Constant-volume firebomb system for simulating combustion of engine

A constant-volume incendiary bomb and engine technology, applied in the direction of internal combustion engine testing, etc., can solve problems such as difficulty in observing the flame combustion process and difficulty in charcoal smoke, and achieve the effect of low cost and avoiding mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The present invention will be further described in detail below through specific embodiments. The following embodiments may enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any form.

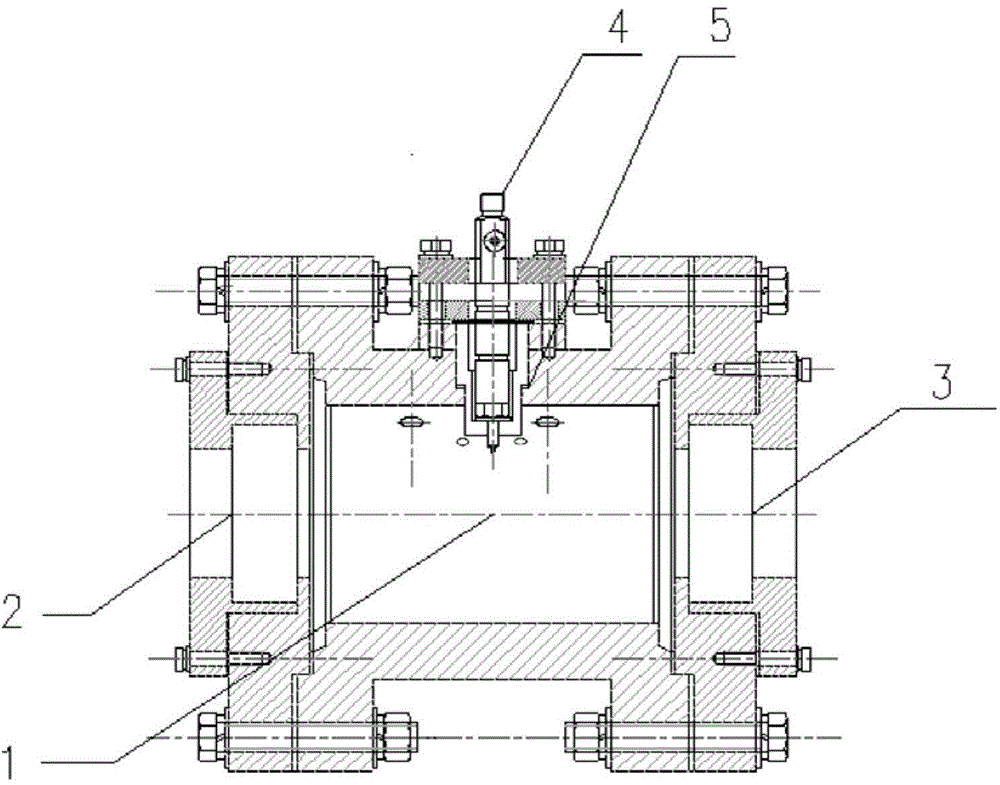

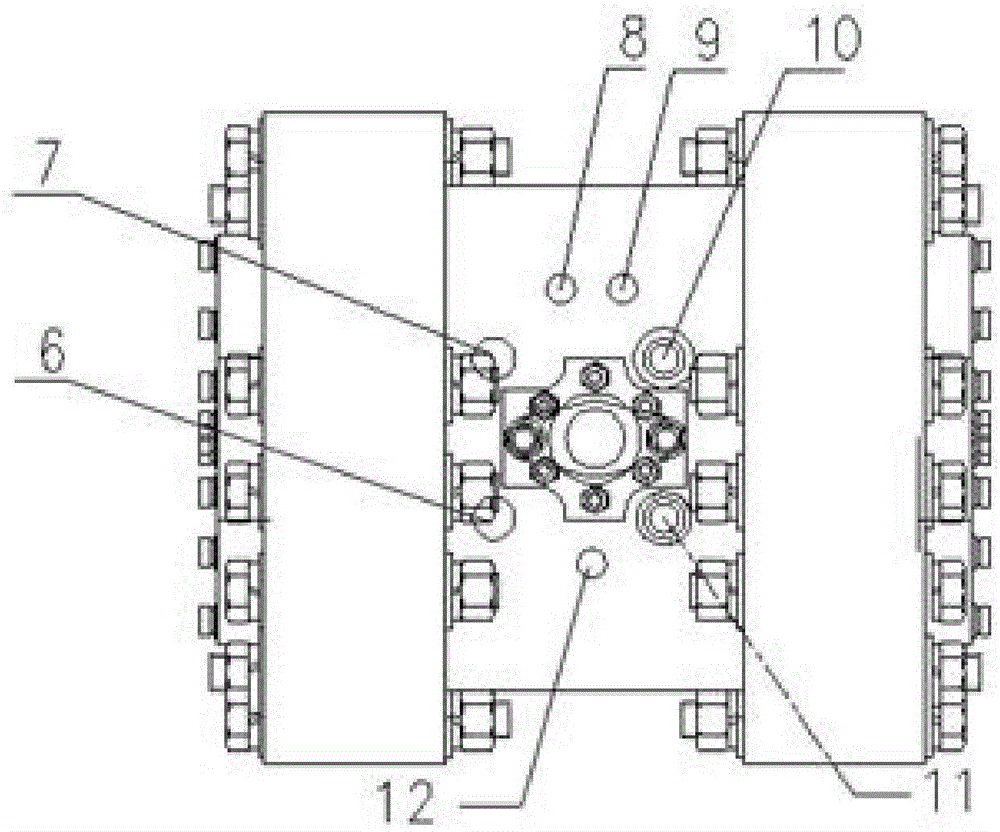

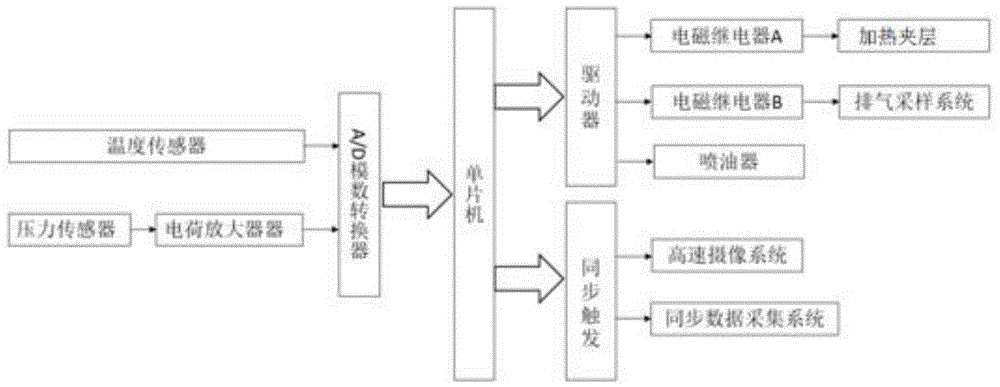

[0032] Such as Figure 1-3 As shown,

[0033] The constant volume combustion bomb system that simulates engine combustion includes:

[0034] Combustion bomb with a cylindrical cavity. The combustion bomb is normalized forged with 16MnRE steel to form a uniform high-temperature and iso-volume high-temperature and high-pressure environment, which can simulate the high-temperature, high-pressure, and constant-pressure conditions of the diesel engine piston at the top dead center position. Containment environment; the two end faces of the combustion bomb body are respectively installed with high-temperature and high-pressure-resistant high-transmittance quartz glass to form an optical path. The high-transmission quar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com