Harmless treatment device for industrial solid waste

A solid waste, harmless treatment technology, applied in gas treatment, combined devices, incinerators, etc., can solve the problems of low resource utilization, many treatment processes, poor purification effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

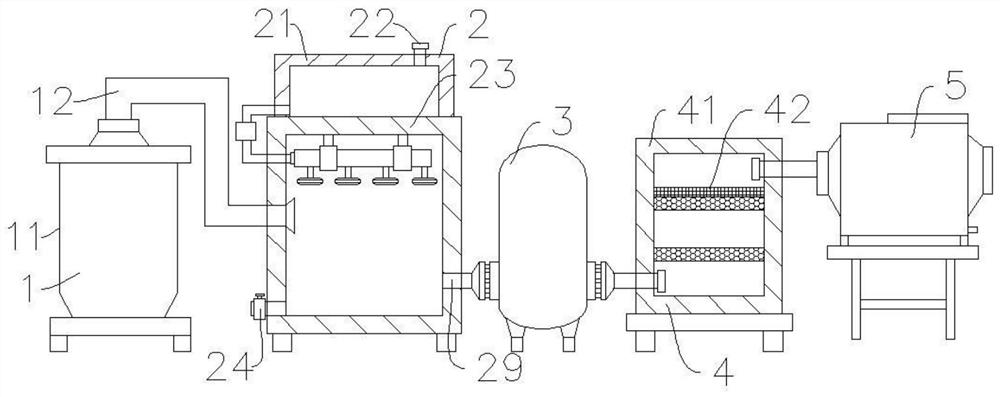

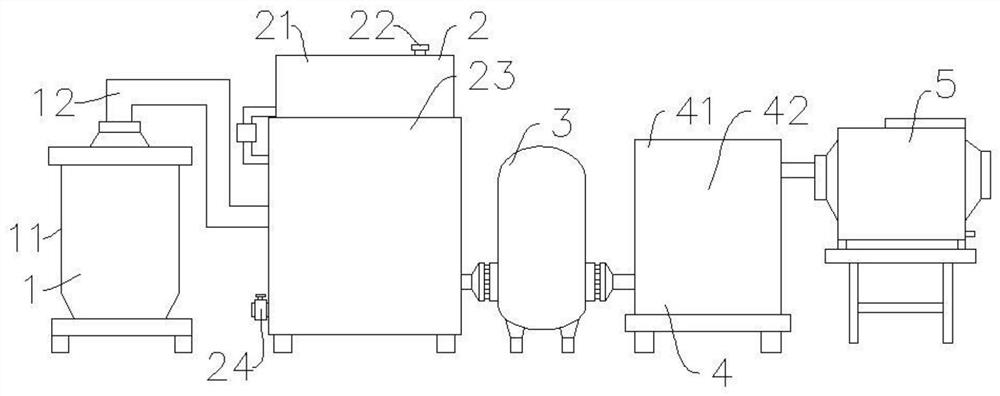

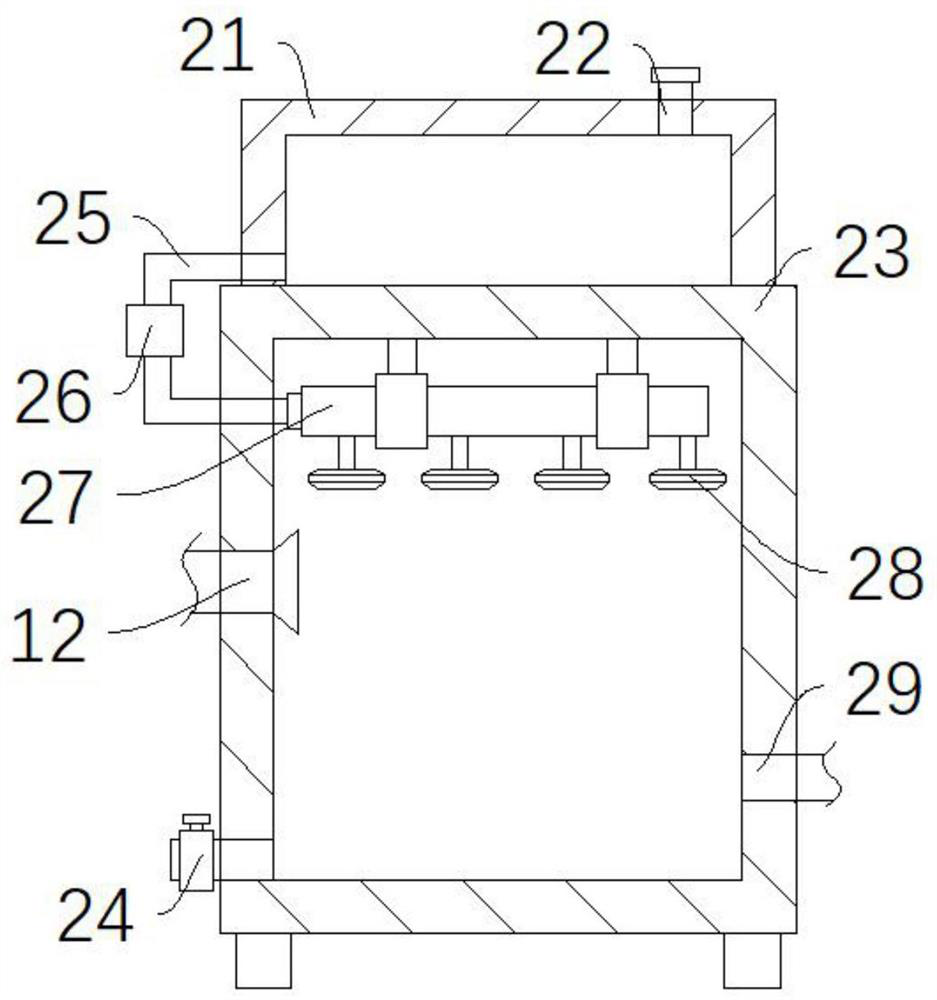

[0032] Such as Figure 1-Figure 8As shown, a harmless treatment device for industrial solid waste of the present invention includes a combustion mechanism 1 for burning solid waste, a heat exchanger 3, and a dust collector 5. One side of the mechanism 1 is used to cool down the flue gas from the quenching mechanism 2 to prevent it from causing damage to the activated carbon components in the filter mechanism 4, and the dust collector 5 is arranged on the side of the heat exchanger 3 away from the combustion mechanism 1 , used to absorb the fly ash in the flue gas, and also includes a quenching mechanism 2 and a filtering mechanism 4 for quenching the flue gas to suppress the formation of dioxins, the quenching mechanism 2 is connected between the combustion mechanism 1 and the heat exchanger 3, The filter mechanism 4 is connected between the heat exchanger 3 and the dust remover 5. The filter mechanism 4 includes a filter box 41, a filter screen 42, a second activated carbon p...

Embodiment 2

[0038] Such as Figure 4 , Figure 5 As shown, the difference between embodiment 2 and embodiment 1 is that the lye storage tank 21, liquid inlet pipe 22, quench tank 23, drain pipe 24, infusion pipe 25, the first water pump 26, liquid collection Pipe 27, atomizing nozzle 28, and second air delivery pipe 29 are replaced with quenching box 23, liquid discharge pipe 24, second air delivery pipe 29, motor 201, rotating shaft 202, stirring rod 203, and the smoke generated by combustion passes through the first air delivery pipe 12 is discharged into the quenching box 23, and the gas outlet of the first gas delivery pipe 12 is submerged in the lye. At this time, the starter motor 201 drives the rotating shaft 202 and the stirring rod 203 to rotate and stir the lye, so that the flue gas is fully mixed in the lye. To make the acid gas react more thoroughly, the mixed flue gas is finally discharged into the heat exchanger 3 through the second gas delivery pipe 29 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com