Delustering high-strength viscose fiber and preparation method and application thereof

A viscose fiber, high-strength technology, applied in the field of textile fiber processing, can solve problems such as high cost, and achieve the effects of improving brittleness, increasing elongation, and high strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

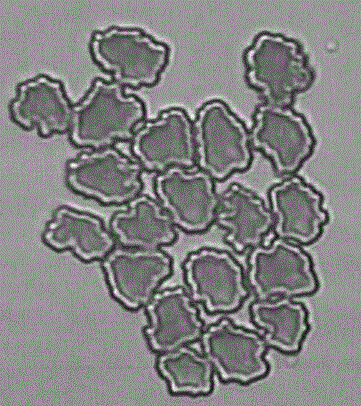

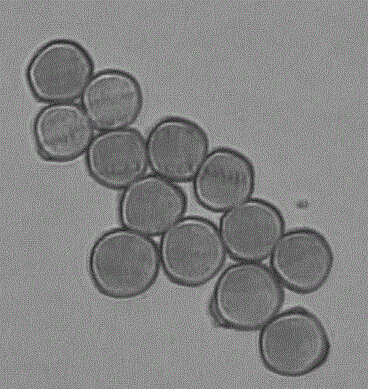

Image

Examples

Embodiment 1

[0096] The high-strength viscose fiber involved in this embodiment is made of pulp raw materials with a polymerization degree of 650 to 1200, which are sequentially impregnated, ground, crushed, kneaded, depolymerized, yellowed, dissolved, filtered, defoamed, matured, spun Obtained after silk drawing and post-treatment, the high-strength viscose fiber meets:

[0097] Dry breaking strength ≥ 3.15 cN / dtex;

[0098] Wet breaking strength ≥ 1.70cN / dtex;

[0099]The strength required to produce 5% elongation in wet state is ≥0.55cN / dtex,

[0100] Dry elongation at break 15.0~19.0%;

[0101] Wet elongation at break 16.0~21.0%;

[0102] Crystallinity 40.0~45.0%;

[0103] The radial water swelling degree is 22-26%;

[0104] The content of matting agent is 0.8-5%.

Embodiment 2

[0106] The difference between this embodiment and embodiment 1 is: the high-strength viscose fiber involved in this embodiment also satisfies:

[0107] Whiteness ≥ 85%;

[0108] Linear density deviation rate≤±2.0%;

[0109] Residual sulfur≤7.0mg / 100g;

[0110] Length deviation rate≤±3.0%;

[0111] Ultra-long fiber rate ≤ 0.5%;

[0112] Double-length fiber≤1.0mg / 100g;

[0113] Defect ≤ 1.0mg / 100g.

Embodiment 3

[0115] A kind of preparation method of matting type high-strength viscose fiber, the steps are as follows:

[0116] A. Put the pulp raw material with a degree of polymerization of 650 on the feeder pulp first, set the feeding speed to 40kg / min, then put the raw material into the dipping tank, and grind it with a grinder to make a pulp with a concentration of 3%. Porridge, wherein the purpose of grinding is to open and disperse the fibers through mechanical action, thereby increasing the alkalization speed and alkalization rate of cellulose;

[0117] B. Send the pulp porridge prepared in step A to a press machine, and then send it to a pulverizer for crushing to obtain alkali cellulose, send the alkali cellulose to a kneading machine, and obtain a pulp porridge with a concentration of 30% after processing , in this step, the press can remove the excess lye, and the excess lye can be recycled. The treatment method is to use a filter with a filter screen of 60 mesh and a vacuum o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pulverization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com