Method for preparing 2-ethyl anthraquinone through one-step reaction of ethylbenzene and phthalic anhydride under catalysis of alkali desilication modified Hbeta molecular sieve

A molecular sieve catalyzed ethylbenzene and alkali desiliconization modification technology, applied in chemical instruments and methods, organic compound preparation, quinone preparation, etc. The problem is to achieve the effect of realizing large-scale industrial production, the reaction process is simple and easy to operate, and the conversion rate of phthalic anhydride is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

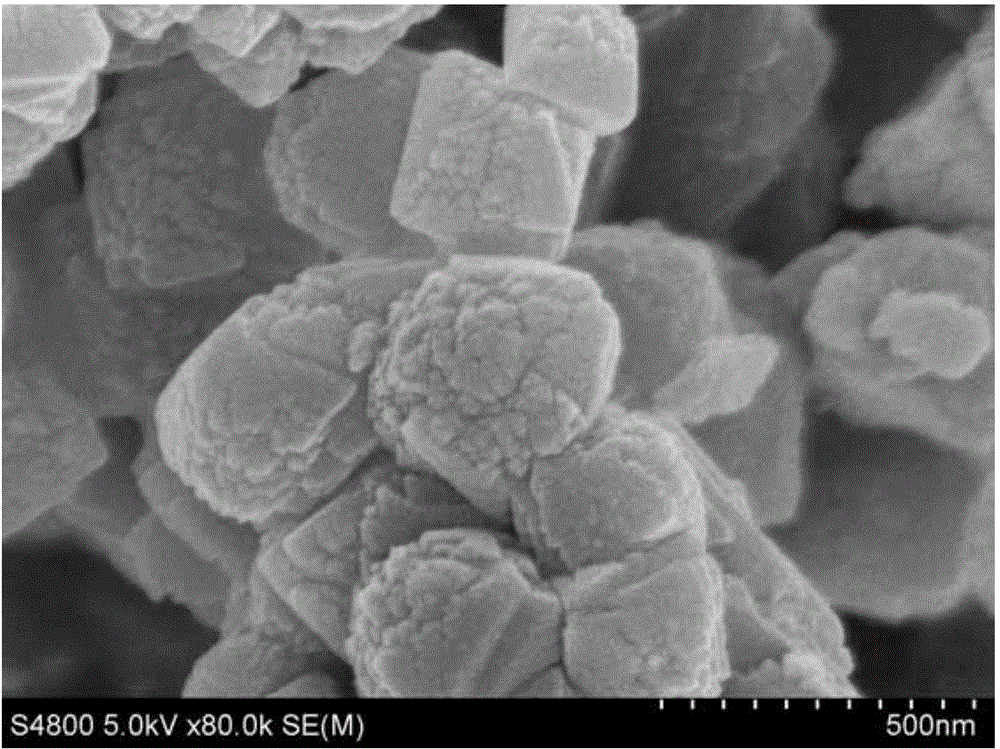

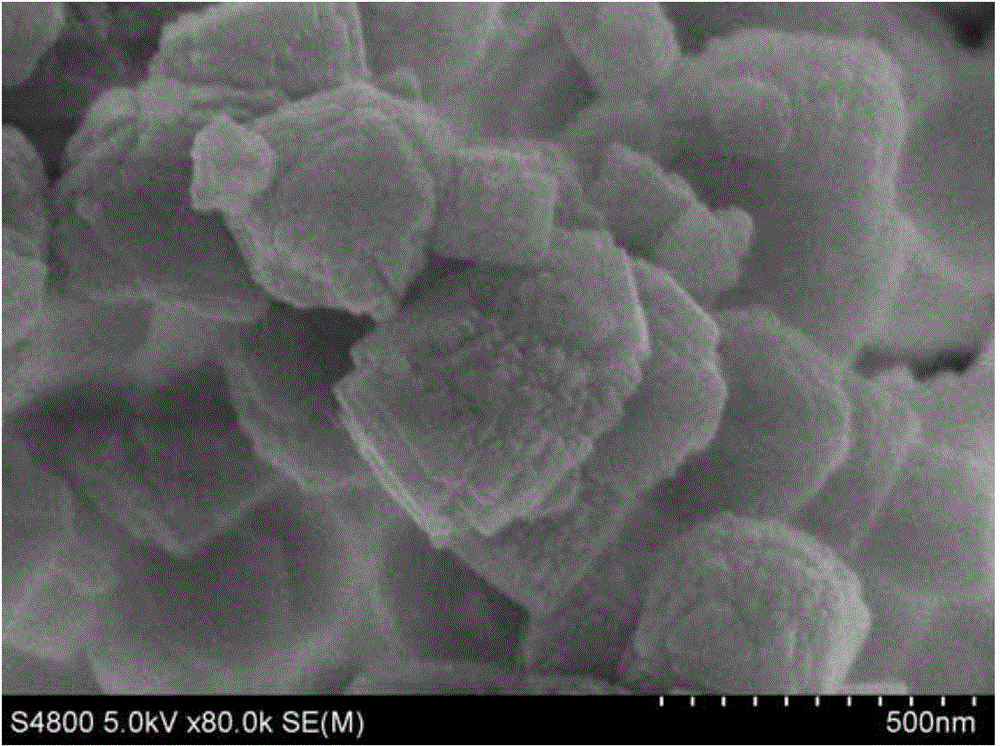

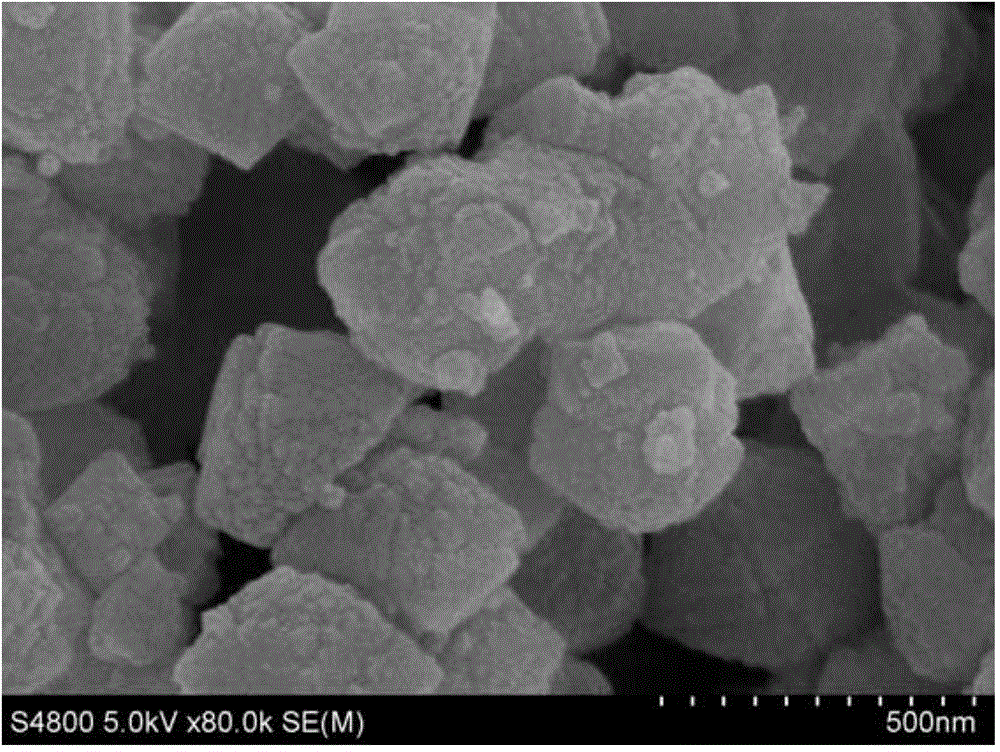

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: In this embodiment, a method for preparing 2-ethylanthraquinone by one-step reaction of ethylbenzene and phthalic anhydride catalyzed by Hβ molecular sieve modified by alkali desiliconization is carried out according to the following steps:

[0018] Add phthalic anhydride and ethylbenzene into the tank reactor, stir and mix evenly to obtain the reactant, then add the Hβ molecular sieve modified by catalyst alkali desiliconization into the tank reactor, and then react at a reaction temperature of 170°C to 230°C and React for 1.2h to 5h at a rotating speed of 400r / min to 800r / min to obtain a solid-liquid mixture. After cooling, separate the Hβ molecular sieve modified by alkali desiliconization of the solid catalyst to obtain 2-ethylanthraquinone;

[0019] The mass ratio of the phthalic anhydride to ethylbenzene is 1:(3-5); the mass ratio of the reactant to the Hβ molecular sieve modified by alkali desiliconization of the catalyst is 100:(8-20).

...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment is different from Embodiment 1 in that the mass ratio of phthalic anhydride to ethylbenzene is 1:3.5. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the alkali desilication modified Hβ molecular sieve is desiliconized by alkali under the condition of air atmosphere with an activation temperature of 400°C to 600°C. It is obtained by activating Hβ molecular sieve, and the activation time is 1h to 5h. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com