Three-coordination dual-core copper iodide complex light-emitting material

A technology of light-emitting material and cuprous iodide, applied in the direction of light-emitting materials, copper organic compounds, compounds of elements of Group 5/15 of the periodic table, etc. and other problems, to achieve the effect of low production cost, good phosphorescence emission performance, and cheap purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Preparation of a large number of microcrystalline samples: weigh 60mg of CuI and dissolve it in 20mL of acetonitrile, weigh 110mg of o-anisyl 3 The P ligand was dissolved in 20 mL of acetonitrile (the molar ratio of the three reactants was 1:1), the two solutions were mixed and stirred to make the coordination reaction fully occur, and finally the obtained yellow reaction liquid was removed by rotary evaporation. All the solvents were vacuum-dried to obtain a yellow crystal powder as the product with a yield of 99% (calculated as Cu).

Embodiment 2

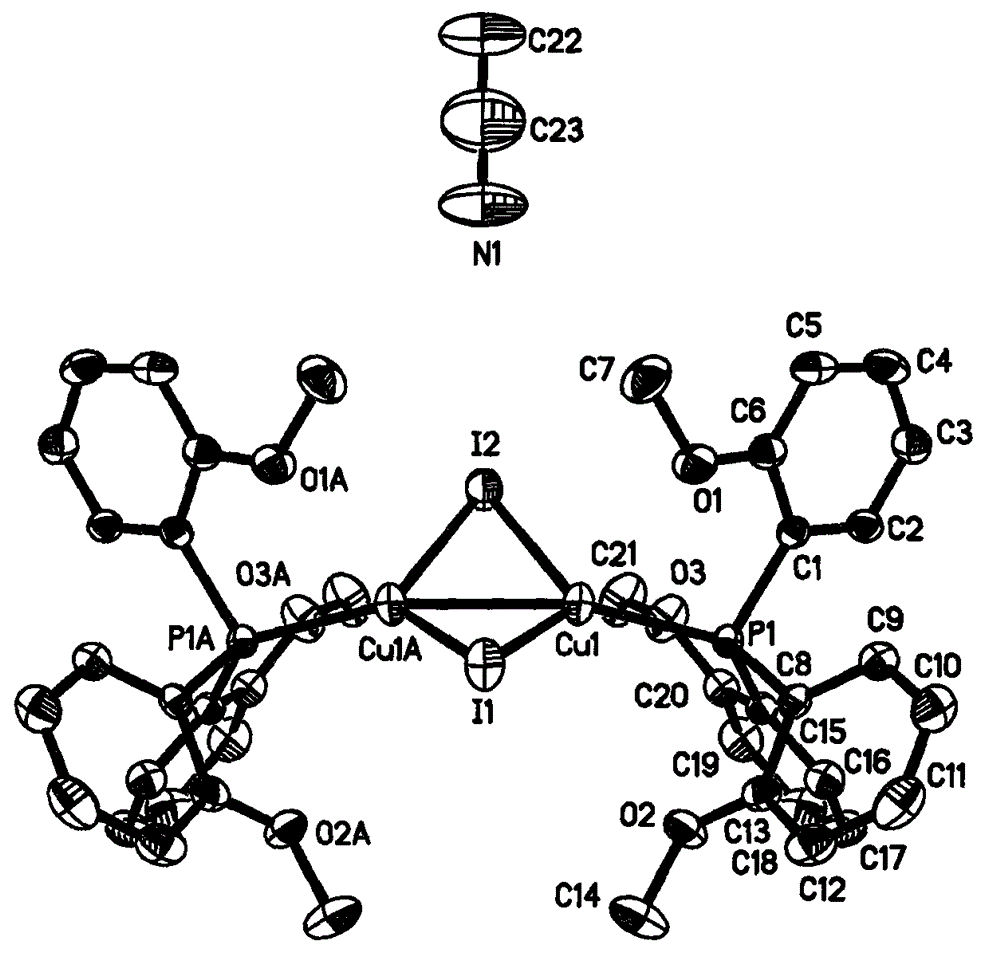

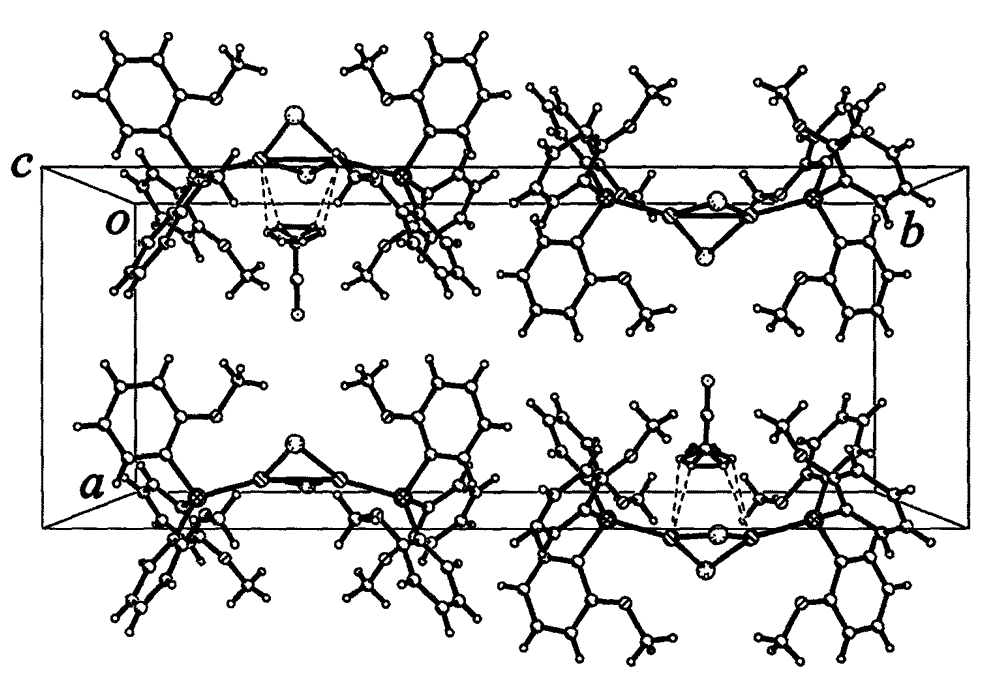

[0030] Synthesis of Dinuclear Cuprous Iodide Cluster Complex [CuI(o-anisyl 3 P)] 2 ·(CH 3 CN) single crystal: after weighing 19mg CuI and dissolving it in 50mL acetonitrile, then 36mg of o-anisyl 3 P ligand was added to the above solution at one time, stirred to dissolve it completely, and then filtered, and the filtrate was covered with isopropanol to promote the crystallization of the product, and a large number of yellow blocky crystals were precipitated after standing for several days. A yellow bulk transparent crystal with a size of 0.26mm×0.23mm×0.18mm was selected for X-ray single crystal diffraction structure test. The molecular structure of the compound is shown in the attached figure 1 , and its unit cell packing structure is shown in the attached figure 2 .

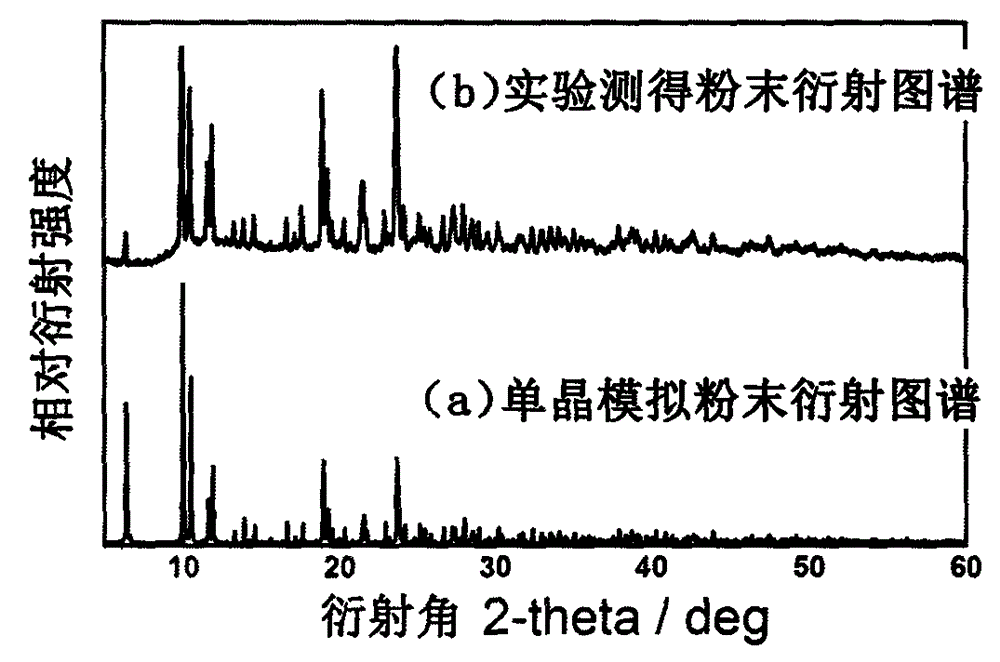

[0031] The dinuclear cuprous iodide cluster complex [CuI(o-anisyl 3 P)] 2 ·(CH 3 CN) a series of performance tests were carried out on pure phase crystal samples. The steady-state fluorescence test wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com