Method for reducing die-casting magnesium alloy melting weld porosity

A weld porosity and fusion welding technology, which is applied in welding equipment, metal processing equipment, laser welding equipment, etc., can solve complex academic and engineering problems, and achieve the effect of reducing porosity, weld porosity, and nitrogen porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

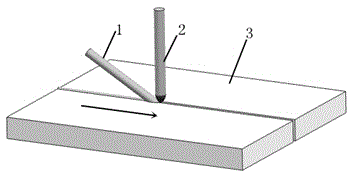

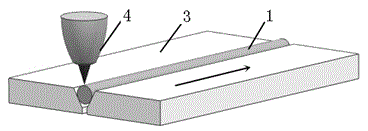

Method used

Image

Examples

example 1

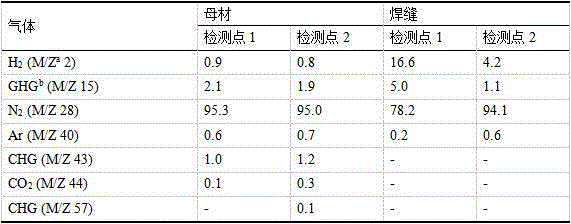

[0033] Reference example 1: The extruded AM60 magnesium alloy welding wire without yttrium element is used as the filler material for welding, and the weld porosity is 30.24%.

Embodiment 1

[0034] Embodiment 1: adopt the AM60 welding wire that contains yttrium element: 3 wt.% to carry out welding as filler material, weld porosity is 21.16%, and porosity reduces 33.87% than reference example 1, comparatively obviously reduces weld seam porosity, welding Quality improved.

Embodiment 2

[0035] Example 2: The AM60 welding wire containing 5 wt.% of yttrium element is used as the filler material for welding. The weld porosity is 18.16%, and the porosity is 39.95% lower than that of reference example 1, which significantly reduces the weld porosity and improves the welding quality. improve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com