Step-by-step vacuum evaporating method for purifying lithium metal

A technology for purifying metal and metal lithium, applied in the direction of improving process efficiency, can solve the problems of low impurity collection rate, increasing the number of equipment, long production cycle, etc., to achieve the effect of simple process, quality assurance, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

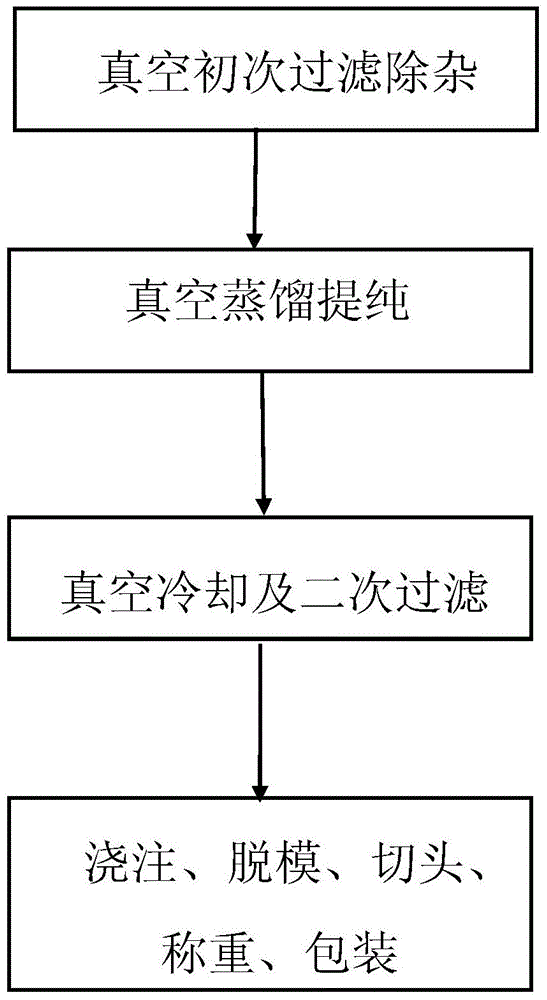

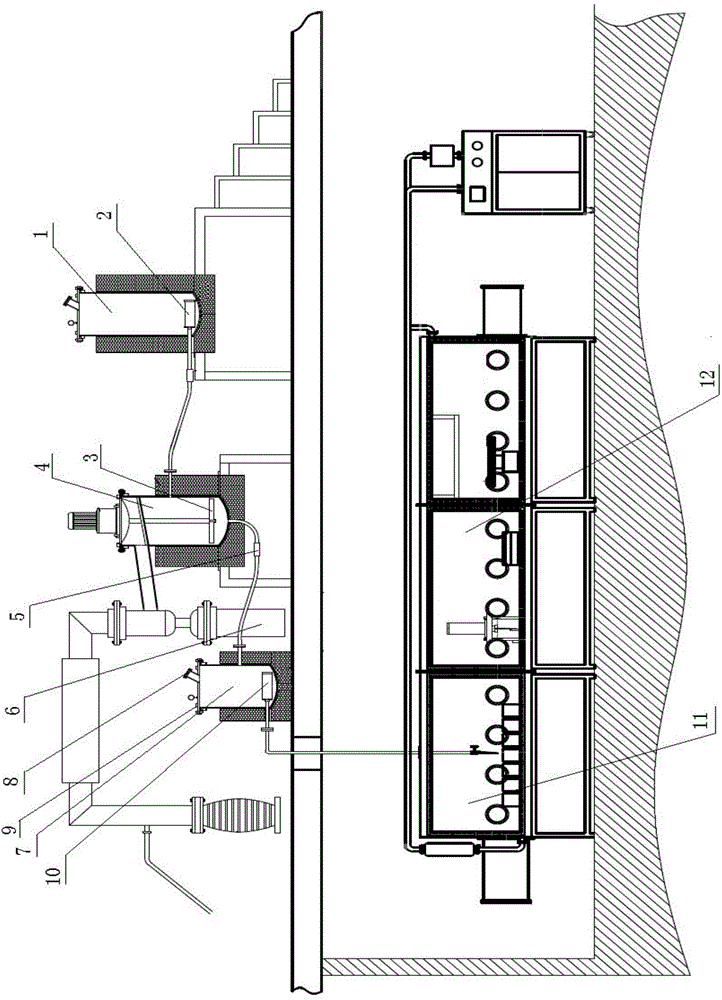

[0021] As shown in the figure, process engineering of the present invention is:

[0022] The metal lithium extracted by electrolysis is put into the feeding furnace 1 of the vacuum melting furnace, wherein the purity of the metal lithium is 99%. After putting it away, close the door, and continuously vacuumize the cavity of the feeding furnace 1. The temperature is 200 ℃ ~ 300 ℃, the vacuum degree is 10 -1 Pa~10 -3 Under the condition of Pa, metal lithium is melted until it melts into a liquid state; the metal lithium liquid is filtered through filter I2;

[0023] The molten metal lithium liquid enters the vacuum distillation furnace 4 through the filter I2 and the pipeline, heats and evacuates, stirs the metal lithium liquid with the stirring paddle 3, increases the surface area of the liquid, and accelerates evaporation. degree is 10 -1 Pa~10 -3 Under the condition of Pa, the potassium and sodium contained in the metal lithium liquid are evaporated, and the evaporated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com