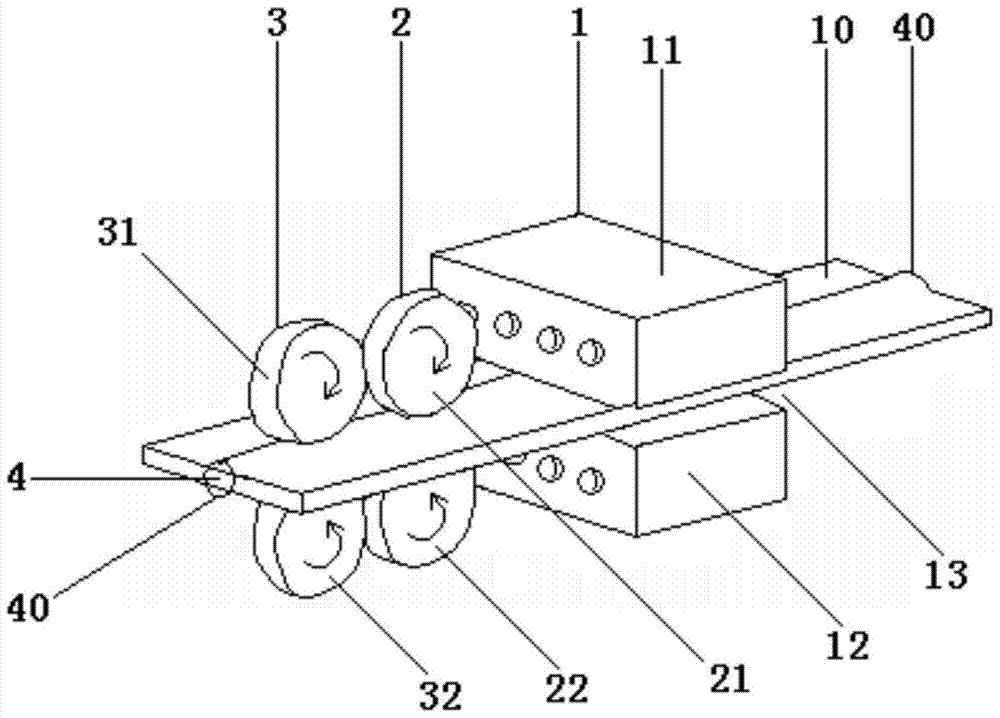

A hot rolling deformation device and process method for processing magnesium alloy welded joints

A technology of welded joints and process methods, applied in welding equipment, metal processing equipment, forming tools, etc., can solve the problems of poor plasticity and low strength of welded joints, and achieve the effects of improving mechanical properties, eliminating residual stress, and improving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Selection of raw materials

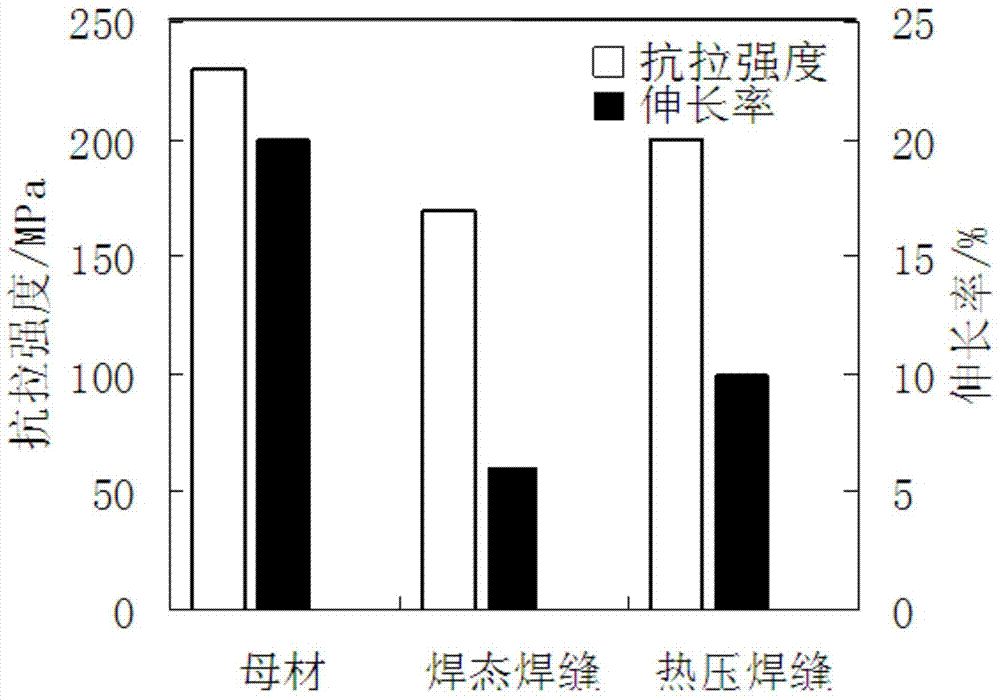

[0052] The Mg-Al series AZ31 magnesium alloy plate is used as the base material for the test. The size of the test plate is 200mm×60mm×3.0mm. The welding material is AZ31 magnesium alloy welding wire with the same quality as the base material, and the specification is φ3.0mm. The main chemical composition and mechanical properties of the magnesium alloy base metal are shown in Table 1 and Table 2.

[0053] Table 1: Chemical composition of AZ31 magnesium alloy (wt.%)

[0054]

[0055] Table 2: Mechanical properties of AZ31 magnesium alloy

[0056]

[0057] (2) Welding method and equipment selection

[0058] A pair of butt welding test plates is composed of 2 plates with a size of 200mm×60mm×3.0mm. The welded test plate has a V-shaped groove of 60°, and the root gap is controlled at 3-4mm. Use acetone to remove oil stains on the surface of the test plate, sand the welding area within 20-30mm until it reveals a metallic luster, sc...

Embodiment 2

[0066] Using the same materials and methods as in Example 1, the size of the test plate is 200mm × 60mm × 3.5mm, the process parameters are: heating temperature T=300°C, the pressure parameters of the main roller group and the auxiliary roller group are respectively 350MPa and 150MPa, heat The pressing speed is 3mm / s.

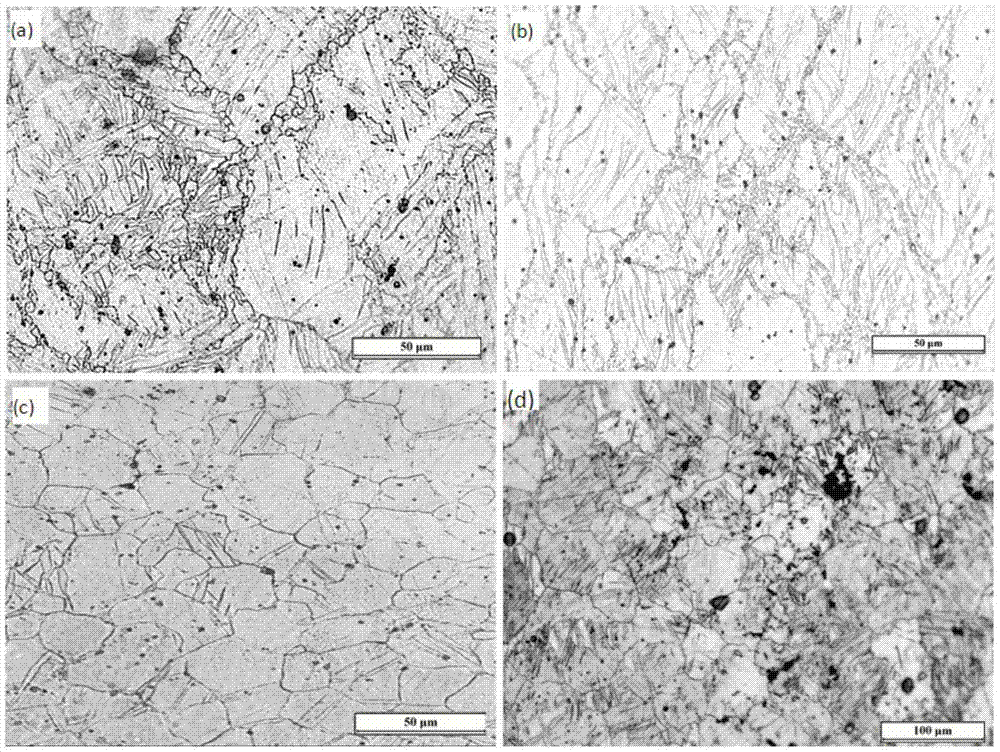

[0067] Such as figure 2 In (b) after deformation at 300 °C, obvious twinning phenomenon began to appear, and very fine dynamic recrystallized grains appeared on the grain boundaries of some original grains. At this point, it can be seen that these grains are obviously elongated, indicating that dynamic recrystallization has started to take place. The room temperature tensile strength and plastic strain of sample (b) reached 176MPa and 7.8%, respectively.

Embodiment 3

[0069] Using the same materials and methods as in Example 1, the size of the test plate is 200mm × 60mm × 4.0mm, the process parameters are: heating temperature T=400°C, the pressure parameters of the main roller group and the auxiliary roller group are respectively 150MPa and 350MPa, heat The pressing speed is 6mm / s.

[0070] Such as figure 2 In (c) after deformation at 400 °C, obvious twinning phenomenon appeared, but there were also phenomena of grain recombination and grain growth, and dynamic recrystallization and grain growth coexisted. The room temperature tensile strength and plastic strain of sample (c) reached 180.8MPa and 8.3%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com