Preparation method of graphene bonding modified silica fume

A graphene and modified silicon technology, applied in the field of cement concrete admixtures, can solve the problems of unstable concrete performance, complicated preparation process of modified graphene, low degree of dispersion, etc., achieve excellent dispersion retention, improve electrical properties, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

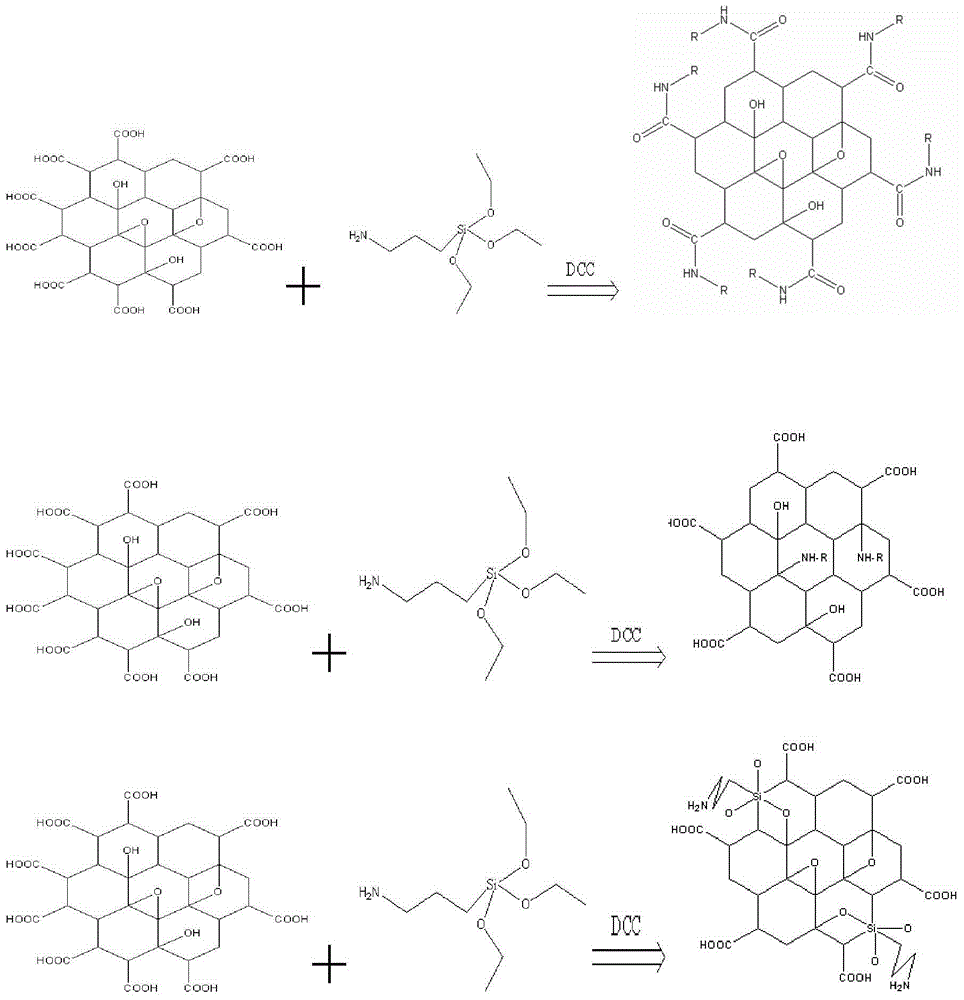

Method used

Image

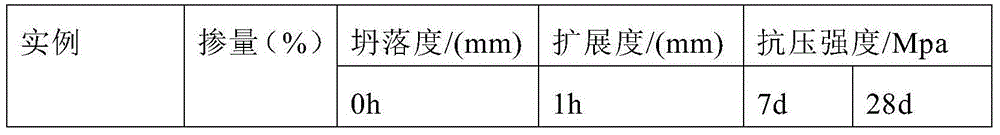

Examples

Embodiment 2

[0030] (1) Take 10ml of silane coupling agent KH550, 36ml of ethanol, and 4ml of water in a test tube to prepare a solution of silane coupling agent KH550 (20% of silane coupling agent KH550, 72% of ethanol, and 8% of water). Take 15ml of the solution and place it in a test tube, which is designated as test tube 1;

[0031] (2) Get 10mg carboxylated graphene and dicyclohexylcarbodiimide DCC respectively, add in the test tube 1 successively, and adjust its pH to be 6~8, ultrasonic dispersion 1h, obtain brown homogeneous mixed solution in the test tube 1, Then stir the homogeneous mixture, and heat it to 70° C., and keep the homogeneous mixture at this temperature for 24 hours to obtain a black uniform coupling-modified graphene mixture;

[0032] (3) Place the above-mentioned coupling-modified graphene mixed solution in a separator for separation for 1 hour. After separating the coupling-modified graphene sheet, rinse it repeatedly with pure alcohol until it is clean, then put i...

Embodiment 3

[0037] (1) Take 9ml of silane coupling agent KH550, 36ml of ethanol, and 5ml of water in a test tube to prepare a solution of silane coupling agent KH550 (18% of silane coupling agent KH550, 72% of ethanol, and 10% of water). Take 15ml of the solution and place it in a test tube, which is designated as test tube 3;

[0038] (2) Take 12mg of carboxylated graphene and 3mg of boride catalyst boric acid respectively, add them to test tube 3 in turn, and adjust its pH to 6-8, ultrasonically disperse for 1.5h, and obtain a brown uniform mixed solution in test tube 3, then stir The homogeneous mixed solution is heated to 75° C., and the homogeneous mixed solution is kept at this temperature for 28 hours to obtain a black uniform coupling-modified graphene mixed solution;

[0039] (3) Place the above-mentioned coupling-modified graphene mixed solution in a separator for separation for 1 hour. After separating the coupling-modified graphene sheet, rinse it repeatedly with pure alcohol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com