Quantitative determination method for surface chalking of inorganic non-metallic materials

An inorganic non-metal, quantitative measurement technology, applied in the direction of material absorption and weighing, can solve the problem of not directly reflecting the degree of pulverization, and achieve the effect of easy operation, quick acquisition and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

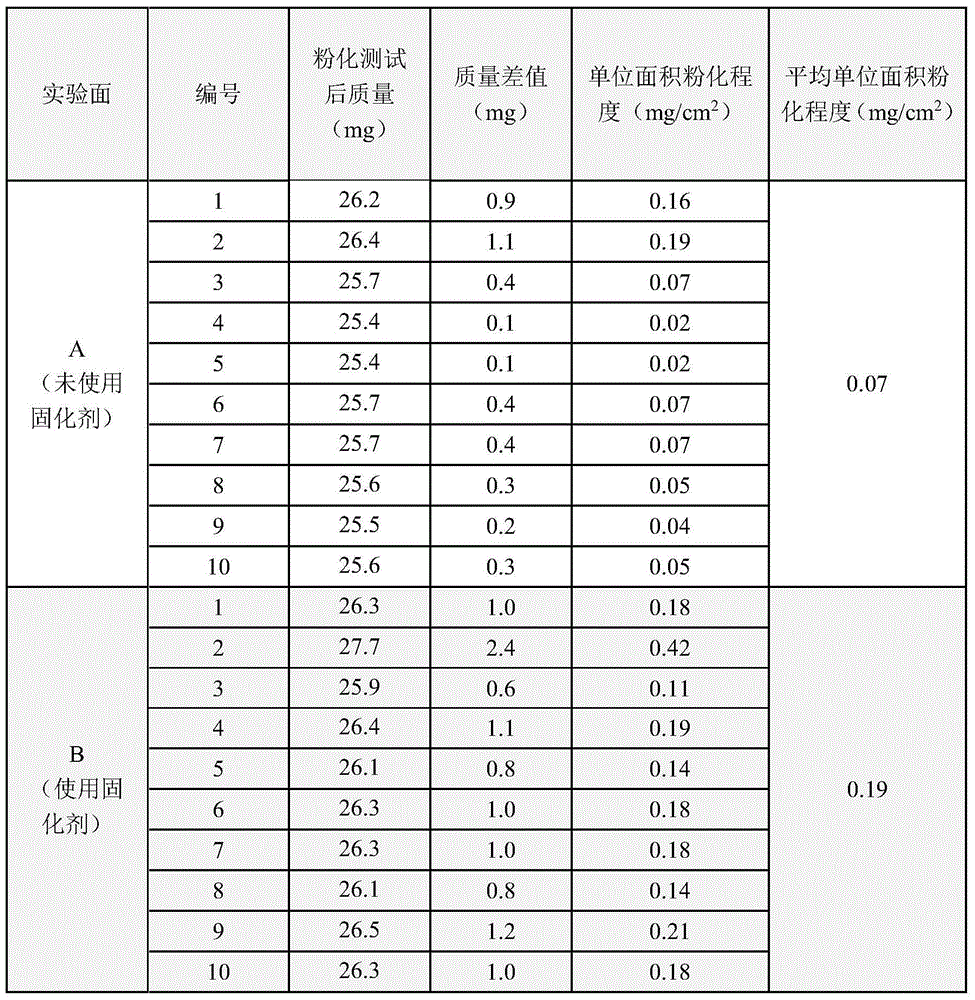

[0034] in-lab test

[0035] The purpose of this example is to simulate a chalked surface and evaluate the effect of the curing treatment.

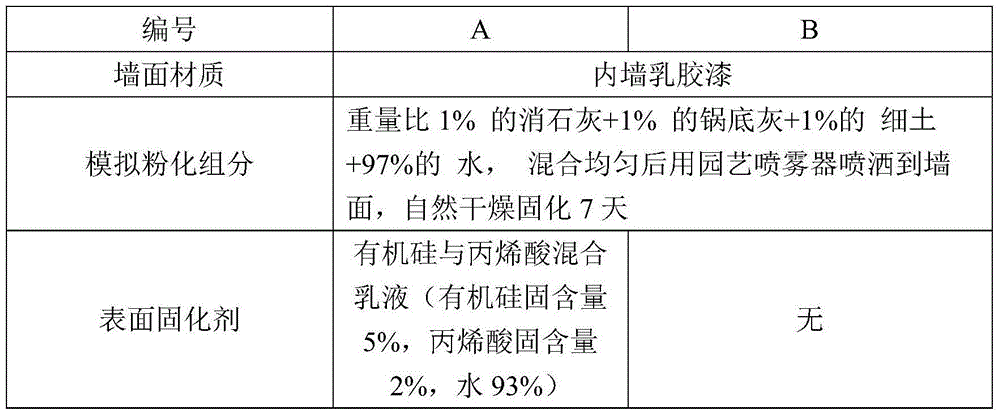

[0036] The experimental area and materials used are listed in Table 1.

[0037] Table 1 Division of laboratory experiment areas

[0038]

[0039] Experimental steps:

[0040] ① Preparation of experimental background

[0041] Take 10g of slaked lime, 10g of pot bottom ash and 10g of raw soil, add 1000g of water and stir for 10 minutes with a speed of 500r / min;

[0042] After passing through a 120-mesh sieve, put it into a pressure watering can, and evenly spray it on the lime plastered wall. After curing, spray it 3 times and let it dry naturally for 2 days;

[0043] After removing the floating dust on the surface with a brush, spray the left area A with curing agent and let it dry naturally for 1 day;

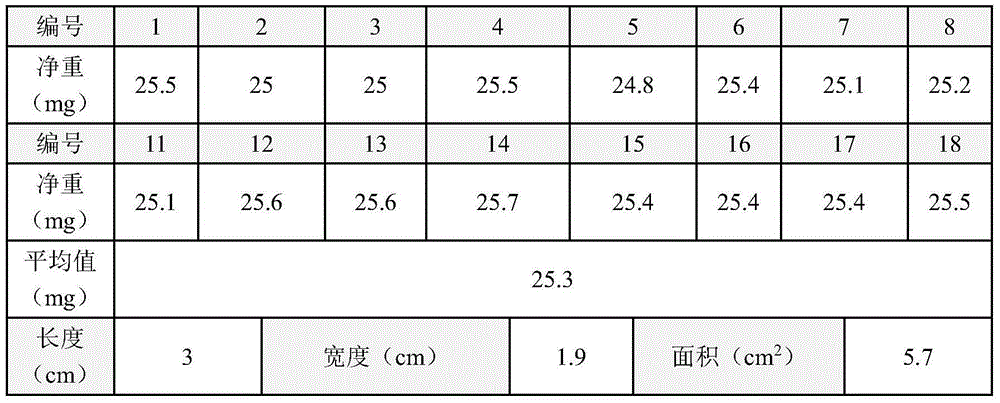

[0044] ②Clean the glass slide with alcohol, spread the 3M adhesion test tape on the glass slide, cut it with a 3cm grid knife, cla...

Embodiment 2

[0056] Quantitative determination of pulverization degree on the surface of Liu's House Ancestral Hall in Jinggang Mountains without slogans

[0057] Built in 1824, the limestone surface of Liu's House Ancestral Hall in Jinggangshan has been pulverized, and some of the Red Army's revolutionary slogans have fallen off. The purpose of this example is to measure the degree of pulverization of facades with different orientations before the solidification protection construction is officially carried out.

[0058] Experimental steps:

[0059] ① Select test sites on the west, south and east facades of Liu's House Ancestral Hall. The surface to be tested is required to be basically flat, free from plaster peeling and serious deterioration, and free from damp efflorescence and plant diseases;

[0060] ②Clean the glass slide with alcohol, spread the 3M adhesion test tape on the glass slide, cut it with a 3cm grid knife, clamp it into the analytical balance with tweezers, weigh the mas...

Embodiment 3

[0069] Jinggangshan slogan solidification No. 1 experimental surface

[0070] The purpose of this example is to quantitatively test the pulverization degree of the plastered surface of the west facade of Liu's House in Jinggangshan after applying different surface inorganic curing agents.

[0071] Experimental steps:

[0072] ① Select the experimental area on the facade of Liu's House Ancestral Hall, avoiding the revolutionary slogans with high value that need to be protected, and make the surface as smooth as possible. Use a brush to remove surface dust;

[0073] ② Spray ethyl silicate ES in the experimental areas of A, B and C;

[0074] ③ After the ethyl silicate ES is solidified, spray anhydrous micron lime NML-010 in the experimental area B;

[0075] ④ After the anhydrous microlime NML-010 is solidified, spray ethyl silicate ES in the experimental area C;

[0076] ⑤ Clean the glass sheet with alcohol, spread the 3M adhesion test tape on the glass sheet, cut it with a 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com