Reflux type static dust removing device

A technology of electrostatic precipitator and electrostatic generator, which is applied in the field of backflow electrostatic precipitator, can solve the problems of poor sealing effect of dust suppression, poor dust settlement effect, low dust suppression efficiency, etc., and achieves a wide range of function options, good discharge effect, Good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

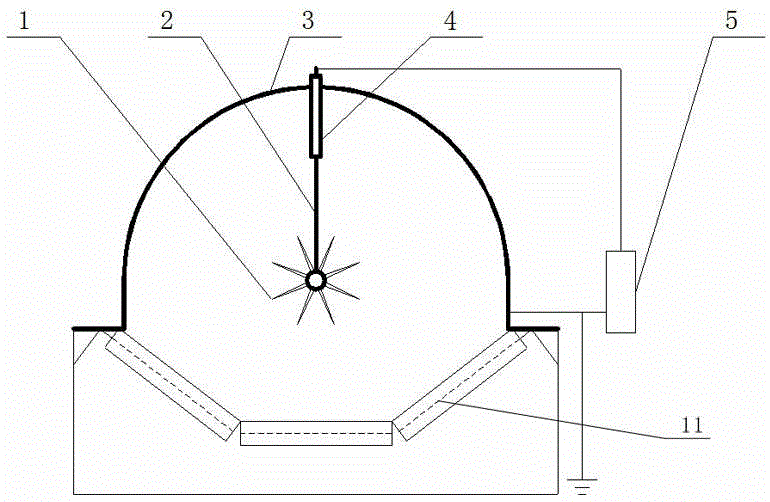

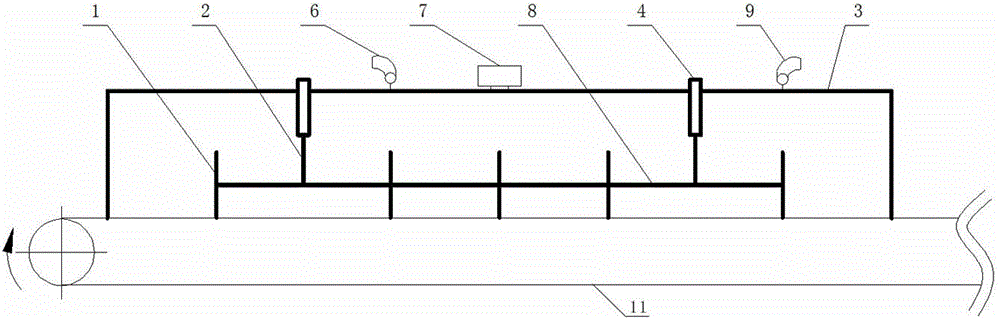

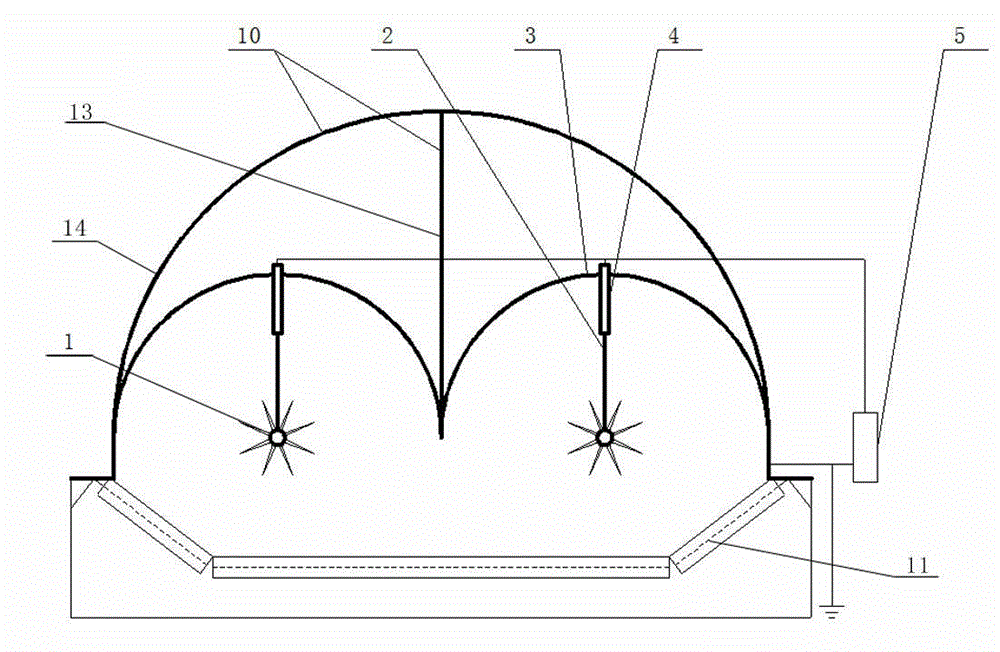

[0029] refer to Figure 1-3 , a return type electrostatic precipitator described in this specific embodiment, comprising a prickly corona wire 1, a boom 2, an Ω-shaped plate 3, an insulating tube 4, an electrostatic generator 5, a return fan 6, and a rapping motor 7. The burr connecting pipe 8 and the exhaust fan 9, the Ω-shaped pole plate 3 is arranged on the upper part of the belt conveyor 11, and several through holes 12 are opened equidistantly on the top of the Ω-shaped pole plate 3, and the insulating tube 4 is arranged in the through hole 12, and the insulating tube 4, one end is located inside the Ω-shaped plate 3, the other end of the insulating tube 4 is located outside the Ω-shaped plate 3, one end of the suspender 2 passes through the insulating tube 4 and connects with the thorn connection tube 8, and the other end of the suspender 2 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com