Electrical steel annealing and heating support method

A supporting method and technology of electrical steel, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve problems such as surface damage of annealed steel strips, achieve high grades, reduce damage or nodules, and achieve high magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

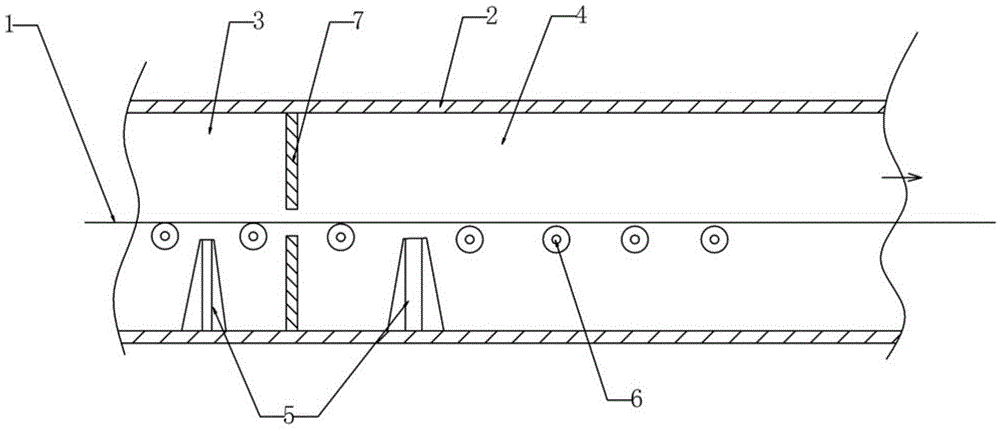

[0033] see figure 1 , the cold-rolled steel strip is heated to the annealing temperature between the heating section 3 and the soaking section 4 in the continuous annealing furnace for silicon steel, and is kept for a certain period of time before entering the subsequent cooling section, and then reaches room temperature after cooling. The length of the steel strip in the horizontal annealing furnace is very long, and under the fixing of the entrance and exit support rollers 6, the steel strip in the horizontal state will sag due to the effect of gravity. The amount of sag is related to the distance, tension and weight of the two support points. Use the plasma jet levitation device as a support to reduce the overhang of the strip. The number of plasma jet levitation devices is set according to the length of the furnace, the flow rate and pressure of the gas generated by the plasma jet levitation device, and the required droop.

Embodiment 2

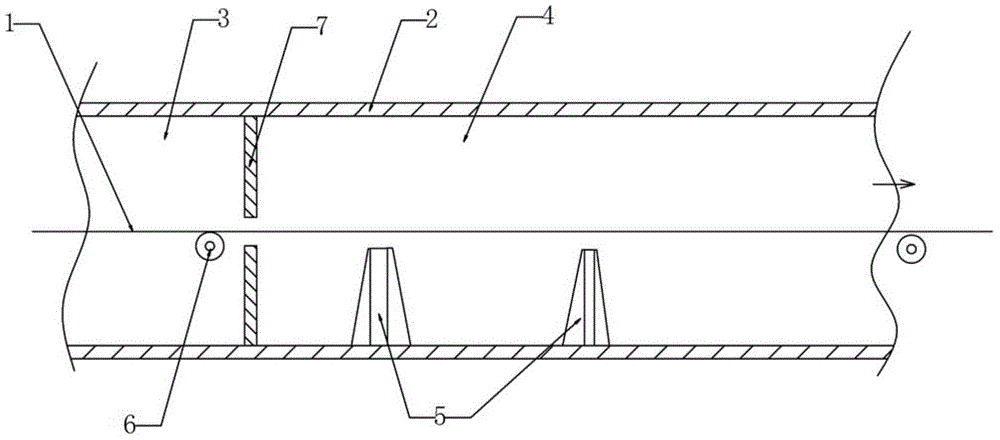

[0039] see figure 2 , the cold-rolled steel strip is heated to the annealing temperature between the heating section 3 and the soaking section 4 in the continuous annealing furnace for silicon steel, and is kept for a certain period of time before entering the subsequent cooling section, and then reaches room temperature after cooling. The length of steel band in horizontal annealing furnace is very long, and support roll 6 is installed in entrance, middle and outlet, and the steel band of horizontal state between support roll 6 will sag due to the effect of gravity. Simultaneously steel belt weight is when steel belt sags, forms certain pressure to support roller 6. The size of the pressure on the back-up rolls 6 is related to the thickness of the steel strip, the distance between the back-up rolls 6, and the tension. The plasma jet suspension device is used as an auxiliary support to reduce the hanging amount of the strip and reduce the pressure on the support roller 6. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com