A kind of low-friction styrene-butadiene/natural rubber combined material and preparation method thereof

A technology of natural rubber and styrene-butadiene rubber, which is applied in the field of low-friction styrene-butadiene-butadiene/natural rubber materials and its preparation, can solve the problems of tetrafluoroethylene and graphite coating shedding, failure, etc., to improve service life and assembly production Efficiency, reduced friction coefficient, enhanced strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

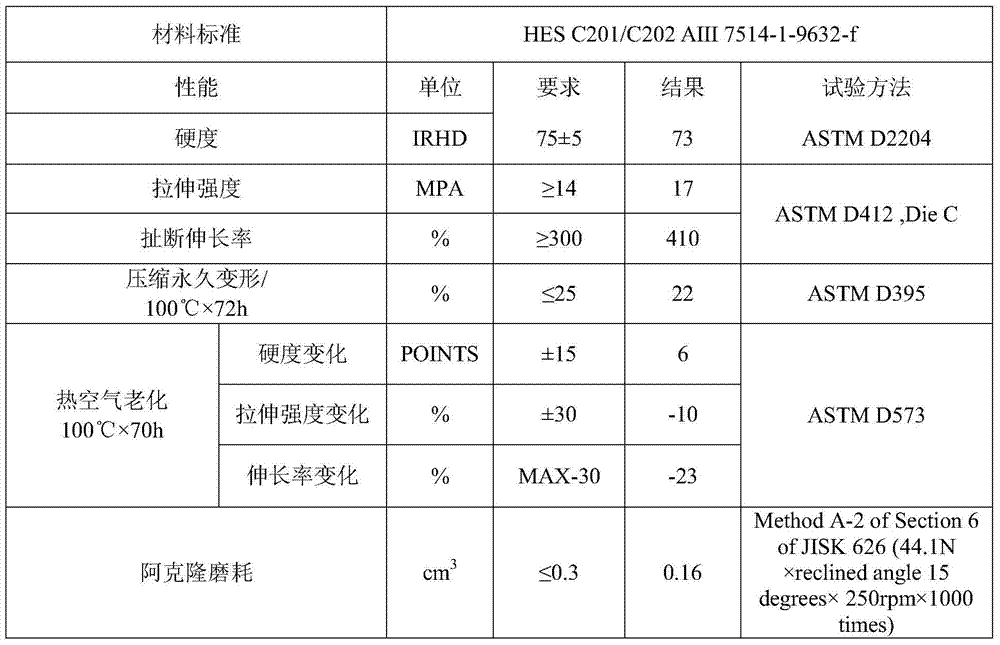

Examples

Embodiment 1

[0031] A low-friction styrene-butadiene / natural rubber composite material of this embodiment, its components and weight percentages are shown in Table 1.

[0032] Table 1 Components and weight percentages of a low-friction styrene-butadiene / natural rubber blend material in Example 1

[0033] Component name Weight percentage / % SBR 30 natural rubber 12 quick press carbon black 27 High wear-resistant carbon black 7 Zinc oxide 2.4 stearic acid 0.7 4,4'-Bis(phenylisopropyl)diphenylamine 0.4 Antiaging agent 4010NA 0.4 Accelerator CZ 0.4

[0034] Accelerator TT 0.2 sulfur 1.0 STRUKTOL TR 121 LUBRICANT 2.5 RF-50 physical peptization, lubricant 2.0 F1 graphite 7 Aromatic oil 7

[0035] The STRUKTOL TR 121 lubricant in this example is produced by the STRUKTOL company in the United States, and its main performance parameters are: melting point: 70-76 ° C; iodine value: ≤ 90 (...

Embodiment 2

[0048] The components and weight percentages of a low-friction styrene-butadiene-butadiene / natural rubber composite material in this embodiment are shown in Table 2.

[0049] Table 2 Components and weight percentages of a low-friction styrene-butadiene / natural rubber blend material in Example 2

[0050] SBR 32 natural rubber 10 quick press carbon black 25 High wear-resistant carbon black 8 Zinc oxide 2.0 stearic acid 0.8 4,4'-Bis(phenylisopropyl)diphenylamine 0.3 Antiaging agent 4010NA 0.4

[0051] Accelerator CZ 0.3 Accelerator TT 0.3 sulfur 0.8 STRUKTOL TR 121 LUBRICANT 3.5 RF-50 physical peptization, lubricant 1.6 F1 graphite 10 Aromatic oil 5

[0052] The source of each component in the above-mentioned table is with embodiment 1, adopts this component and its weight percent content, and its preparation method is as follows:

[0053] Step 1. Master batch mixing

[0...

Embodiment 3

[0061] A low-friction styrene-butadiene / natural rubber composite material of this embodiment, its components and weight percentages are shown in Table 3.

[0062] Table 3 Components and weight percentages of a low-friction styrene-butadiene / natural rubber blend material in Example 3

[0063] Component name Weight percentage / % SBR 27

[0064] natural rubber 15 quick press carbon black 27 High wear-resistant carbon black 5 Zinc oxide 3.0 stearic acid 0.6 4,4'-Bis(phenylisopropyl)diphenylamine 0.3 Antiaging agent 4010NA 0.3 Accelerator CZ 0.5 Accelerator TT 0.2 sulfur 1.0 STRUKTOL TR 121 LUBRICANT 1.8 RF-50 physical peptization, lubricant 2.3 F1 graphite 6 Aromatic oil 10

[0065] The source of each component in the above-mentioned table is with embodiment 1, adopts this component and its weight percent content, and its preparation method is as follows:

[0066] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com