Nano-silver electrically conductive printing ink and preparation method thereof

A technology of conductive ink and nano-silver, applied in inks, household appliances, applications, etc., can solve the problems of high cost and high amount of precious metal silver, and achieve the effects of low cost, simple preparation method and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

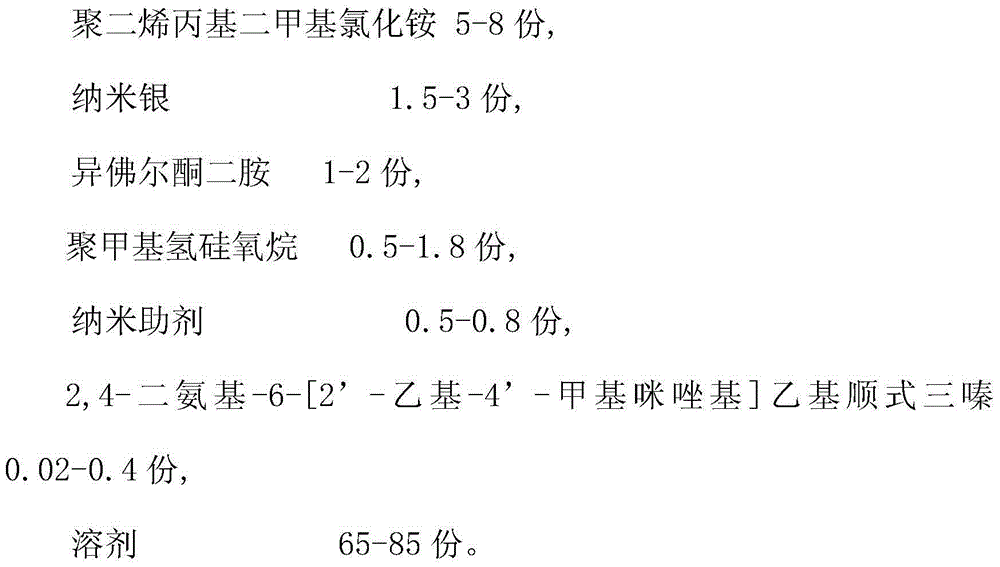

[0022] (1) 5 kg of polydiallyl dimethyl ammonium chloride, 1 kg of isophorone diamine, 0.5 kg of polymethylhydrogen siloxane and 0.5 kg of titanium dioxide nanoparticles are stirred evenly in a disperser;

[0023] (2) Add 1.5kg of nano-silver rods ground by a three-roll machine, 2,4-diamino-6-[2'-ethyl-4'-methylimidazolyl]ethyl cis-triazine 0.02kg and ethanol 65kg of mixed solution;

[0024] (3) Keeping the temperature at 95° C. for 1 hour to obtain the nano-silver conductive ink.

Embodiment 2

[0026] (1) 5kg of polydiallyldimethylammonium chloride, 2kg of isophoronediamine, 0.5kg of polymethylhydrogensiloxane and 0.5kg of titanium dioxide nanoparticles are stirred in a disperser;

[0027] (2) Add 3 kg of nano-silver balls ground by a three-roll machine, 2,4-diamino-6-[2'-ethyl-4'-methylimidazolyl] ethyl cis-triazine 0.4 kg and isopropyl A mixed solution of alcohol 85kg;

[0028] (3) Keeping the temperature at 95° C. for 1 hour to obtain the nano-silver conductive ink.

Embodiment 3

[0030] (1) 8 kg of polydiallyl dimethyl ammonium chloride, 2 kg of isophorone diamine, 1.8 kg of polymethyl hydrogen siloxane and 0.8 kg of graphene nanosheets are stirred in a disperser;

[0031] (2) Add 3kg of nano-silver balls ground by a three-roll machine, 2,4-diamino-6-[2'-ethyl-4'-methylimidazolyl]ethyl cis-triazine 0.4kg and propylene glycol 85kg mixed solution;

[0032] (3) heat preservation at 105° C. for 2 hours to obtain nano-silver conductive ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com