Polymer cement waterproof coating

A waterproof coating and polymer technology, applied in the field of polymer cement waterproof coating, can solve the problems of easy cracks on the surface of the coating film, uneven quality of houses, failure of waterproof engineering, etc., and achieve the advantages of high bonding strength and good performance. , Good water and alkali resistance and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

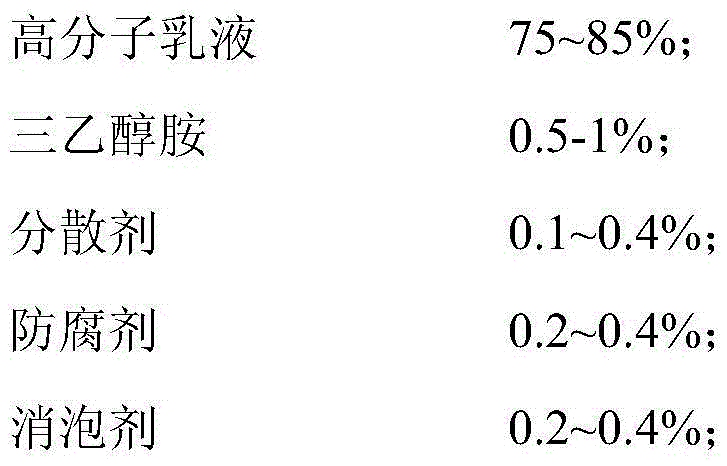

[0041] In this embodiment, the mixing ratio of the liquid material component and the powder material component is 10:10 by weight. According to the national standard, the formula is tested and listed in the table below. In the table below, the sum of the liquid components is 100kg, while the sum of the powder components is 100kg, and the mixing ratio of the two is 10:10.

[0042]

[0043]

Embodiment 2

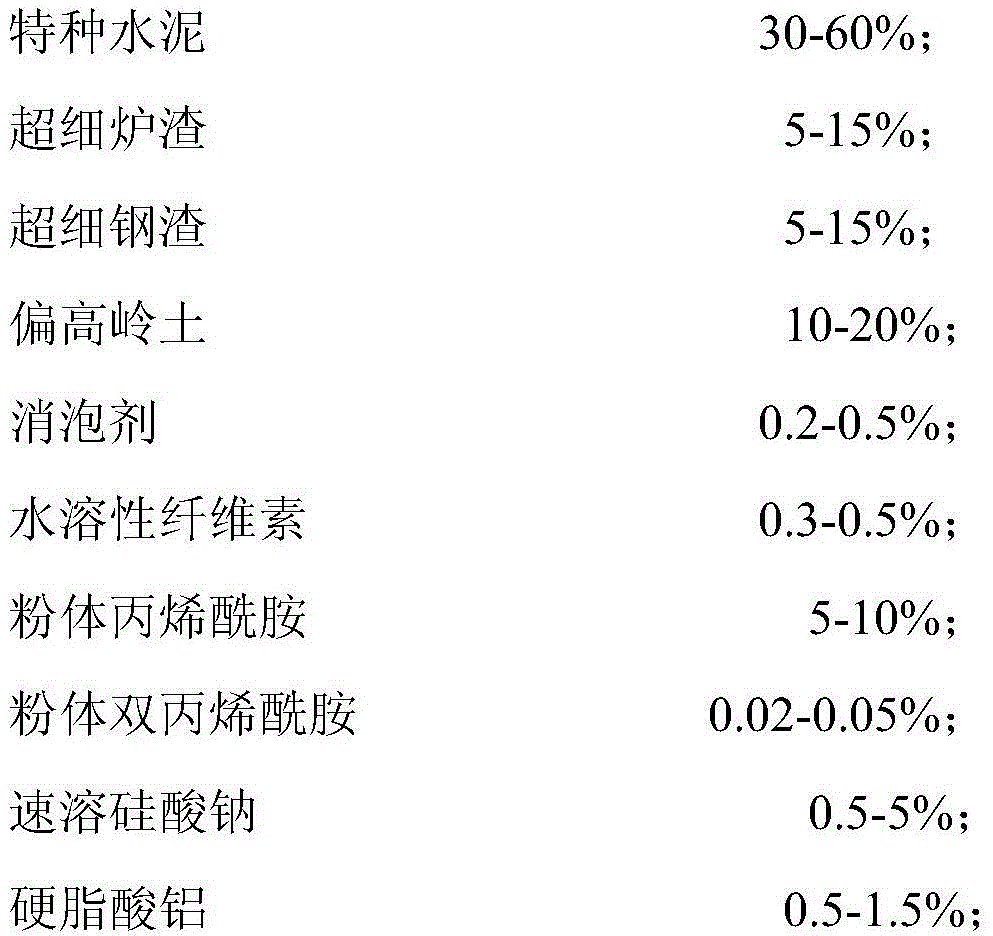

[0045] In this embodiment, the mixing ratio of the liquid material component and the powder material component is 10:10 by weight. According to the national standard, the formula is tested and listed in the table below. In the table below, the sum of the liquid components is 100kg, and the sum of the powder components is 100kg.

[0046]

[0047]

Embodiment 3

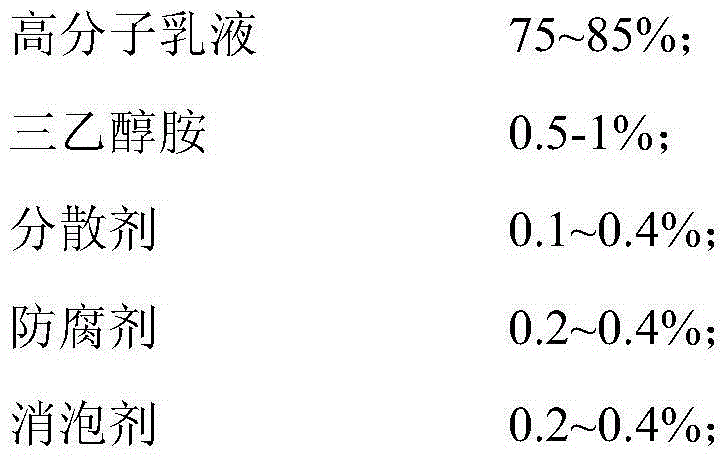

[0049] In this embodiment, the mixing ratio of the liquid material component and the powder material component is 10:10 by weight. According to the national standard, the formula is tested and listed in the table below. In the table below, the sum of the liquid components is 100kg, and the sum of the powder components is 100kg.

[0050]

[0051]

[0052] From Example 1 to Example 3, it can be seen that the polymer cement waterproof coating of the present invention can meet the national standard GB / T 23445-2009 in all preparations, and the impermeability is tested according to GB18445-2012, and has excellent Anti-sagging and anti-cracking properties.

[0053] Simultaneously, the present invention has also carried out comparative test with traditional waterproof paint, and the result is as follows:

[0054]

[0055] As can be seen from the above table, it can be seen from the comparison that the polymer cement waterproof coating of the present invention has obvious ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com