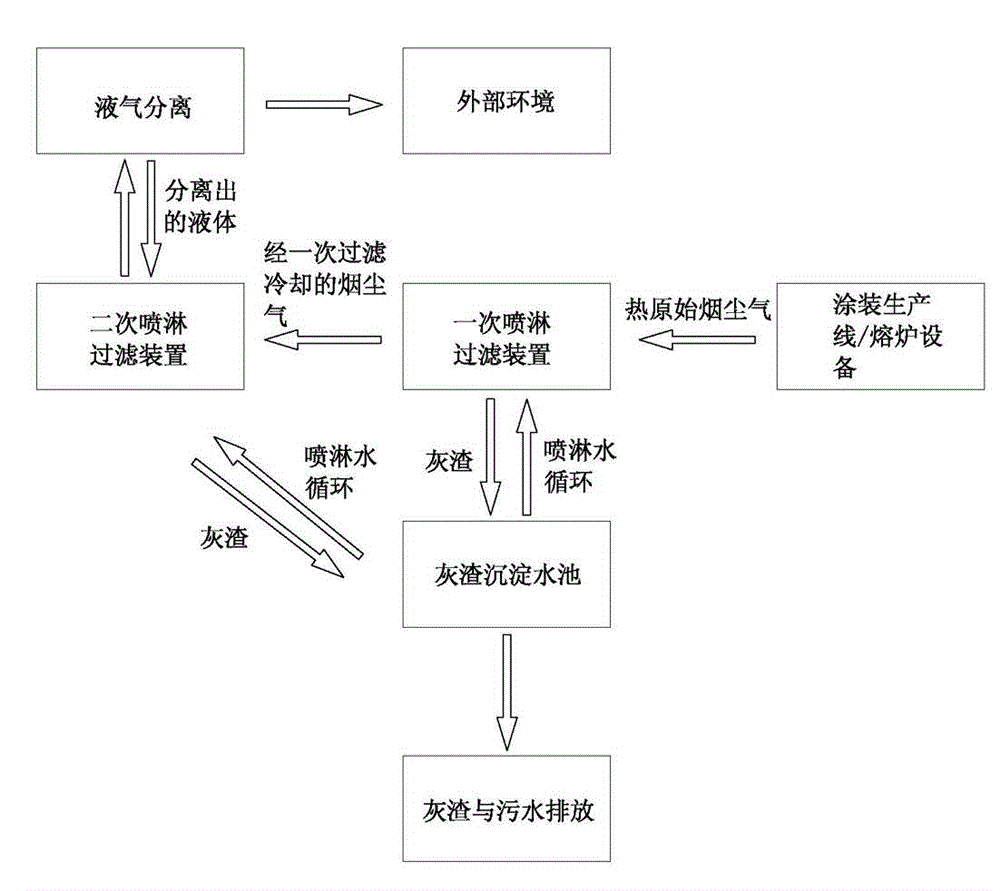

[0016] see figure 1 A soot purification mechanism provided in this embodiment includes: a) an air intake assembly 1; b) a sewage discharge device 3; and c) a soot gas cooling and purification device 2, including a primary spray filter 21 provided with an accommodation space, a device In the secondary spray filter 22 in the accommodation space, the primary air intake filter space for filtering and cooling the hot raw smok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com