Iron dextran and preparation method thereof

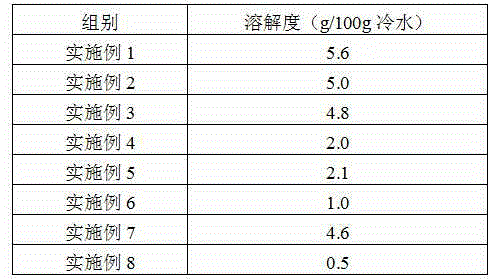

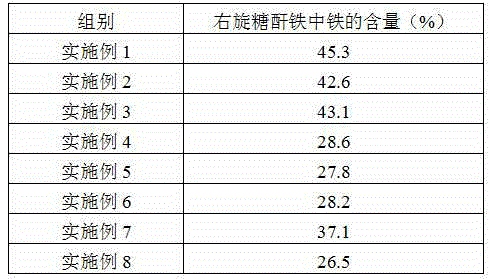

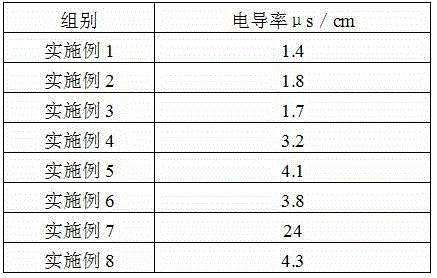

A technology for iron dextran and dextran, which is applied in the field of iron dextran and its preparation, can solve the problems of high macromolecular impurities and ionic impurities, low iron content, low solubility of iron dextran, etc., and achieves reduced content, high purity and good solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of preparation method of iron dextran comprises the steps:

[0022] (1) Put 155kg of purified water into the reaction tank, control the pressure to 0.10 MPa, stir and heat to 80°C, then add 60kg of dextran 20, boil until completely dissolved; add 5.4mol / L hydrochloric acid to adjust the pH of the solution to 4, continue Boil for 1.5 hours, then cool to 38°C, add 10mol / L sodium hydroxide solution to adjust the pH of the hydrolyzate to 6, heat to 70°C, and pass through a 100-mesh sieve to obtain a brown-yellow transparent solution;

[0023] (2) Weigh 38.9kg of ferric chloride and dissolve it with 85kg of purified water, add it to the reaction tank, then add the prepared dextran 20 hydrolyzate, adjust the pH to 11 with 10mol / L sodium hydroxide solution, and control the pressure to 0.10MPa , the solution was heated to boiling, boiled for 1.5 hours, and then cooled to 38°C to obtain the complex solution; then technical means 1 was used for treatment, tha...

Embodiment 2

[0025] Embodiment 2: a kind of preparation method of iron dextran comprises the steps:

[0026] (1) Put 150kg of purified water into the reaction tank, control the pressure to 0.05MPa, stir and heat to 75°C, then add 60kg of dextran 20, boil until completely dissolved; add 5.4mol / L hydrochloric acid to adjust the pH of the solution to 3, continue Boil for 1 hour, then cool to 35°C, add 10mol / L sodium hydroxide solution to adjust the pH of the hydrolyzate to 6, heat to 65°C, and pass through a 100-mesh sieve to obtain a brown-yellow transparent solution;

[0027] (2) Weigh 38.9kg of ferric chloride and dissolve it with 80kg of purified water and add it to the reaction tank, then add the prepared dextran 20 hydrolyzate, adjust the pH to 10 with 10mol / L sodium hydroxide solution, and control the pressure to 0.05MPa , the solution was heated to boiling, boiled for 1 hour, and then cooled to 35°C to obtain the complex solution; then technical means 1 was used for treatment, that is...

Embodiment 3

[0029] Embodiment 3: a kind of preparation method of iron dextran comprises the steps:

[0030] (1) Put 160kg of purified water into the reaction tank, control the pressure to 0.15MPa, stir and heat to 85°C, then add 60kg of dextran 20, boil until completely dissolved; add 5.4mol / L hydrochloric acid to adjust the pH of the solution to 5, continue Boil for 2 hours, then cool to 40°C, add 10mol / L sodium hydroxide solution to adjust the pH of the hydrolyzate to 7, heat to 75°C, and pass through a 100-mesh sieve to obtain a brown-yellow transparent solution;

[0031] (2) Weigh 38.9kg of ferric chloride and dissolve it with 90kg of purified water, add it to the reaction tank, then add the prepared dextran 20 hydrolyzate, adjust the pH to 11 with 10mol / L sodium hydroxide solution, and control the pressure to 0.15MPa , the solution was heated to boiling, boiled for 2 hours, and then cooled to 40°C to obtain the complex solution; then technical means 1 was used for processing, that is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com