Gas Station Load Automatic Control System

A technology of automatic control system and gas station, which is applied in the direction of control/regulation system, non-electric variable control, fluid pressure control, etc. It can solve the problem of large difference in the amount of air mixed with gasification agent, increasing the difficulty of gas furnace operation, and gas furnace Unstable furnace conditions and other problems, to achieve the effect of eliminating potential safety hazards, stabilizing adjustments, and eliminating ultra-high and ultra-low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

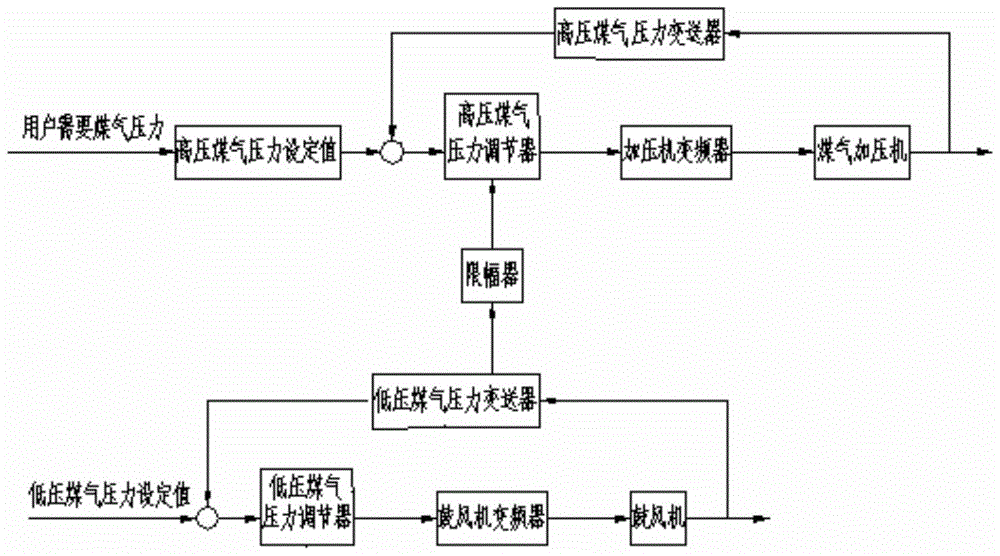

[0025] Such as figure 1 As shown, the gas station load automatic control system provided by Embodiment 1 of the present invention has a high-pressure gas pressure control circuit, a low-pressure gas pressure control circuit and a limiter; the low-pressure gas pressure control circuit includes a low-pressure gas pressure transmitter and sequentially connected A low-pressure gas pressure regulator, a blower frequency converter and a blower, the low-pressure gas pressure regulator is connected with the industrial computer to obtain the low-pressure gas pressure setting value sent by the industrial computer, and the low-pressure gas pressure transmitter is set on the low-pressure gas On the conveying channel, and connected with the low-pressure gas pressure regulator, the measured actual low-pressure gas pressure value is fed back to the low-pressure gas pressure regulator; the low-pressure gas pressure transmitter also communicates with the high-pressure gas pressure through the l...

Embodiment 2

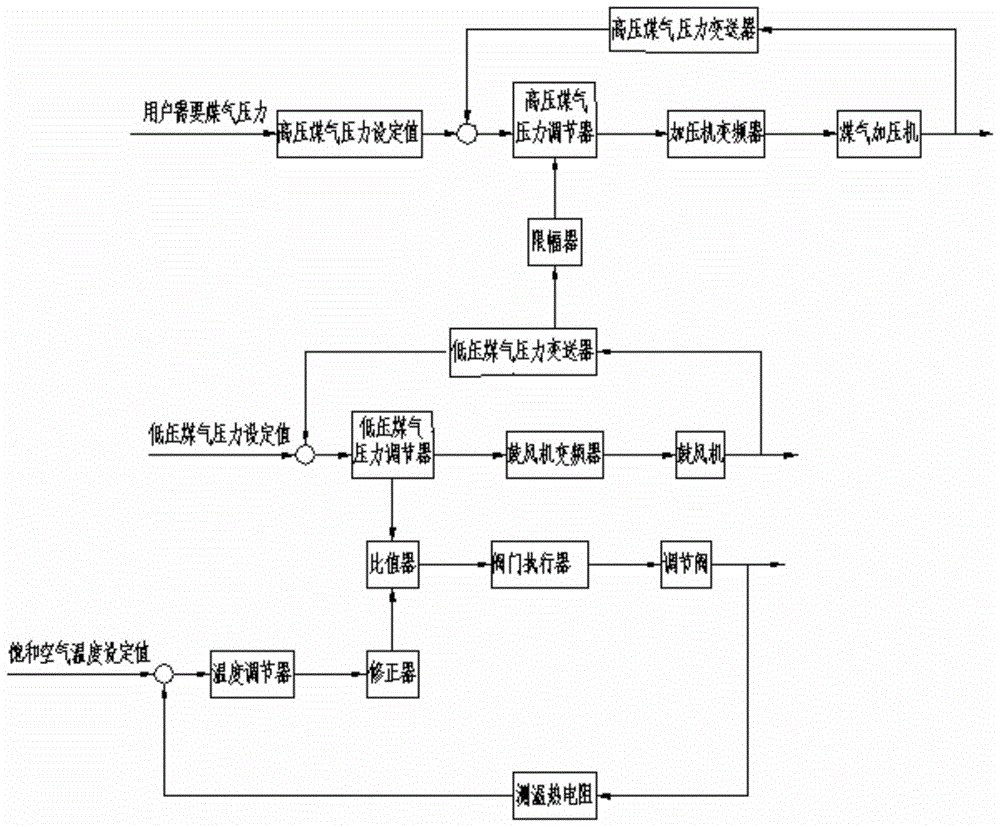

[0030] Such as figure 2 As shown, on the basis of Embodiment 1, the gas station load automatic control system of the present invention also includes a saturated air temperature control loop, which includes a ratio controller, a valve actuator, and a steam volume regulating valve connected in sequence. The ratio device is connected to the low-pressure gas pressure regulator, and the steam volume regulating valve is arranged on the steam conveying channel, and the steam volume regulating valve is specifically an electric regulating valve with a linear characteristic.

[0031] Further, the saturated air temperature control loop also includes a temperature regulator, a corrector and a temperature measuring thermocouple, the temperature regulator, corrector and ratio are connected in sequence, and the temperature regulator is connected to the industrial computer to obtain the temperature of the industrial computer. The set value of the saturated air temperature is sent, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com