Rodlike alumina carrier preparation method and alumina carrier

A technology of alumina carrier and alumina, which is applied in the direction of catalyst carrier, chemical instrument and method, catalyst activation/preparation, etc., to achieve the effect of suitable water absorption rate, firm skeleton structure and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of rod-shaped alumina

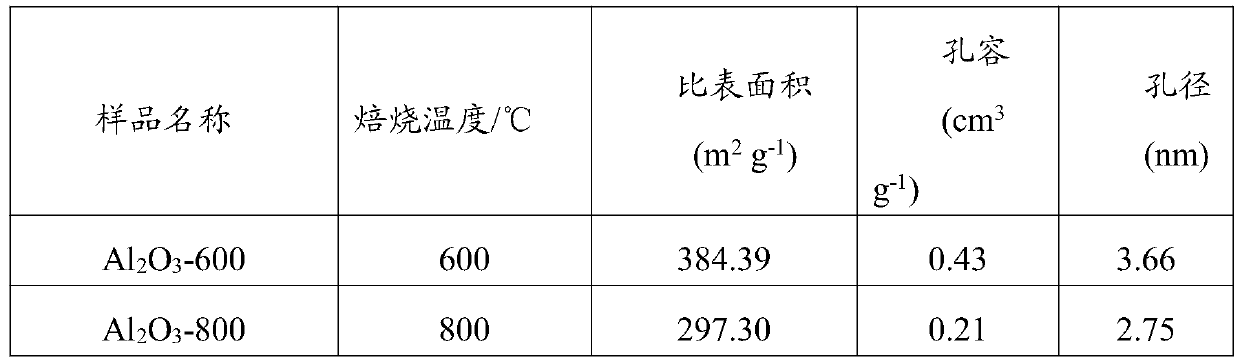

[0038] Measure 8400mL of deionized water and 1400mL of ethylene glycol into a 20L reactor, then weigh 2918.0g of aluminum nitrate nonahydrate and 2336.0g of urea and dissolve them completely in the above-mentioned mixed solution of water and ethylene glycol, and seal the reactor , set the rotation speed of the stirring paddle to 100rpm, the reaction temperature to 100°C, and the reaction time to 36h. After the reaction, the alumina precursor was obtained, filtered and washed with deionized water three times, washed once with absolute ethanol, and dried in an oven at 80°C for 24h. It is then fired in a muffle furnace for 2 hours to obtain the final rod-shaped alumina. The calcination temperature of the precursor and the texture parameters of the obtained rod-shaped alumina are given in Table 1.

[0039] Table 1 Precursor calcination temperature and structural parameters of rod-shaped alumina powder

[0040]

[0041] In the followi...

Embodiment 2

[0044] Weigh the prepared Al 2 o 3 -600g of rod-shaped alumina powder, 80.0g, mixed with 5.6g of scallop powder, stirred evenly (in a closed reaction kettle, the stirring speed of the stirring paddle was 70rpm, and stirred for 24h), and then the mixture of alumina and squat powder was put into kneading Mix 10min in the machine; Take by weighing concentrated nitric acid (concentration is 68wt%) 15.4g (it should be noted here that, the concentrated nitric acid that concentrated nitric acid concentration is in the scope of 65-68 mass % among the present invention all can be used in the present invention), dissolved Prepare a dilute nitric acid solution in 100g of deionized water, that is, the ratio of acid to powder is 0.18, and the ratio of water to powder is 1.17, and spray evenly into the mixed powder in the kneader; knead the above mixed material evenly, take it out after 60 minutes, and put it into the twin-screw extruder with a cylindrical orifice plate of Φ3.5 mm to obtai...

Embodiment 3

[0046] Adopt the same method as in Example 2 to prepare alumina moldings, the difference is that 5.6g of scallop powder and starch mixed extrusion aids are used, 14.6g of concentrated nitric acid is added, that is, the acid-powder ratio is 0.17, and the dried moldings Calcined at 700°C for 4 hours to obtain a molded product, denoted as A 2 . The radial compressive strength, water absorption, standard deviation and coefficient of variation of strength of the molded product obtained were measured, and the results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com