Temperature sensitive graphene-based gold-platinum core-shell bimetallic catalyst and preparation method thereof

A bimetallic catalyst, graphene technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to reduce mass transfer resistance, the preparation method process is simple, repeatable good usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of thermosensitive type graphene foundation-platinum core-shell bimetallic catalyst of the present invention comprises the steps:

[0025] 1) Take a chemically reduced graphene aqueous solution with a concentration of 0.8-1.5mg / mL, add an aqueous solution of chloroauric acid with a concentration of 8-12mmol / L according to the mass ratio of graphene to gold ions of 1:0.07-0.258, and stir and mix for 30- After 120 minutes, heat up to 80-100°C, then add sodium citrate aqueous solution with a concentration of 8-12mmol / L to the mixed solution at a ratio of 1:1-2 molar ratio of gold ions to sodium citrate, and react for 30-120 minutes. Then add 8-12mmol / L silver nitrate aqueous solution according to the molar ratio of chloroauric acid to silver nitrate 1:0.67-1.5, react for 30-120min, then press the molar ratio of silver nitrate to potassium tetrachloroplatinite 1:1 Add an aqueous solution of potassium tetrachloroplatinite with a concentration of 8-12mm...

Embodiment 1

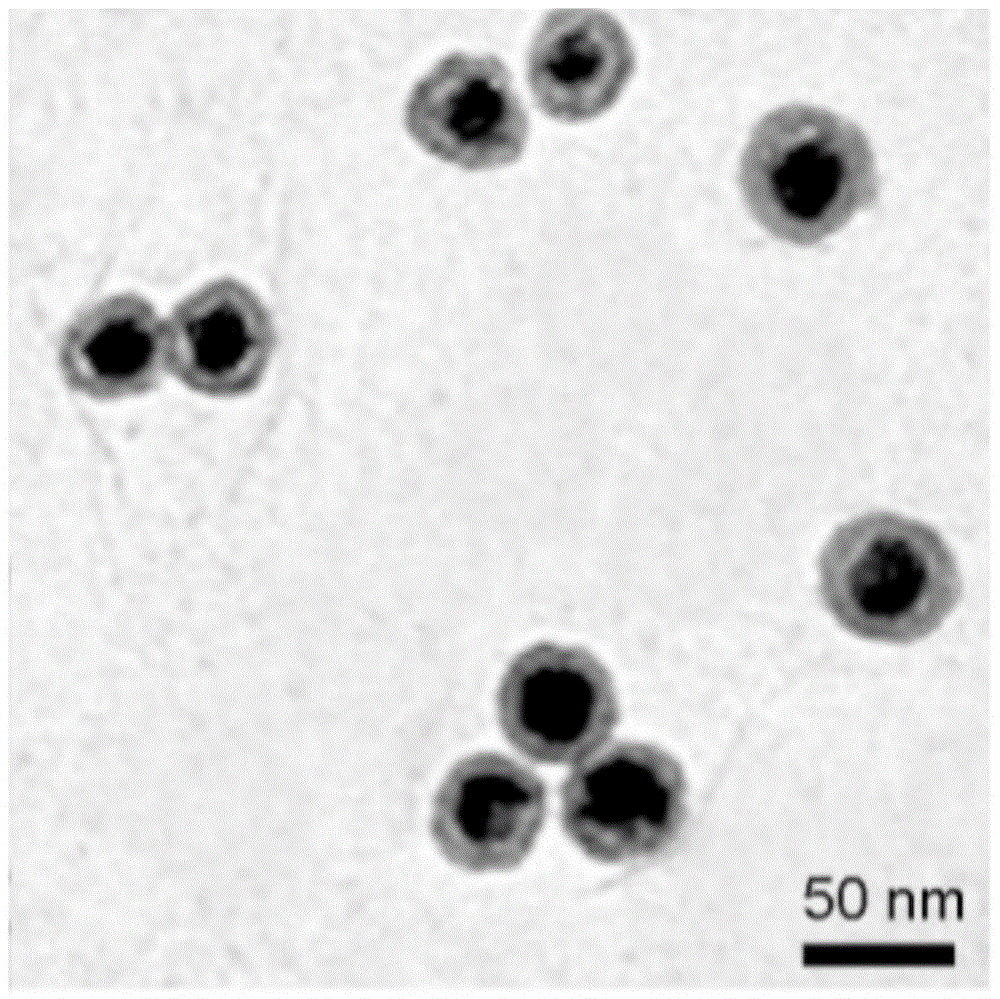

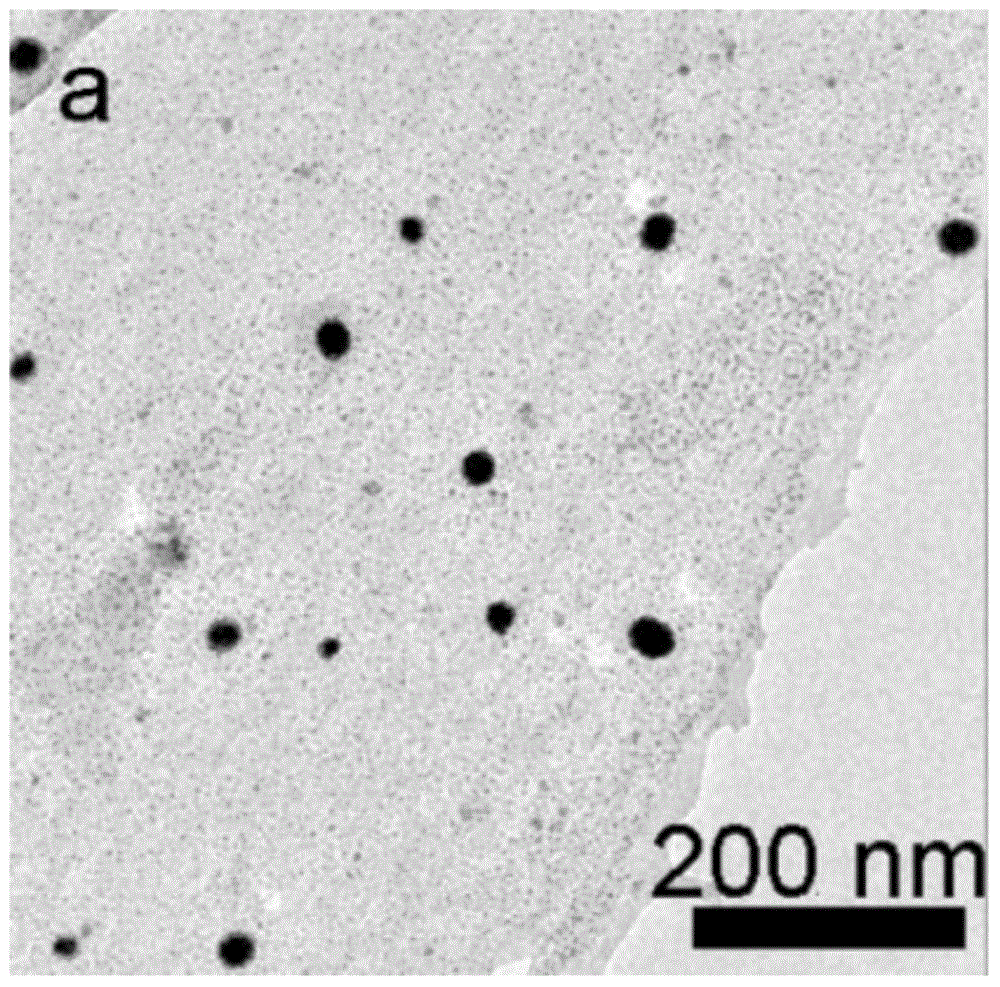

[0030] (1) Take 30mL of chemically reduced graphene with a concentration of 1mg / mL and add it to the reaction vessel, add 3.3mL of chloroauric acid solution with a concentration of 10mmol / L, heat the reaction vessel to 80°C, and then add 6.6mL with a concentration of 10mmol / L L of sodium citrate aqueous solution, keep this temperature for 60min, then add dropwise 3.3mL silver nitrate solution with a concentration of 10mmol / L to the solution, keep it at 80°C for 60min, then add 3.3mL with a concentration of 10mmol / L dropwise to the solution The aqueous solution of potassium tetrachloroplatinite was kept at 80°C for 3 hours, and then the product was centrifuged and washed until the supernatant pH = 7, and the precipitate was freeze-dried at -50°C to obtain a temperature-sensitive graphene-platinum core-shell double Metal catalyst precursor, its TEM characterization results are as follows figure 1 shown.

[0031] (2) Dissolve 25mg of polyisopropylacrylamide-grafted dextran in 5m...

Embodiment 2

[0035] (1) Take 50mL of chemically reduced graphene with a concentration of 0.8mg / mL and add it to the reaction vessel, add 1.8mL of chloroauric acid solution with a concentration of 8mmol / L, heat the reaction vessel to 90°C, and then add 3.6mL with a concentration of 8mmol / L of sodium citrate aqueous solution, keep this temperature for 120min, then dropwise add 2.7mL of silver nitrate solution with a concentration of 8mmol / L to the solution, keep the reaction at 90°C for 60min, then add 2.7mL of silver nitrate solution with a concentration of 8mmol / L dropwise to the solution L of potassium tetrachloroplatinite aqueous solution was kept at 90°C for 1.5h to complete the reaction, and then the product was centrifuged and washed until the supernatant pH = 6.8, and the precipitate was freeze-dried at -50°C to obtain a temperature-sensitive graphene-platinum core Shell bimetallic catalyst precursors.

[0036] (2) Dissolve 30 mg of polyisopropylacrylamide grafted dextran in 7.5 mL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com