Baijiu distilling device

A distillation device and liquor technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of reducing the liquor yield, food waste, and liquor damage, so as to improve the liquor yield and liquor speed, increase the liquor yield, and prevent alcohol damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

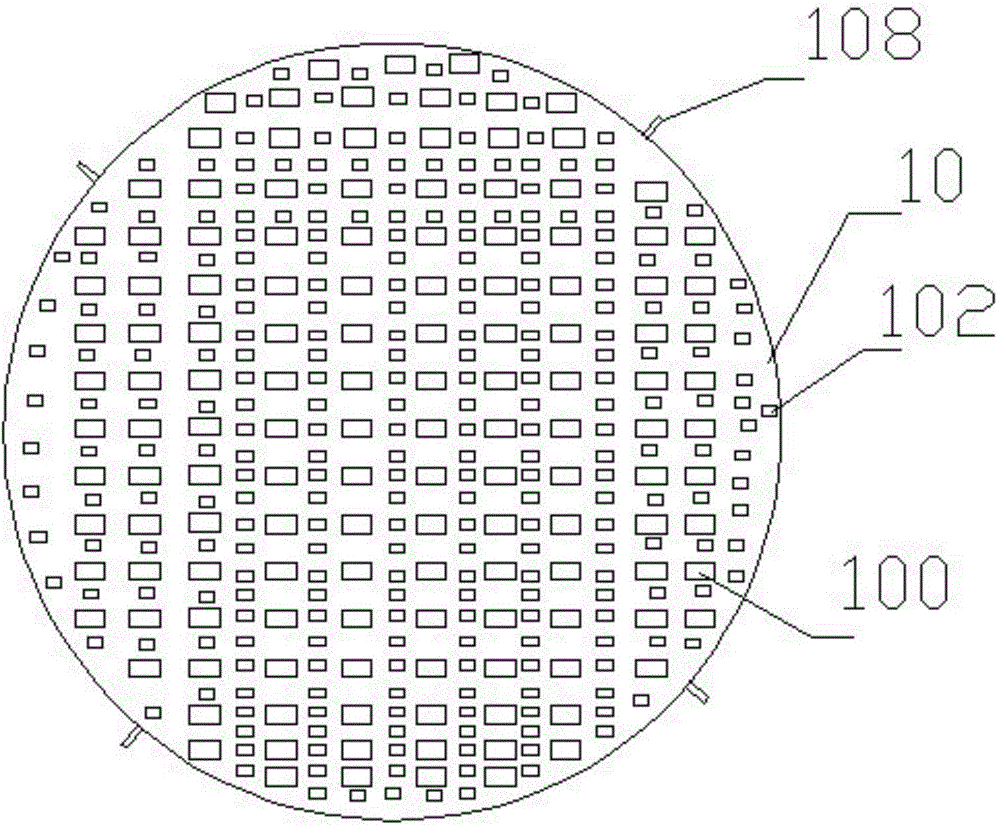

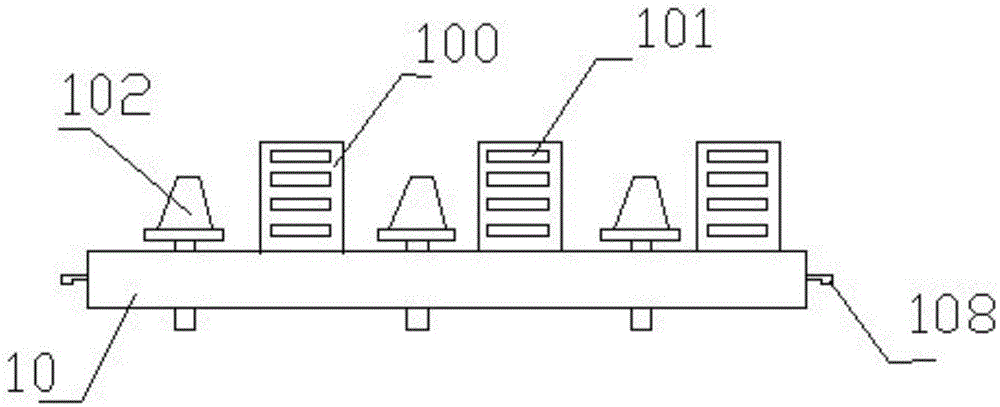

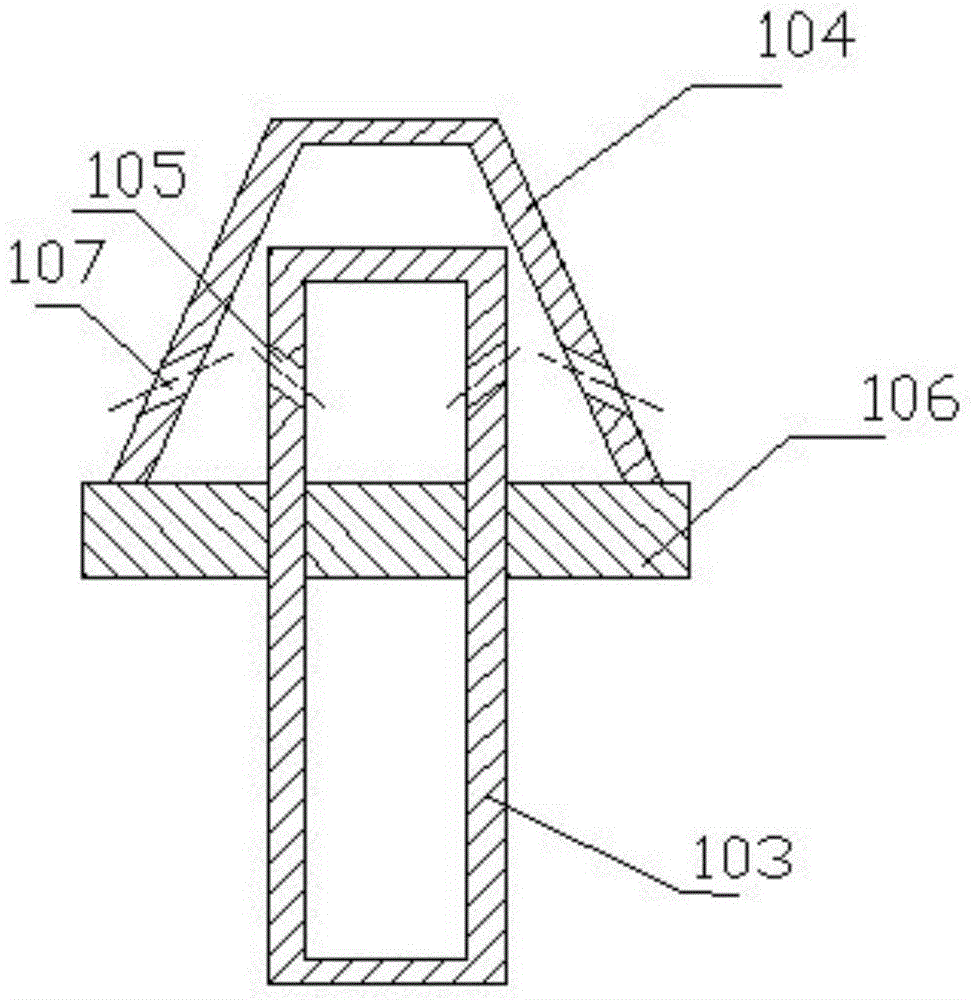

[0028] This embodiment includes a bottom pot 4, a retort grate 1, a barrel body 2 and a retort cover 3. The barrel body 2 is arranged on the retort 1, the retort 1 is installed on the bottom pot 4, and the retort cover 3 is covered on the barrel body 2. The grate 1 includes a grate body 10, and a plurality of air inlet holes are uniformly arranged on the grate body 10, and the air inlet holes are provided with protrusions 100. The protrusions 100 are hollow structures. The hollow part of the protrusions 100 and the air inlet holes The two sides of the protrusion 100 are provided with ventilation holes 101, and the protrusion 100 is covered with a layer of non-woven fabric. The barrel body 2 includes at least an upper barrel body 20 and a lower barrel body 21, an upper barrel body 20 and a lower barrel body A sealing gasket 5 is provided at the junction of 21.

[0029] In this embodiment, a protrusion is provided on the grate body, and vent holes are opened on both sides of the pr...

Embodiment 2

[0031] This embodiment includes a bottom pot 4, a retort grate 1, a barrel body 2 and a retort cover 3. The barrel body 2 is arranged on the retort 1, the retort 1 is installed on the bottom pot 4, and the retort cover 3 is covered on the barrel body 2. The grate 1 includes a grate body 10, and a plurality of air inlet holes are uniformly arranged on the grate body 10, and the air inlet holes are provided with protrusions 100. The protrusions 100 are hollow structures. The hollow part of the protrusions 100 and the air inlet holes The two sides of the protrusion 100 are provided with ventilation holes 101, and the protrusion 100 is covered with a layer of non-woven fabric. The barrel body 2 includes at least an upper barrel body 20 and a lower barrel body 21, an upper barrel body 20 and a lower barrel body A sealing gasket 5 is provided at the junction of 21.

[0032] The top walls of the upper barrel 20 and the lower barrel 21 are provided with a sawtooth-shaped liquid collectin...

Embodiment 3

[0035] This embodiment includes a bottom pot 4, a retort grate 1, a barrel body 2 and a retort cover 3. The barrel body 2 is arranged on the retort 1, the retort 1 is installed on the bottom pot 4, and the retort cover 3 is covered on the barrel body 2. The grate 1 includes a grate body 10, and a plurality of air inlet holes are uniformly arranged on the grate body 10, and the air inlet holes are provided with protrusions 100. The protrusions 100 are hollow structures. The hollow part of the protrusions 100 and the air inlet holes The two sides of the protrusion 100 are provided with ventilation holes 101, and the protrusion 100 is covered with a layer of non-woven fabric. The barrel body 2 includes at least an upper barrel body 20 and a lower barrel body 21, an upper barrel body 20 and a lower barrel body A sealing gasket 5 is provided at the junction of 21.

[0036] The top walls of the upper barrel 20 and the lower barrel 21 are provided with a sawtooth-shaped liquid collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com