Biogas desulfurization device

A biogas desulfurization and biogas technology, which is applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of low hydrogen sulfide removal rate and large usage of chemical desulfurizers, reduce labor costs and mechanical costs, and overcome reliable operation. Low sexual performance, overcoming the effect of high usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

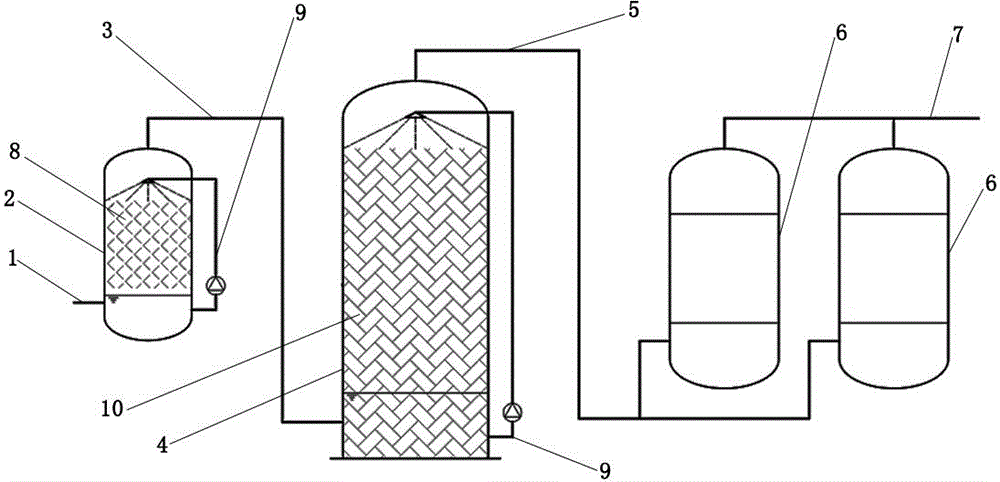

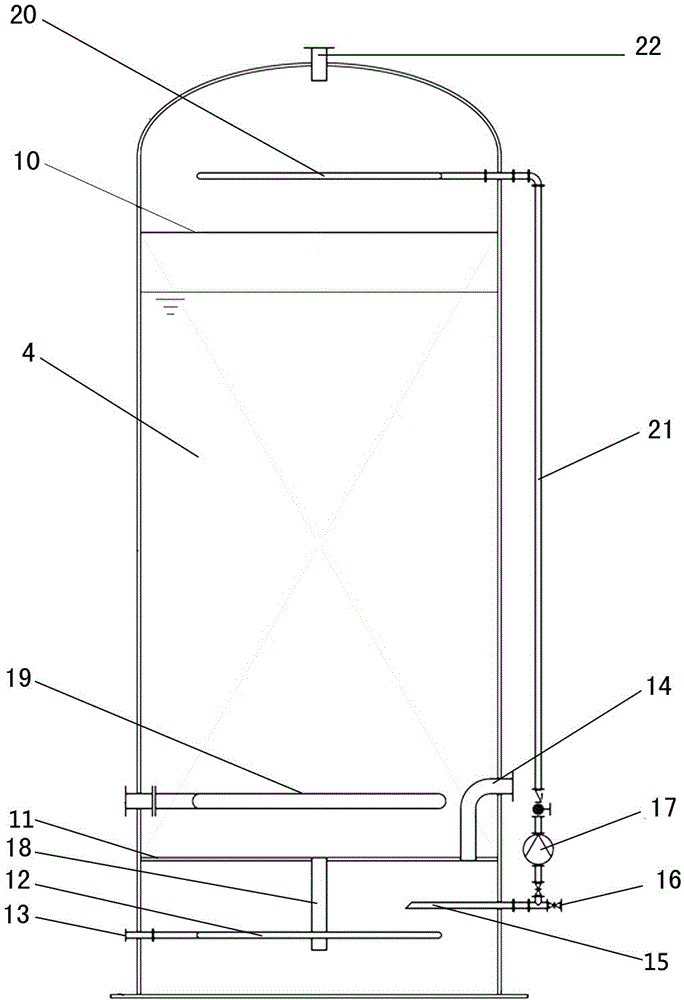

[0020] The biogas desulfurization device in this example is as figure 1 and figure 2 As shown, the side of the water washing tank 2 is provided with an air intake pipeline 1, and the top of the water washing tank 2 is provided with a water washing tank gas pipeline 3. The water washing tank gas pipeline 3 communicates with the bottom of the biological desulfurization tank 4, and the top of the biological desulfurization tank 4 A biological desulfurization tank gas pipeline 5 is provided, and the biological desulfurization tank gas pipeline 5 communicates with the bottom of the fine desulfurization tank 6, and the top of the fine desulfurization tank 6 is provided with a gas outlet pipeline 7, and two or more fine desulfurization tanks 6 are arranged in parallel; The water washing tank 2 and the biological desulfurization tank 4 are provided with a circulating spray device 9 ; the water washing tank 2 is provided with a multi-layer water spray packing layer 8 , and the biologi...

Embodiment 2

[0025] The biogas desulfurization device in this example is as figure 1 and image 3 As shown, except that in the biological desulfurization tank 4, a filler fluidization section 23 is arranged above the biofilm-adhered filler layer 10, and a desulfurization liquid distributor 20 is arranged above the filler fluidization section 23, the rest is the same as that of the first embodiment. .

[0026] In this example, when the total gas flow rate increases and exceeds the critical flow rate of the biofilm-attached filler, the biofilm-attached filler layer 10 in the biological desulfurization tank 4 can be fluidized, and a huge active biofilm surface is released, The hydrogen sulfide and the desulfurization liquid rich in dissolved oxygen have sufficient contact mass transfer and biochemical reaction on the active biofilm of the filler, so that the hydrogen sulfide is removed from the biogas. The biogas flow rate can be effectively increased, and the processing efficiency per unit...

Embodiment 3

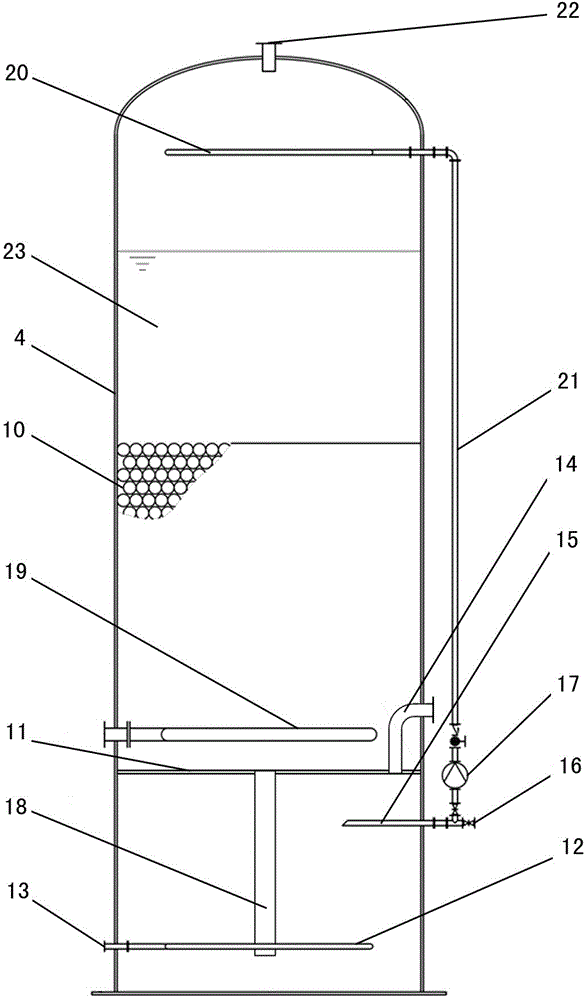

[0028] The biogas desulfurization device in this example is as figure 1 and Figure 4 As shown, the desulfurization liquid distributor 20 in the biological desulfurization tank 4 is a spiral tube that runs through the biofilm-attached filler layer 10 and the filler fluidization zone 23, and different spray pipe openings are set at different heights Compare. All the other are with embodiment two.

[0029]In this example, according to the change of the dissolved oxygen concentration gradient in the liquid phase when spraying is not performed, different spray pipe opening ratios are set at different heights of the desulfurization liquid distributor 20, so that the desulfurization liquid spray volume can be adjusted according to the dissolved oxygen concentration gradient. The change of the oxygen concentration gradient is timely and effectively supplemented, so as to achieve the purpose of eliminating the dissolved oxygen concentration gradient. It can also make the desulfuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com