Large-format light curing 3D printer

A 3D printer, surface light technology, applied in the direction of additive processing, etc., can solve the problems of technical accuracy and printing speed gap, affect processing speed, affect the accuracy of molded parts, etc., to achieve the effect of high power density, elimination of obstacles, and accurate molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] First of all, it must be pointed out that this embodiment is only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

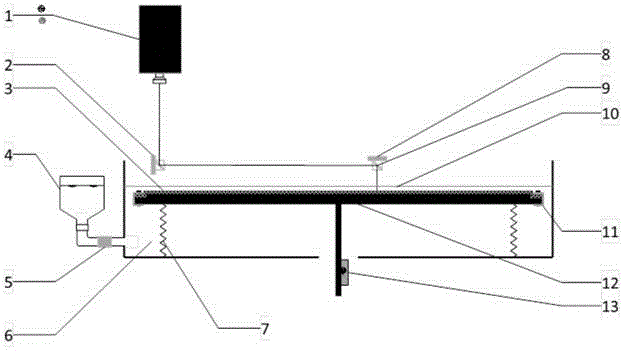

[0024] The overall platform device such as figure 1 When installing and connecting, ensure that the Z-axis platform is parallel to the horizontal plane and ensure that the movement direction is perpendicular to the horizontal plane. Place the base plate on the Z-axis platform, and fix it with the Z-axis platform with a fixing piece. The beam emitted by the ultraviolet laser is shaped and then focused on the upper surface of the base plate through the mirror, which is used as the initial position of the platform. Pour photosensitive resin into the liquid replenishment tank, and control the page height of the liquid replenishment tank and the liquid storage pool through a computer-controlled pressure device. Complete the preparatory work before curing.

[0025] Use 3D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com