Automatic integration equipment used for paint production

An integrated equipment and paint technology, applied in the direction of chemical instruments and methods, dissolving, mixing machines, etc., can solve the problems of reducing the effect of dispersing aids, lack of fluidity, difficult to mix, etc., to achieve accurate preparation and addition operations, reduce The labor intensity of workers and the effect of saving post-processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

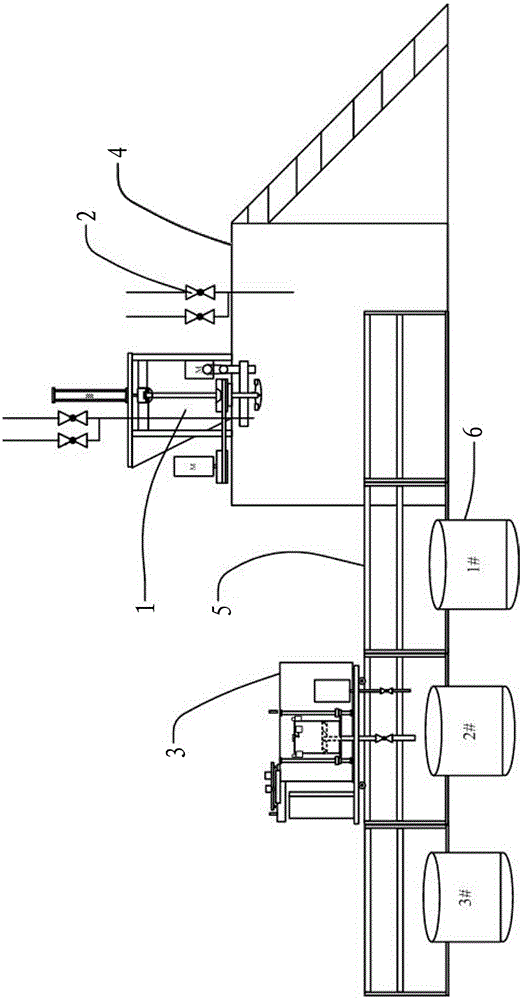

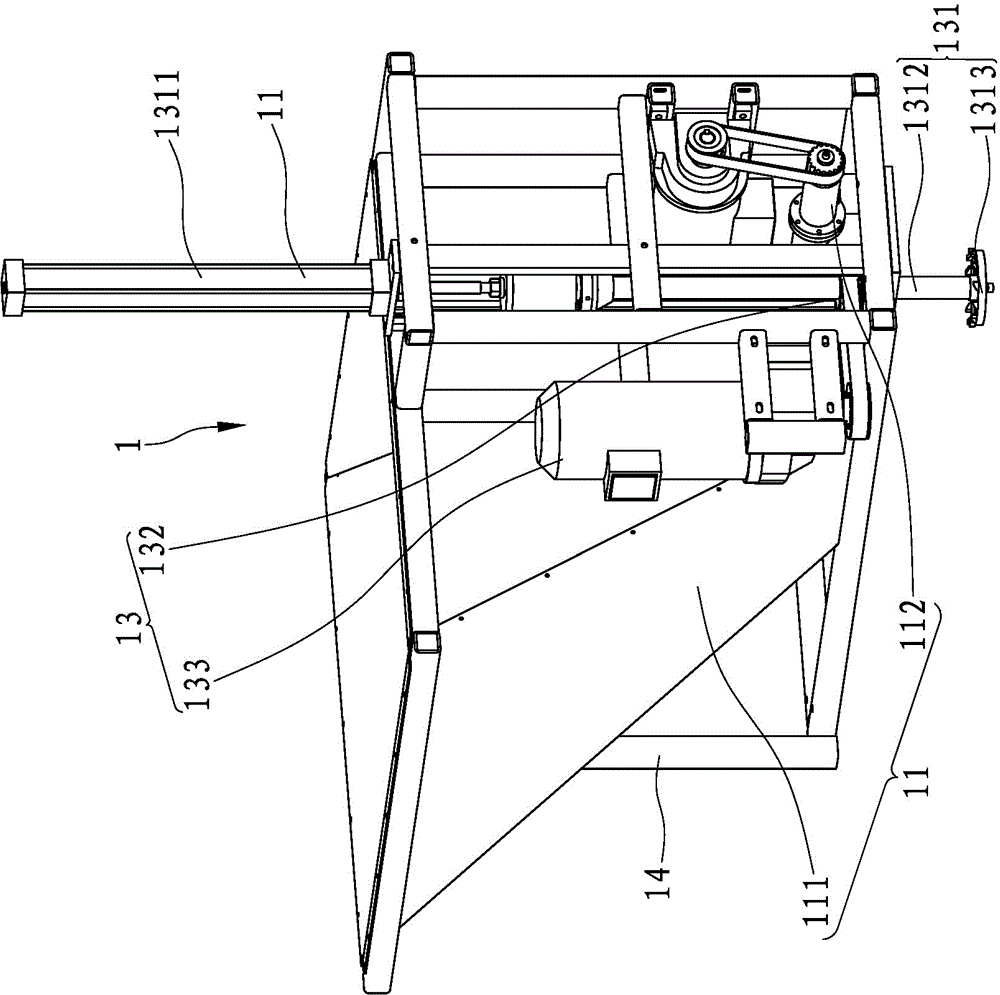

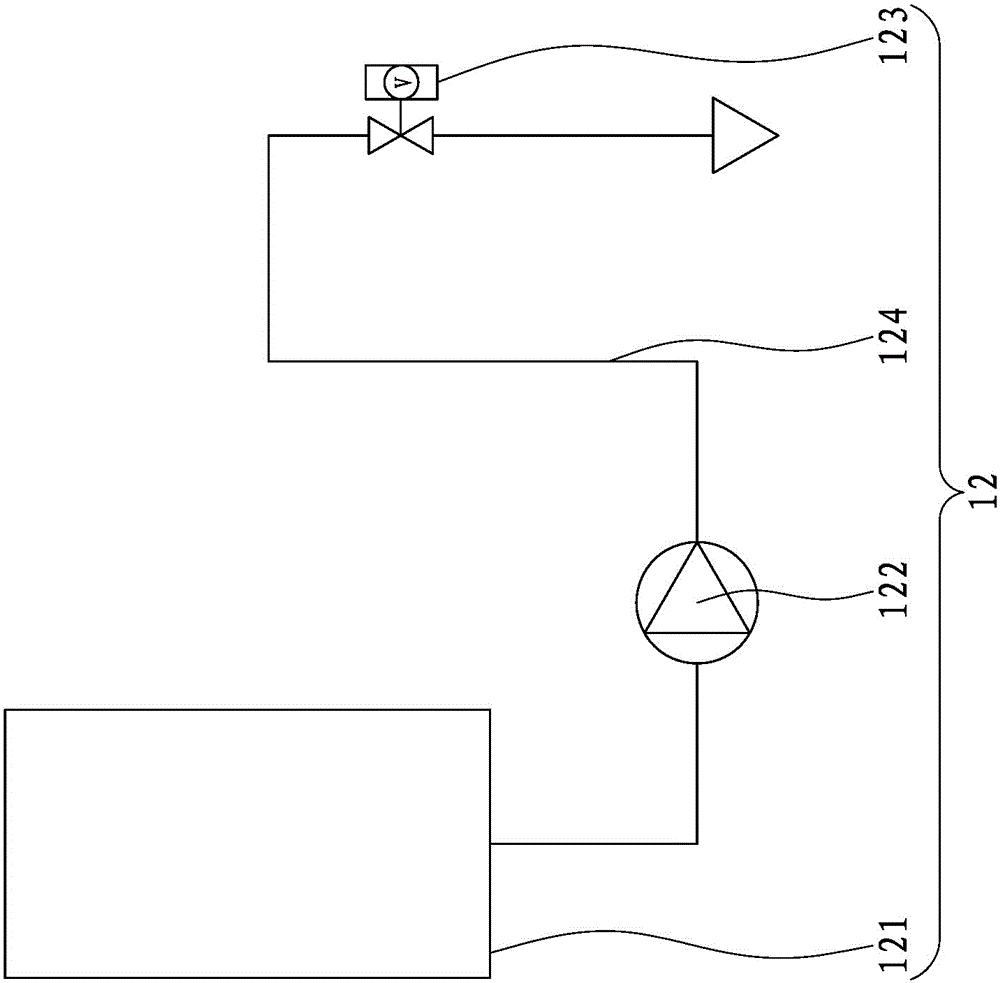

[0028] Such as figure 1 As shown, the present invention is a kind of automatic integrated equipment for paint production, comprising bentonite slurry preparation system 1, auxiliary agent addition preparation system 2, auxiliary agent automatic feeding rail intelligent trolley 3, frame 4, guide rail frame 5 and A comprehensive automation control integration device formed by integrating the automation control subsystems of the above-mentioned subsystems.

[0029] The guide rail frame 5 is installed on one side of the frame 4, the bentonite slurry preparation system 1 and the auxiliary agent addition preparation system 2 are all installed on the top of the frame 4, and the auxiliary agent automatic feeding rail smart car 3 is moved Slidingly connected on the guide rail frame 5, the feeding cylinder of the auxiliary agent automatic feeding rail intelligent trolley 3 can move back and forth along the guide rail frame 5 and move to a position corresponding to the stirring impeller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com