Temperature sensor applied to metering ammeter and temperature trimming method thereof

A technology of temperature sensors and counters, which is applied to thermometers, thermometers, and electrical devices that use directly heat-sensitive electric/magnetic elements, and can solve the problem of reducing the chip area of analog circuits, inaccurate gain changes, and excessive capacitance ratios and other issues to achieve the effect of avoiding competition and risk-taking, reducing design cost and complexity, and being easy to match

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

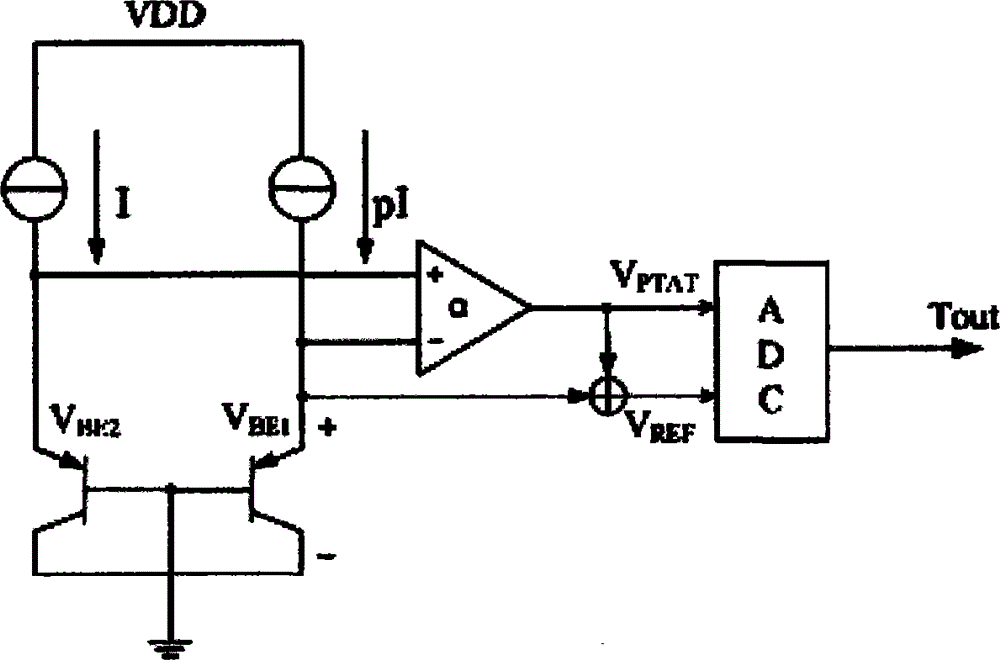

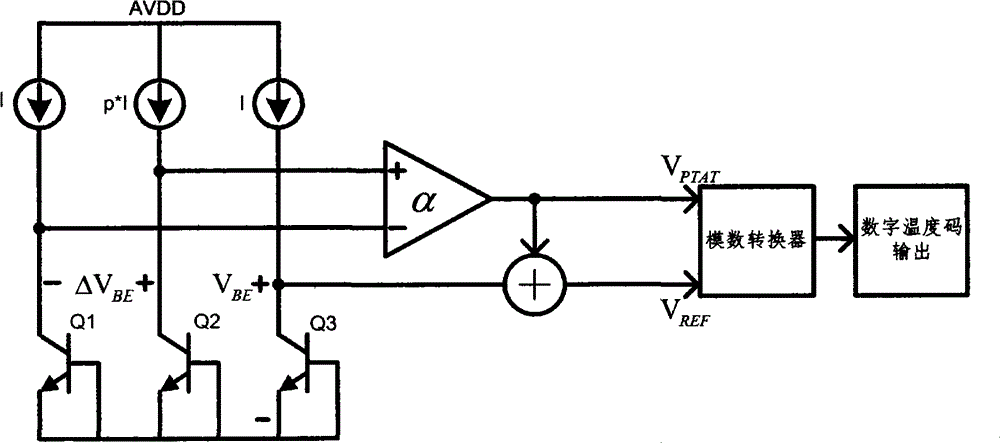

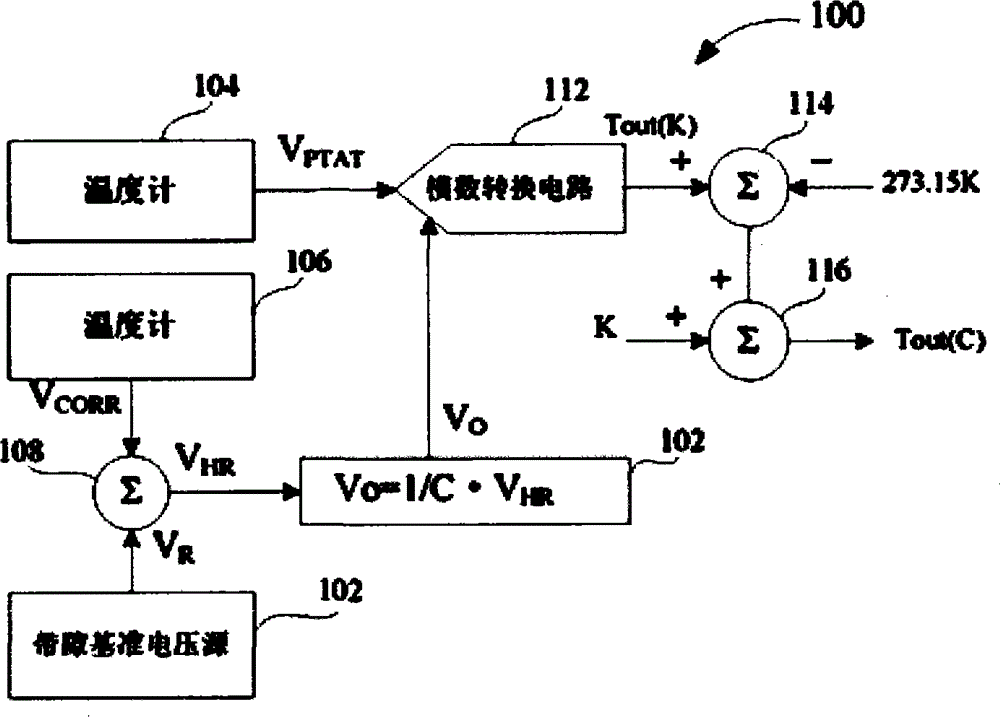

[0027] See attached figure 1 and 3 They are schematic circuit diagrams of common temperature sensing methods in the prior art. attached figure 2 Shown in is the basic principle of the temperature sensor used in the present invention, by ΔV BE with V BE The combination of produces the reference voltage V REF , using a voltage proportional to temperature V PTAT and a temperature-independent reference voltage V REF The ratio to determine the temperature value, and then through the formula:

[0028] T=Aμ+B (1)

[0029] Get the temperature in Celsius. This formula is used to calculate the temperature in Celsius, where: T represents the calculation result in degrees Celsius; μ represents the positive temperature coefficient (that is, α△V BE ) at zero temperature coefficient (i.e. V BE +α△V BE); A and B are constants, and the standard v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com