Preparation method of dimethyl sulfide

A technology of dimethyl sulfide and methanol, which is used in the preparation of sulfide, chemical instruments and methods, molecular sieve catalysts, etc., can solve the problems of low methanol conversion rate, and achieve stable skeleton structure, high conversion rate, and suitable acid center structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention provides a method for preparing dimethyl sulfide. The method includes: reacting hydrogen sulfide and methanol to produce dimethyl sulfide in the presence of a modified molecular sieve catalyst, characterized in that the modified The molecular sieve catalyst is prepared by first treating the molecular sieve catalyst with alkaline aqueous solution and then washing with acid solution.

[0017] According to the present invention, the modified treatment of the molecular sieve catalyst can be firstly treated with an alkaline aqueous solution, that is, the molecular sieve catalyst is placed in an alkaline aqueous solution environment, in a closed system, at a certain temperature for a period of time. Treating the molecular sieve catalyst with alkaline aqueous solution can improve the hydrothermal stability of the catalyst, thereby further improving the methanol conversion rate and the selectivity of dimethyl sulfide. Preferably, the alkaline aqueous solution...

Embodiment 1

[0049] This example is used to illustrate the preparation method of dimethyl sulfide of the present invention.

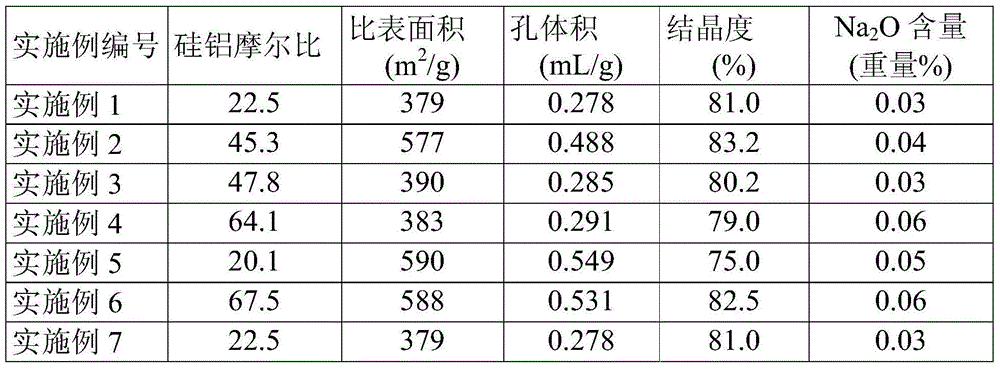

[0050] Add HZSM-5 molecular sieve (performance parameters as shown in Table 1) into a 2.0 wt% ammonia solution with a solid-to-liquid ratio of 1g molecular sieve: 10 mL ammonia solution, put it in a sealed reactor, and treat it at 80°C for 6 hours; then use 0.5 After washing with mol / L citric acid at 30℃ for 4 hours, the solid-to-liquid ratio of molecular sieve and citric acid solution is 1g molecular sieve: 5mL acid solution; after filtering, washing, drying, tableting, sieving, and taking 20-40 mesh The particles are packed in a tubular reaction tube with a diameter of 0.8 cm and a length of 55 cm. The volume of the catalyst particle bed is 2.0 cm. 3 .

[0051] The reaction temperature is 285℃, the reaction pressure is 1atm, the feed molar ratio of hydrogen sulfide and methanol is 1:2, and the total gas volumetric space velocity is 800h -1 Under the conditions, the cat...

Embodiment 2

[0053] This example is used to illustrate the preparation method of dimethyl sulfide of the present invention.

[0054] Add Hβ molecular sieve (performance parameters as shown in Table 1) into 3.0% by weight ammonia solution with a solid-to-liquid ratio of 1g molecular sieve: 18mL ammonia solution, put it in a sealed reactor and treat it at 100°C for 10h; then use 1.0mol / L tartaric acid was washed at 30°C for 5 hours, the solid-to-liquid ratio of molecular sieve and tartaric acid solution was 1g molecular sieve: 6mL acid solution; then filtered, washed, dried, compressed into tablets, sieved, and packed 20-40 mesh particles in diameter In a tubular reaction tube of 0.8cm and 55cm in length, the volume of the catalyst particle bed is 2.0cm 3 .

[0055] When the reaction temperature is 310℃, the reaction pressure is 1atm, the feed molar ratio of hydrogen sulfide and methanol is 1:2, and the total gas volumetric space velocity is 1000h -1 Under the conditions, the catalytic reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com