Patents

Literature

30results about How to "Appropriate water absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degradable polyethylene modified material and preparation method thereof

The invention relates to a degradable polyethylene modified material and a preparation method thereof. The degradable polyethylene modified material is mainly applied to the production of a disposable degradable plastic bag and is mainly prepared from high-density polyethylene, calcium carbonate, konjac glucomannan, corn starch and a foaming agent. Due to the water retentivity of the konjac glucomannan, the disposable degradable plastic bag prepared from the degradable polyethylene modified material can be maintained in a relative drying state, so that the deterioration and the smelliness of food wastes contained in the disposable degradable plastic bag are difficult to occur. Meanwhile, the disposable degradable plastic bag has stronger toughness due to the addition of the konjac glucomannan, so that the disposable degradable plastic bag is difficult to break. The disposable degradable plastic bag is easy to degrade by taking the konjac glucomannan as a raw material, so that the environment pollution is avoided. The plastic bag commonly used in the existing market is prepared from a single plastic polymer, so that character writing or printing on the plastic bag cannot be carried out. The disposable degradable plastic bag provided by the invention is molded in a blowing manner by using a foaming technique, so that the character writing or the pattern printing on the disposable degradable plastic bag can be carried out.

Owner:江西缘至家实业有限公司

Semi-dull high-strength low-elongation viscose fiber as well as preparation method and application thereof

InactiveCN104846458AGood skin affinityHigh strengthArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceSpinning

The invention provides a semi-dull high-strength low-elongation viscose fiber as well as a preparation method and application thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, directional polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has an index system that the dry fracture strength is more than or equal to 3.20cN / dtex, the wet fracture strength is more than or equal to 1.70cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.6cN / dtex, the dry elongation at break is 13.0-16%, and the wet elongation at break is 16.0-21.0%. The semi-dull high-strength viscose fiber provided by the invention is prepared by virtue of technical innovation, and is a novel fiber variety which has an index system different from that of ordinary viscose fibers and Modal fibers, and a product of the fiber shows high and strong fiber characteristics and also shows skin affinity stronger than that of cotton fibers, so that the semi-dull high-strength low-elongation viscose fiber can effectively replace the existing differentiation viscose fiber, the development and the industrial upgrading of downstream novel textiles can be promoted while the processability of the downstream process of the viscose fiber is improved, and the semi-dull high-strength low-elongation viscose fiber can be well applied to the field of producing underclothes and high-grade woven fabrics.

Owner:YIBIN GRACE GROUP CO LTD +2

High-strength low-elongation viscose and preparing method thereof

InactiveCN104831392AHigh water absorption characteristicsGood skin affinityArtificial filament washing/dryingArtificial filaments from viscoseBreaking strengthIndex system

The invention discloses high-strength low-elongation viscose and a preparing method thereof. The high-strength low-elongation viscose is made by subjecting pulp material orderly to soaking, grinding, pressing and crushing, rubbing, accumulation reducing, yellowing, dissolving, filtering, defoaming, curing, spin-drawing and post-processing. The high-strength low-elongation viscose has dry break strength not less than 3.10 cN / dtex and wet break strength not less than 1.60cN / dtex, requires strength not less than 0.55cN / dtex at 5% of elongation in the wet state and has the dry elongation at break being 11.0% to 19.0%. The high-strength low-elongation viscose is a novel fiber made by technical innovation, has an index system different from the common viscose and the modal fiber, has the high strength and low elongation features of the modal fibers, has higher skin affinity than cotton fiber and effectively replaces the existing differential viscose, downstream processability of the viscose is improved, and the development and industrial update of the downstream novel textiles is promoted.

Owner:YIBIN GRACE GROUP CO LTD +2

Preparation method for hydrocolloid dressing for promoting wound repairing

ActiveCN106310361AReduce the number of replacementsPromote healingAbsorbent padsBandagesCross-linkFiber

The invention discloses a preparation method for hydrocolloid dressing for promoting wound repairing, belonging to the technical field of medical dressing preparation. The method comprises the following steps: adding AFGF freeze-dried powder into a mixed solution of gelatin and carboxymethyl chitosan, thereby acquiring an AFGF-loaded transparent fluid; mixing with dissolving fluid of the matters including sodium carboxymethylcellulose, apple pectin, and the like; ultrasonically oscillating and then adding a cross-linking agent; performing cross-linking reaction under a certain temperature, acquiring reaction fluid and then mixing with resin viscous fluid, thereby acquiring a spinning solution; spinning by adopting a wet method, thereby acquiring an AFGF-loaded fiber; mixing with a pure cotton fiber and spinning to form cloth. According to the preparation method, the apple pectin is added, so that the water absorption lasting time of the dressing is increased and the gelling is quickened; styrene-isoprene segmented copolymer is added, so that the dressing viscidity and the peeling strength are effectively improved; hydrocolloid is prepared into weaved cloth and no film substrate is required, so that the problem of weak binding force between hydrocolloid and polymer film is solved and the wound repairing can be effectively promoted; the preparation method has wide application prospect.

Owner:青岛华元精细生物制品有限公司

Superfine viscose fiber and preparation method thereof

ActiveCN104846453AHigh water absorption characteristicsHigh water absorption propertiesArtificial thread manufacturing machinesArtificial filaments from viscoseFiber typeViscose

The invention discloses a superfine viscose fiber and a preparation method thereof. The superfine viscose fiber is prepared by using a pulp material sequentially through impregnation, grinding, pressing and crushing, kneading, pure oxygen reduced polymerization, xanthation, dissolution, filtration, defoaming, ripening, spinning and drawing and post-treatment. The viscose fiber satisfies conditions that the fineness is 0.88 to 1.11D, the dry fracture strength is higher than or equal to 3.20cN / dtex and the wet fracture strength is higher than or equal to 1.60cN / dtex. The high-tenacity low-elongation viscose fiber disclosed by the invention is a novel fiber type realized through technical innovation and has an indicator system different from common viscose fibers and modal fibers, products made by the viscose fibers not only reflect fiber characteristics of high tenacity and low elongation of modal fibers, but also reflect better skin adaptability than cotton fibers, can effectively replace the existing differential viscose fibers and can promote the development and industrial upgrade of downstream novel textiles on the premise of improving the downstream processing performance of the viscose fibers.

Owner:YIBIN GRACE GROUP CO LTD +2

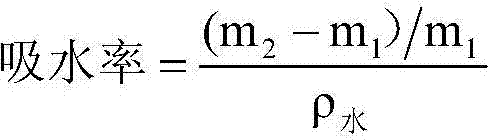

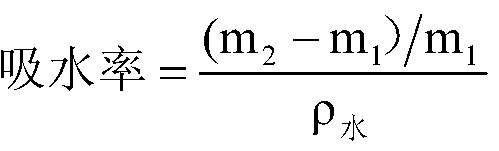

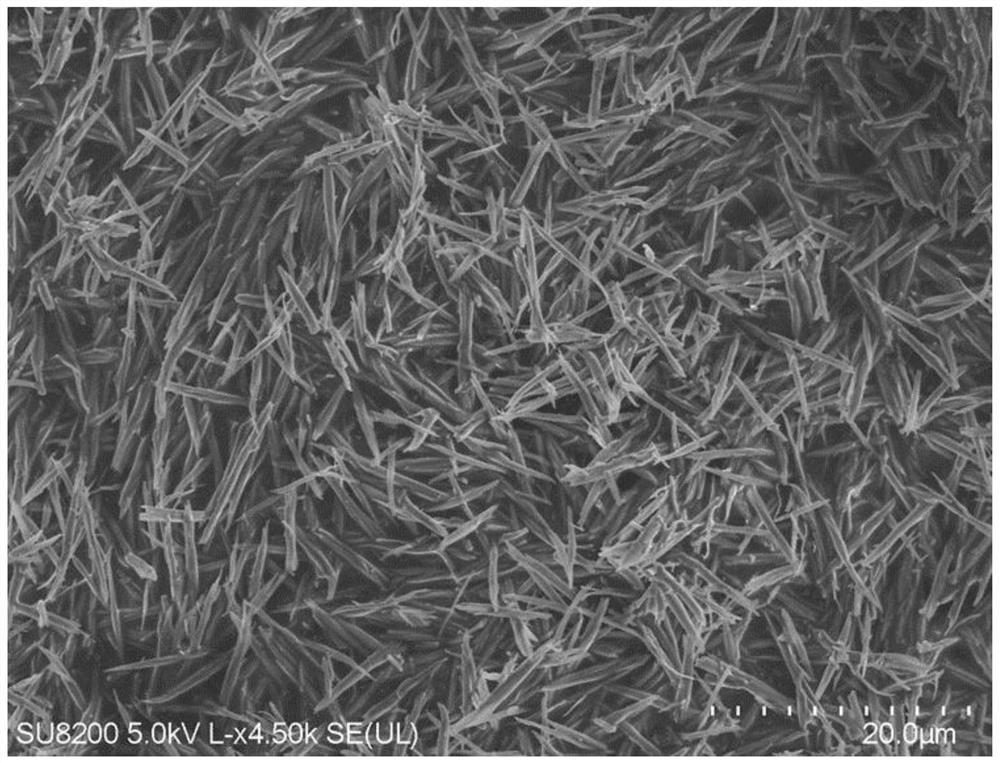

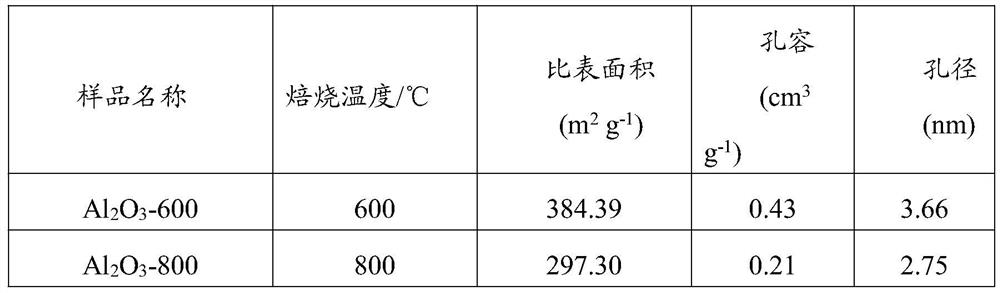

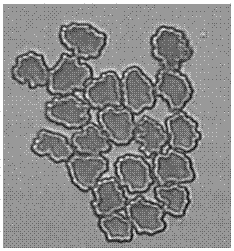

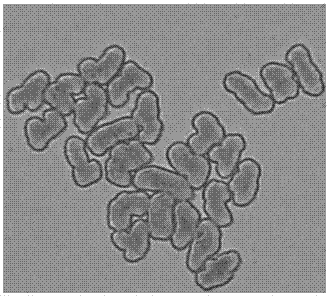

Rodlike alumina carrier preparation method and alumina carrier

ActiveCN110860281ASkeleton structure is stableEvenly distributedCatalyst carriersCatalyst activation/preparationAlkanePtru catalyst

The invention discloses a rodlike alumina carrier preparation method and an alumina carrier. The preparation method comprises the following steps: (1) uniformly mixing rodlike alumina powder with an extrusion aid; (2) uniformly mixing a peptizing agent and water, and uniformly spraying the mixture obtained in the step (1); and (3) molding the material obtained in the step (2), drying and roastingto obtain the final alumina carrier. The alumina carrier prepared by the method provided by the invention not only has a firm skeleton structure, but also can uniformly distribute active components inpores, that is, shows comprehensive properties such as high mechanical strength, proper water absorption rate and the like, and is especially suitable for being used as a carrier of an alkane dehydrogenation catalyst.

Owner:DALIAN UNIV OF TECH

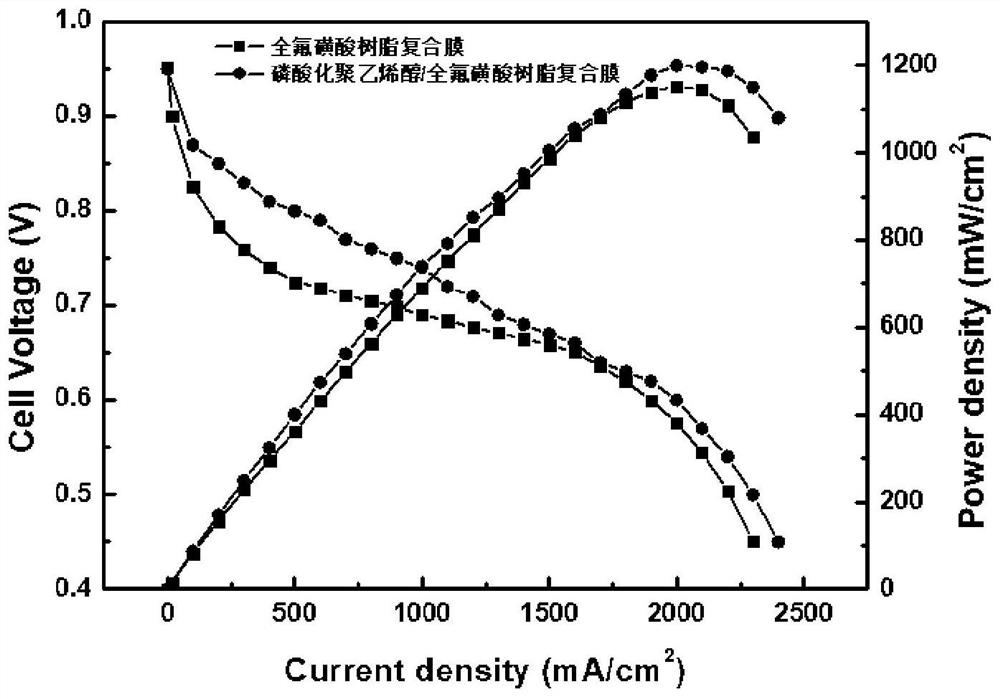

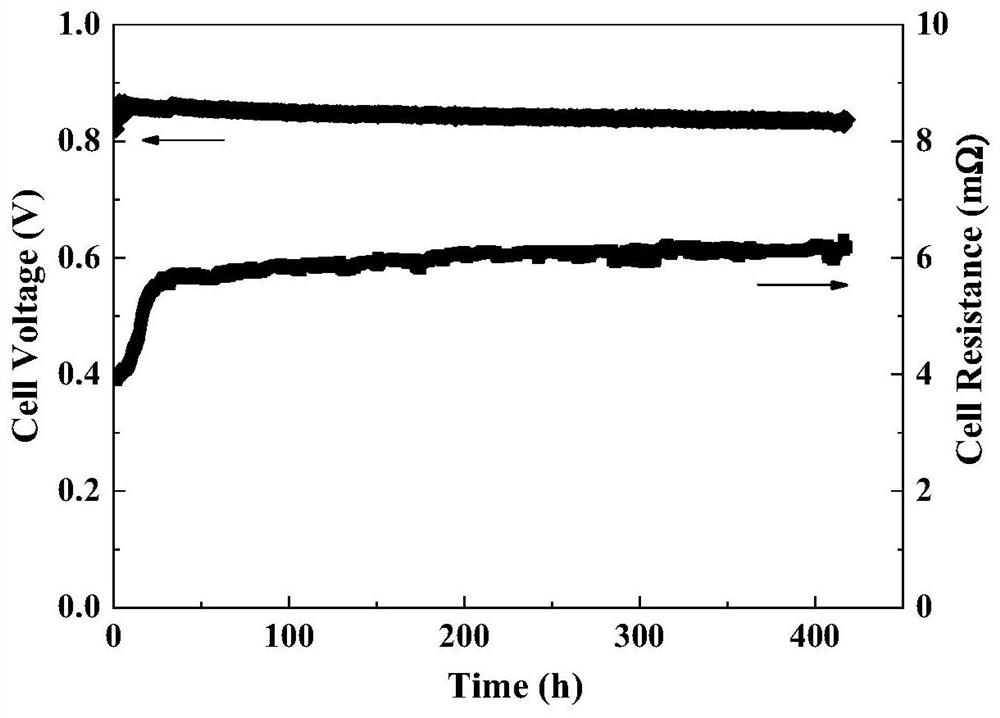

Phosphorylated polyvinyl alcohol/perfluorosulfonic acid resin compound and ion exchange membrane

ActiveCN113429715AImprove ionic conductivityImprove barrier propertiesFinal product manufactureFuel cellsPolymer sciencePolyvinyl alcohol

The invention discloses a phosphorylated polyvinyl alcohol / perfluorinated sulfonic acid resin compound. The compound comprises the following components in percentage by mass: 0.1 to 77 percent of phosphorylated polyvinyl alcohol and 23 to 99.9 percent of perfluorinated sulfonic acid resin, and is prepared by adopting a blending method. When the phosphorylated polyvinyl alcohol / perfluorosulfonic acid resin compound is used for preparing an ion exchange membrane, the swelling and water absorption of the composite membrane can be limited, the proton transmission energy barrier is reduced, and the proton transmission capability of the composite membrane under high-temperature and low-humidity conditions is improved; as a result, the composite membrane has high ionic conductivity, high barrier property, excellent physical and mechanical properties and proper water absorption, and the non-covalent bond cross-linked structure also enables the membrane material to maintain the characteristic of recycling.

Owner:国家电投集团氢能科技发展有限公司

Luminous high-strength low-elongation viscose and production method thereof

InactiveCN104831390AHigh water absorption characteristicsStrong skin affinityArtificial filament washing/dryingArtificial filaments from viscoseIndex systemFineness

The invention discloses a luminous high-strength low-elongation viscose and a production method thereof. The luminous high-strength low-elongation viscose is made by subjecting pulp material to soaking, grinding, press-crushing, rubbing, all-oxygen accumulation reducing, yellowing, dissolving, filtering, defoaming, curing, spin-drawing and post-processing; the luminous high-strength low-elongation viscose is 1.11D to 1.33D in fineness, not less than 3.10cN / dtex in dry break strength and not less than 1.60cN / dtex in wet break strength. The luminous high-strength low-elongation viscose is a novel fiber made by technical innovation, has an index system different from the common viscose and the modal fiber, has the high strength and low elongation features of the modal fiber, is higher in skin affinity than the cotton fiber and can effectively replace the existing differential viscose, downstream processability of the viscose is improved, and the development and industrial update of the downstream novel textiles can be promoted.

Owner:YIBIN GRACE GROUP CO LTD +2

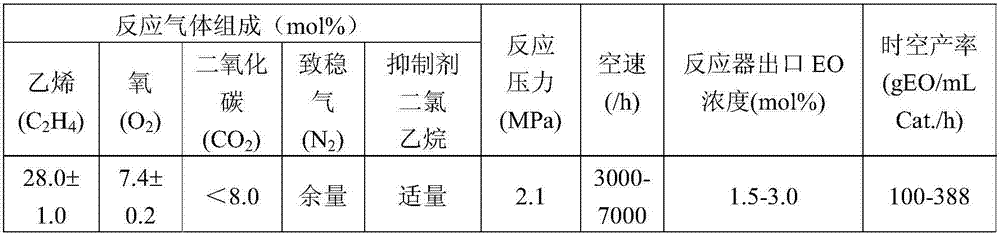

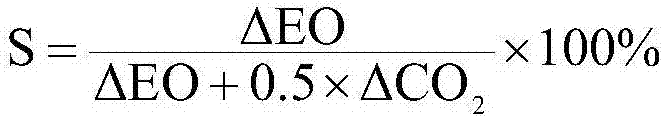

Alpha-alumina carrier used for silver catalyst, preparation method and application of same

ActiveCN107413389AGood dispersionImprove catalytic performanceCatalyst carriersOrganic chemistryAlkaline earth metalFluorine containing

The invention relates to an alpha-alumina carrier used for a silver catalyst and a preparation method thereof. The preparation method includes the steps of: uniformly mixing aluminum oxide trihydrate, pseudo-boehmite, a gallium-containing compound, a silicon-containing compound, a fluorine-containing compound and an alkaline earth metal compound to obtain a solid powder; adding a binder and water to prepare a mixture; and kneading, shaping, drying and roasting the mixture to obtain the alpha-alumina carrier. The invention also relates to the silver catalyst produced with the alpha-alumina carrier and an application of the catalyst for producing epoxy compounds through epoxidation of olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biodegradable hemostatic bone wax and preparation method thereof

InactiveCN109481726ADegradableExcellent physical sealing functionSurgical adhesivesPharmaceutical delivery mechanismWater bathsMass ratio

The invention provides biodegradable hemostatic bone wax. The preparative components are composed of acetic acid, glycerin and keratin, wherein a mass ratio of the acetic acid to glycerin to keratin is 1: (1-3): (8-10). The preparation method comprises the following steps: adding keratin into an acetic acid solution, and continuously stirring in a thermostatic water bath; and adding glycerin, anduniformly stirring and mixing. The hemostatic bone wax disclosed by the invention has degradability, excellent plugging performance and rapid hemostatic performance.

Owner:GUANGZHOU SUN SHING BIOTECH CO LTD

Semi-dull low-extensibility viscose fiber as well as preparation method and application thereof

InactiveCN104846456AGood air permeabilityImprove dye uptakeArtificial filament washing/dryingArtificial filaments from viscoseWoven fabricViscose fiber

The invention provides a semi-dull low-elongation viscose fiber as well as a preparation method and application thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, directional polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has an index system that the dry fracture strength is more than or equal to 3.10cN / dtex, the wet fracture strength is more than or equal to 1.60cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.55cN / dtex, the dry elongation at break is 12-14.5%, and the wet fracture extensibility is 16.0-21.0%. The semi-dull high-strength viscose fiber provided by the invention is prepared by virtue of technical innovation, is a novel fiber variety which has an index system different from that of ordinary viscose fibers and Modal fibers, shows high and strong fiber characteristics, and also shows skin affinity stronger than that of cotton fibers, so that the viscose fiber can effectively replace the existing differentiation viscose fiber, the development and the industrial upgrading of downstream novel textiles can be promoted while the processability of the downstream process of the viscose fiber is improved, and the semi-dull low-elongation viscose fiber can be well applied to the field of production of jean fabrics.

Owner:YIBIN GRACE GROUP CO LTD +2

Degradable polyethylene modified material and preparation method thereof

The invention relates to a degradable polyethylene modified material and a preparation method thereof. The degradable polyethylene modified material is mainly applied to the production of a disposable degradable plastic bag and is mainly prepared from high-density polyethylene, calcium carbonate, konjac glucomannan, corn starch and a foaming agent. Due to the water retentivity of the konjac glucomannan, the disposable degradable plastic bag prepared from the degradable polyethylene modified material can be maintained in a relative drying state, so that the deterioration and the smelliness of food wastes contained in the disposable degradable plastic bag are difficult to occur. Meanwhile, the disposable degradable plastic bag has stronger toughness due to the addition of the konjac glucomannan, so that the disposable degradable plastic bag is difficult to break. The disposable degradable plastic bag is easy to degrade by taking the konjac glucomannan as a raw material, so that the environment pollution is avoided. The plastic bag commonly used in the existing market is prepared from a single plastic polymer, so that character writing or printing on the plastic bag cannot be carried out. The disposable degradable plastic bag provided by the invention is molded in a blowing manner by using a foaming technique, so that the character writing or the pattern printing on the disposable degradable plastic bag can be carried out.

Owner:江西缘至家实业有限公司

High-tenacity and low-elongation viscose fibers, as well as preparation method and application thereof

ActiveCN104846455AHigh water absorption characteristicsGood skin affinityArtificial filament washing/dryingArtificial filaments from viscoseYarnIndex system

The invention discloses high-tenacity and low-elongation viscose fibers, as well as a preparation method and application thereof. The viscose fibers meet requirements of denier range of 0.80 to 1.50D, dry breaking tenacity of more than or equal to 3.20cN / dtex, wet breaking tenacity of more than or equal to 1.70cN / dtex, tenacity of more than or equal to 0.60cN / dtex required by the achievement of elongation of 5 percent in a wet state and dry breaking elongation of 13.0 to 16.0 percent, and is applied to the weaving of a high-twist fabric or a high-count yarn fabric. The high-tenacity and low-elongation viscose fibers belong to a novel fiber variety realized by technological innovation, have an index system different from those of ordinary viscose fibers and modal fibers, have the fiber characteristics of high tenacity and low elongation of the modal fibers and higher skin friendliness of cotton fibers, and can be effectively used instead of the conventional differentiated viscose fibers, the processability of a downstream procedure of the viscose fibers is improved, and in addition, the development and the industrial upgrading of a novel downstream textile can further be promoted.

Owner:YIBIN GRACE GROUP CO LTD +2

High-strength viscose fibers and preparation method and application of high-strength viscose fibers

ActiveCN104894670AStrong skin affinityHalf fiber lowArtificial filaments from viscoseMelt spinning methodsIndex systemYarn

The invention discloses high-strength viscose fibers and a preparation method and application of the high-strength viscose fibers. The high-strength viscose fibers meet the following requirements: the fineness range is between 0.80D and 1.50D, the dry breaking strength is more than or equal to 3.15cN / dtex, the wet breaking strength is more than or equal to 1.70cN / dtex, the strength needed by generation of 5% elongation in a wet state is more than or equal to 0.60cN / dtex, and the dry elongation at break is between 15.0% and 19.0%; the high-strength viscose fibers are suitable for spinning a high-twist fabric and a high-count yarn fabric. The high-strength viscose fibers achieved by technological innovation belong to a new type fiber variety and have an index system which is different from those of common viscose fibers and modal fibers. The high-strength viscose fibers have the characteristics of high strength and secondary low elongation of the modal fibers, also have the higher skin-touching performance than the cotton fibers, can be used for effectively replacing differentiation viscose fibers in the prior art, and can be used for promoting the development of downstream new style textiles and industry upgrade while improving the downstream working procedure processing performance.

Owner:YIBIN GRACE GROUP CO LTD +2

Alpha-aluminum oxide carrier, preparation method, and application thereof

ActiveCN107413388AGood dispersionImprove catalytic performanceCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsMass contentAluminium oxide

The invention relates to an alpha-aluminum oxide carrier, a preparation method, and an application thereof. During preparation of the carrier, a certain amount of a gallium-containing compound additive is added, wherein mass content of gallium in the carrier is 0.02-15.00%. The preparation method particularly includes the steps of: mixing aluminum oxide trihydrate, pseudo-boehmite, a gallium-containing compound and optionally alkaline-earth metal compounds and / or fluorides to prepare a solid mixture; adding a binder and water to the solid mixture to prepare an alpha-aluminum oxide precursor mixture; and kneading, shaping, drying and roasting the precursor mixture to finally obtain the alpha-aluminum oxide carrier. The catalyst carrier can be applied in olefin epoxidation reaction, selective hydrogenation of alkyne and diene, and methane reforming reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

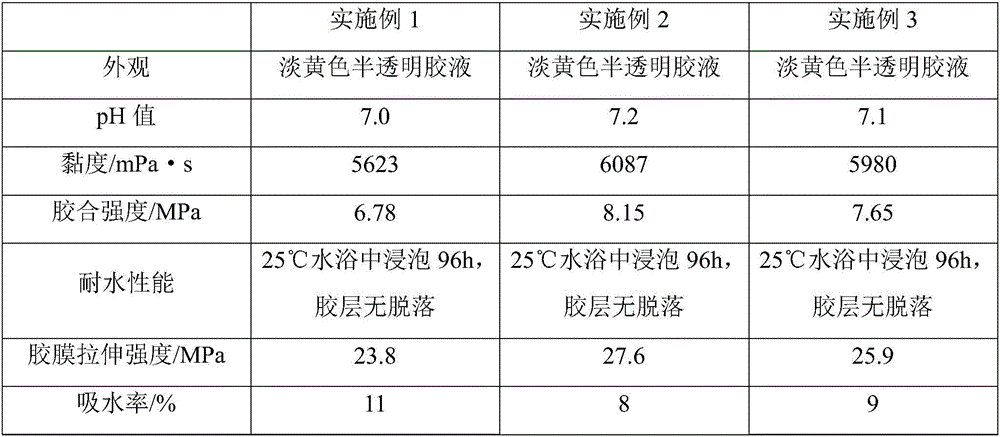

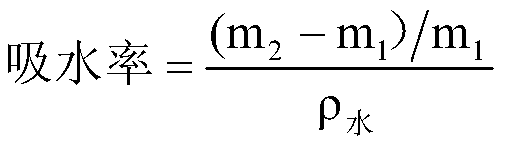

Metal bellows adhesive based on nano cellulose modification and preparation method thereof

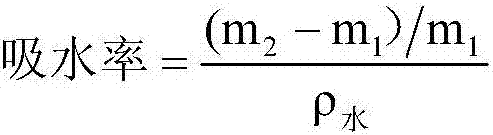

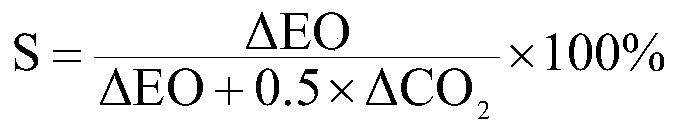

InactiveCN106543946AAppropriate water absorptionShort curing timeNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyvinyl alcohol

The invention discloses a metal bellows adhesive based on nano cellulose modification and a preparation method thereof. The metal bellows adhesive is prepared from the following components in parts by weight: 18-39 parts of polyurethane, 12-35 parts of epoxy resin, 11-25 parts of polyvinyl alcohol, 9-21 parts of polyvinyl chloride, 8-22 parts of nano cellulose MFC, 8-21 parts of magnesium sulfate, 8-23 parts of iron oxide, 5-14 parts of aluminum oxide and 11-20 parts of borax. The metal bellows adhesive disclosed by the invention has the advantages that firstly, the water absorption rate is appropriate, and the curing time of the adhesive is shortened; and secondly, the metal bellows adhesive based on nano cellulose modification weakens the brittleness of a pure resin adhesive and has good compatibility with a bonding medium.

Owner:WUXI YONGXING METAL HOSE

Semi-dull high-intensity low-elongation viscose fiber and preparing method thereof

ActiveCN104846460AGood skin affinityHigh strengthMonocomponent cellulose artificial filamentBleaching apparatusFiberPolymer science

The invention provides semi-dull high-intensity low-elongation viscose fiber and a preparing method of the semi-dull high-intensity low-elongation viscose fiber. The viscose fiber is obtained through sequentially carrying out soaking, grinding, pressing and crushing, kneading, polymerization reduction, yellowing, dissolution, filtering, defoaming, aging, spinning traction and post treatment on pulp raw materials. The viscose fiber has the following indexes that the fiber number is 1.11 to 1.67 dtex, the dry fracture intensity is greater than or equal to 3.10cN / dtex, the wet fracture intensity is higher than or equal to 1.60cN / dtex, the intensity required for generating the 5-percent elongation rate in the wet state is higher than or equal to 0.55N / dtex, and the dry fracture elongation rate is 11.0 to 19.0 percent. The high-intensity low-elongation viscose fiber related by the invention is a novel fiber variety realized through technical innovation, an index system is different from that of ordinary viscose fiber and modal fiber; a product shows the high-intensity and low-elongation fiber features of the modal fiber, and also shows the higher skin affinity than cotton fiber; the existing differentiated viscose fiber can be effectively replaced; the downstream work procedure processing performance of the viscose fiber is improved; meanwhile, the development and the industrial updating of downstream novel textiles can also be promoted.

Owner:YIBIN GRACE GROUP CO LTD +2

Delustering high-strength viscose fiber and preparation method and application thereof

InactiveCN104831393AImprove dye uptakeGuaranteed multiple responsesMonocomponent cellulose artificial filamentBleaching apparatusSocial benefitsBreaking strength

The invention discloses a delustering high-strength viscose fiber and a preparation method and application thereof. The delustering high-strength low-elongation viscose fiber is obtained by subjecting pulp materials to dipping, grinding, squeezing smashing, rubbing, depolymerizing, yellowing, dissolving, filtering, deaerating, ripening, spinning drawing and post-processing sequentially. The delustering high-strength viscose fiber meets the technical indexes that the dry breaking strength is not smaller than 3.15cN / dtex, the wet breaking strength is not smaller than 1.70cN / dtex, the strength for generating 5% of elongation in a wet condition is not smaller than 0.55cN / dtex, the dry breaking elongation is 15.0%-19.0%, the wet breaking elongation is 16.0%-21.0%, radial water swelling capacity is 22%-26%, and the content of a delustering agent is 0.8%-5%. The delustering high-strength viscose fiber is a novel viscose fiber, is lower than a modal fiber in production cost, has great economic benefit and social benefit, and is mainly applied to the field of dense siro-spinning.

Owner:YIBIN GRACE GROUP CO LTD +2

Ultrafine semi-dull high-strength low-elongation viscose fiber and preparation method thereof

ActiveCN104846462AGood skin affinityHigh strengthMonocomponent cellulose artificial filamentWet spinning methodsPolymer scienceSpinning

The invention provides an ultrafine semi-dull high-strength low-elongation viscose fiber and a preparation method thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has the following indexes that the fineness is 0.8-1.11dtex, the dry fracture strength is more than or equal to 3.10cN / dtex, the wet fracture strength is more than or equal to 1.60cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.55cN / dtex, and the dry elongation at break is 11.0-19.0%. The ultrafine high-strength low-elongation viscose fiber is a novel fiber variety realized by virtue of technical innovation, and has an index system which is different from that of ordinary viscose fibers and Modal fibers, and a product of the fiber shows the fiber characteristics of high strength and low elongation of the Modal fibers and also shows skin affinity stronger than that of cotton fibers, so that the ultrafine semi-dull high-strength low-elongation viscose fiber can effectively replace the existing differentiation viscose fiber, and while the processability of the downstream process of the viscose fiber is improved, the development and the industrial upgrading of downstream novel textiles are promoted.

Owner:YIBIN GRACE GROUP CO LTD +2

A semi-dull high-strength low-elongation viscose fiber and its preparation method

ActiveCN104846457BGood skin affinityHigh strengthArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceSpinning

The invention provides a semi-dull, high-strength, low-elongation viscose fiber and a preparation method thereof. The viscose fiber is prepared by impregnating pulp raw materials, grinding, crushing, kneading, depolymerizing, yellowing, dissolving, and filtering in sequence. , defoaming, ripening, spinning and drawing and post-treatment, the viscose fiber has the following indicators: dry breaking strength ≥ 3.10 cN / dtex, wet breaking strength ≥ 1.60 cN / dtex, 5% elongation in wet state The strength required for elongation is ≥0.55cN / dtex, and the dry elongation at break is 11.0-19.0%. The high-strength and low-elongation viscose fiber involved in the present invention is a new type of fiber achieved through technological innovation. It has an index system different from ordinary viscose fiber and modal fiber, and its products not only show the high-strength, low-elongation fiber characteristics of modal fiber , it also shows stronger skin-friendly properties than cotton fibers, which can effectively replace the existing differentiated viscose fibers. While improving the processing performance of viscose fibers in downstream processes, it can also promote the development and industrialization of downstream new textiles upgrade.

Owner:YIBIN GRACE GROUP CO LTD +2

α-alumina carrier for silver catalyst and its preparation method and application

ActiveCN107413389BGood dispersionImprove catalytic performanceCatalyst carriersOrganic chemistryAlkaline earth metalPtru catalyst

The invention relates to an alpha-alumina carrier used for a silver catalyst and a preparation method thereof. The preparation method includes the steps of: uniformly mixing aluminum oxide trihydrate, pseudo-boehmite, a gallium-containing compound, a silicon-containing compound, a fluorine-containing compound and an alkaline earth metal compound to obtain a solid powder; adding a binder and water to prepare a mixture; and kneading, shaping, drying and roasting the mixture to obtain the alpha-alumina carrier. The invention also relates to the silver catalyst produced with the alpha-alumina carrier and an application of the catalyst for producing epoxy compounds through epoxidation of olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of high-strength viscose fiber and its preparation method and application

ActiveCN104894670BHigh strengthSoft touchArtificial filaments from viscoseMelt spinning methodsFiberYarn

The invention discloses a high-strength viscose fiber and its preparation method and application. The viscose fiber satisfies the following requirements: the fineness range is between 0.80 and 1.50D, the dry breaking strength is ≥3.15 cN / dtex, and the wet breaking strength is ≥1.70cN / dtex, the strength required to produce 5% elongation in a wet state is ≥0.60cN / dtex, and the dry elongation at break is 15.0-19.0%, suitable for textile high-twist fabrics or high-count yarn fabrics. The high-strength viscose fiber involved in the present invention is a new type of fiber achieved through technological innovation. It has an index system different from ordinary viscose fiber and modal fiber. Its products not only show the fiber characteristics of high strength and low elongation of modal fiber, It also shows a stronger skin-friendly property than cotton fiber, which can effectively replace the existing differentiated viscose fiber. While improving the processing performance of viscose fiber in the downstream process, it can also promote the development of new downstream textiles and industrial upgrading .

Owner:YIBIN GRACE GROUP CO LTD +2

A kind of preparation method of rod-shaped alumina carrier and alumina carrier

ActiveCN110860281BSkeleton structure is stableEvenly distributedCatalyst carriersCatalyst activation/preparationAlkanePtru catalyst

A method for preparing a rod-shaped alumina carrier and an alumina carrier, comprising the following steps: (1) mixing rod-shaped alumina powder and an extrusion aid; ) on the obtained mixed material; (3) molding the material obtained in step (2), drying and roasting to obtain the final alumina carrier. The alumina carrier prepared by the method of the present invention not only has a relatively firm skeleton structure, but also can uniformly distribute the active components in the pores, that is, exhibits comprehensive properties such as high mechanical strength and suitable water absorption rate, and is especially suitable for use in As a carrier for alkane dehydrogenation catalysts.

Owner:DALIAN UNIV OF TECH

Semi-dull high-strength low-elongation viscose fiber and preparation method thereof

ActiveCN104846460BGood skin affinityHigh strengthMonocomponent cellulose artificial filamentWet spinning methodsBreaking strengthPolymer science

The invention provides a semi-dull, high-strength, low-elongation viscose fiber and a preparation method thereof. The viscose fiber is prepared by impregnating pulp raw materials, grinding, crushing, kneading, depolymerizing, yellowing, dissolving, and filtering in sequence. , defoaming, ripening, spinning and drawing, and post-treatment. The viscose fiber has the following indicators: fineness 1.11-1.67dtex, dry breaking strength ≥ 3.10 cN / dtex, wet breaking strength ≥ 1.60cN / dtex, The strength required to produce 5% elongation in wet state is ≥0.55cN / dtex, and the dry elongation at break is 11.0-19.0%. The high-strength and low-elongation viscose fiber involved in the present invention is a new type of fiber achieved through technological innovation. It has an index system different from ordinary viscose fiber and modal fiber, and its products not only show the high-strength, low-elongation fiber characteristics of modal fiber , it also shows stronger skin-friendly properties than cotton fibers, which can effectively replace the existing differentiated viscose fibers. While improving the processing performance of viscose fibers in downstream processes, it can also promote the development and industrialization of downstream new textiles upgrade.

Owner:YIBIN GRACE GROUP CO LTD +2

A kind of preparation method of promoting wound repair hydrocolloid dressing

ActiveCN106310361BReduce the number of replacementsPromote healingAbsorbent padsBandagesFiberCross-link

Owner:青岛华元精细生物制品有限公司

A kind of preparation method of regenerated ceramsite, regenerated ceramsite and application thereof

ActiveCN110922202BHigh strengthWith thermal insulationCeramic materials productionCeramicwareSludgeExpanded clay aggregate

The invention discloses a preparation method of a new type of regenerated ceramsite, a new type of regenerated ceramsite and its application. The preparation method of the new type of regenerated ceramsite uses sludge, iron tailings, and construction waste as raw materials to replace traditional clay, Shale has prepared a kind of recycled ceramsite. This preparation method uses iron tailings, sludge and construction waste to burn ceramsite. It can control the tailings and sludge problems, and can turn waste into treasure, input new materials for the building materials industry, increase the circular economic benefits of mines, and solve the problem of sludge treatment. It is an effective way for the comprehensive utilization of tailings and sludge, and The prepared new recycled ceramsite has low water absorption, high cylinder compressive strength, good frost resistance and firmness.

Owner:FUJIAN MINGNENG NEW BUILDING MATERIAL CO LTD

Ultra-fine semi-dull high-strength low-elongation viscose fiber and preparation method thereof

ActiveCN104846462BGood skin affinityHigh strengthMonocomponent cellulose artificial filamentWet spinning methodsPolymer scienceAfter treatment

The invention provides an ultrafine semi-dull high-strength low-elongation viscose fiber and a preparation method thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has the following indexes that the fineness is 0.8-1.11dtex, the dry fracture strength is more than or equal to 3.10cN / dtex, the wet fracture strength is more than or equal to 1.60cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.55cN / dtex, and the dry elongation at break is 11.0-19.0%. The ultrafine high-strength low-elongation viscose fiber is a novel fiber variety realized by virtue of technical innovation, and has an index system which is different from that of ordinary viscose fibers and Modal fibers, and a product of the fiber shows the fiber characteristics of high strength and low elongation of the Modal fibers and also shows skin affinity stronger than that of cotton fibers, so that the ultrafine semi-dull high-strength low-elongation viscose fiber can effectively replace the existing differentiation viscose fiber, and while the processability of the downstream process of the viscose fiber is improved, the development and the industrial upgrading of downstream novel textiles are promoted.

Owner:YIBIN GRACE GROUP CO LTD +2

A kind of α-alumina carrier and its preparation method and application

ActiveCN107413388BGood dispersionImprove catalytic performanceCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalPtru catalyst

The invention relates to an α-alumina carrier and its preparation method and application. In the present invention, a certain amount of gallium-containing compound additive is added during the preparation process of the carrier, and the mass content of gallium element in the carrier is 0.02%-15.00%. The specific preparation process is: mix alumina trihydrate, pseudo-boehmite, gallium-containing compounds and optional alkaline earth metal compounds and / or fluoride to obtain a solid mixture, add a binder and water to the solid mixture, An α-alumina precursor mixture is obtained, and the precursor mixture is kneaded, shaped, dried, and calcined to finally prepare an α-alumina carrier. The catalyst carrier prepared by the invention can be used in olefin epoxidation reaction, selective hydrogenation of alkynes and dienes, and methane reforming reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of superfine viscose fiber and preparation method thereof

ActiveCN104846453BHigh strengthLow elongationArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceDownstream processing

The invention discloses a superfine viscose fiber and a preparation method thereof. The superfine viscose fiber is prepared by using a pulp material sequentially through impregnation, grinding, pressing and crushing, kneading, pure oxygen reduced polymerization, xanthation, dissolution, filtration, defoaming, ripening, spinning and drawing and post-treatment. The viscose fiber satisfies conditions that the fineness is 0.88 to 1.11D, the dry fracture strength is higher than or equal to 3.20cN / dtex and the wet fracture strength is higher than or equal to 1.60cN / dtex. The high-tenacity low-elongation viscose fiber disclosed by the invention is a novel fiber type realized through technical innovation and has an indicator system different from common viscose fibers and modal fibers, products made by the viscose fibers not only reflect fiber characteristics of high tenacity and low elongation of modal fibers, but also reflect better skin adaptability than cotton fibers, can effectively replace the existing differential viscose fibers and can promote the development and industrial upgrade of downstream novel textiles on the premise of improving the downstream processing performance of the viscose fibers.

Owner:YIBIN GRACE GROUP CO LTD +2

A kind of high-strength low-elongation viscose fiber and its preparation method and application

ActiveCN104846455BHigh strengthSoft touchArtificial filament washing/dryingArtificial filaments from viscoseBreaking strengthYarn

The invention discloses a high-strength low-elongation viscose fiber and its preparation method and application. The viscose fiber satisfies: the fineness range is between 0.80 and 1.50D, the dry breaking strength is ≥3.20 cN / dtex, and the wet breaking strength is ≥ 1.70cN / dtex, the strength required to produce 5% elongation in wet state is ≥0.60cN / dtex, and the dry elongation at break is 13.0-16.0%, suitable for textile high-twisted fabrics or high-count yarn fabrics. The high-strength and low-elongation viscose fiber involved in the present invention is a new type of fiber achieved through technological innovation. It has an index system different from ordinary viscose fiber and modal fiber, and its products not only show the high-strength, low-elongation fiber characteristics of modal fiber , it also shows stronger skin-friendly properties than cotton fibers, which can effectively replace the existing differentiated viscose fibers. While improving the processing performance of viscose fibers in downstream processes, it can also promote the development and industrialization of downstream new textiles upgrade.

Owner:YIBIN GRACE GROUP CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com