Method for producing relaxor ferroelectric single crystal PMN-PT by using vertical freezing technology

A technology of relaxor ferroelectric single crystal and production method, which is applied in the field of ceramic crystallization and can solve the problems of high cost and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

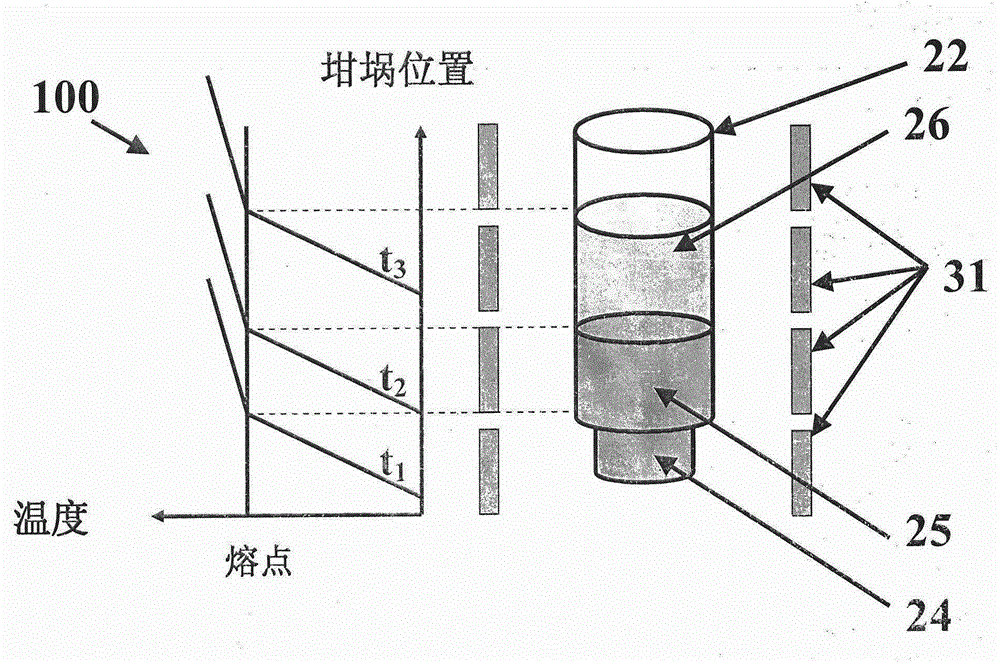

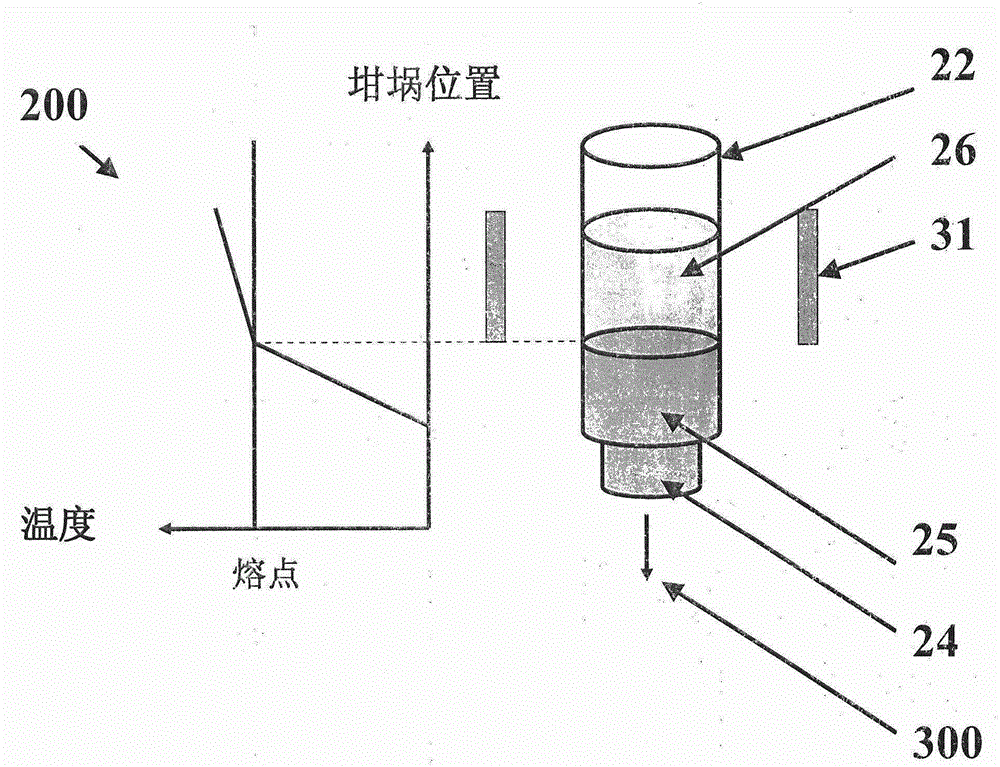

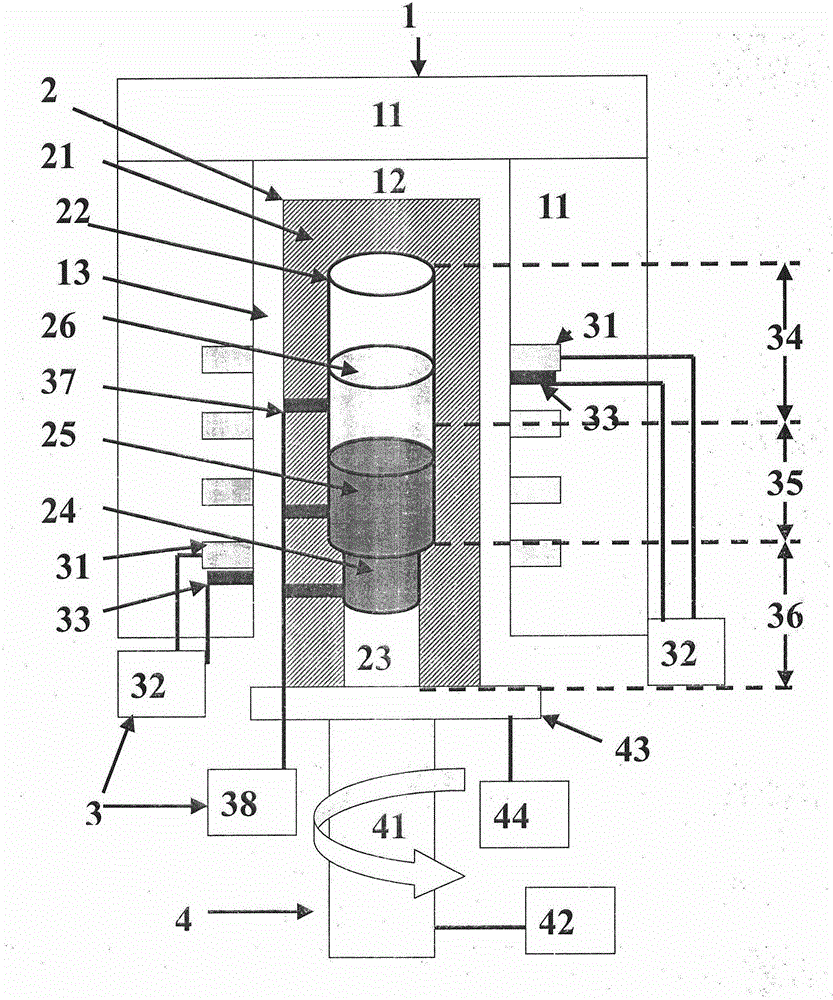

[0013] Referring to accompanying drawing, compare vertical solidification method to grow PMN-PT crystal ( figure 1 ) and the traditional Bridge drop method to grow PMN-PT crystals ( figure 2 ) similarities and differences: the first, in the vertical solidification method, the crystal crucible (22) does not do mechanical movement relative to the electric furnace heater (31); 31) Vertical downward movement (300); second, in the vertical solidification method, the electric furnace has more than 3 sets of heaters (31) independently controlled, so that the same crystallization temperature zone curve (100) can be obtained in different time periods of crystallization (t 1 , t 2 , t 3 ...) moves vertically upwards relative to the electric furnace heater (31); and in the Bridge descent method, there is usually only one group of heaters (31), and the crystallization temperature zone curve (200) formed will not change over time Change. In summary, the vertical solidification method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com