High-strength low-elongation viscose and preparing method thereof

A viscose fiber, high-strength and low-elongation technology is applied in the field of high-strength and low-elongation viscose fiber and its preparation, which can solve problems such as high cost and achieve the effects of improving brittleness, increasing fiber water absorption rate, and improving elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

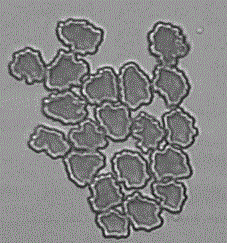

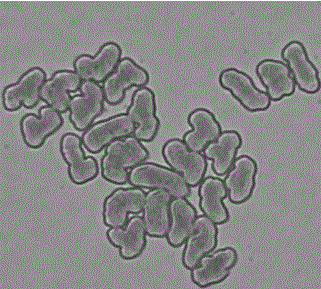

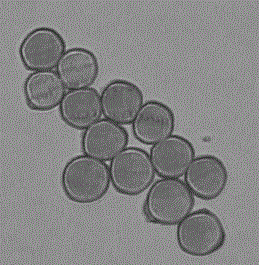

Image

Examples

Embodiment 1

[0094] The high-strength and low-extension viscose fiber involved in this embodiment is made of pulp raw material after dipping, grinding, squeezing and pulverizing, kneading, depolymerization, yellowing, dissolving, filtering, defoaming, aging, spinning drawing and post-treatment The obtained high-strength and low-stretch viscose fiber meets:

[0095] Dry breaking strength 3.10 cN / dtex, wet breaking strength 1.60 cN / dtex,

[0096] The strength required to produce 5% elongation in the wet state is 0.55cN / dtex,

[0097] Dry elongation at break 11.0%, wet elongation at break 16.0%,

[0098] 40% crystallinity, 22% radial water swelling degree,

[0099] Linear density deviation rate -4%, whiteness 83%,

[0100] Residual sulfur 8.0mg / 100g, length deviation rate +0.5%,

[0101] Super long fiber rate 0%, double long fiber 0mg / 100g,

[0102] Defects 0.5mg / 100g.

Embodiment 2

[0104] The difference between this embodiment and embodiment 1 is that the pulp raw material used in this embodiment is made by mixing cotton pulp, bamboo pulp, wood pulp, and hemp pulp with a mass ratio of 2:1:1:1. After testing, the viscose fiber prepared in this embodiment meets the product characteristics of high-strength and low elongation viscose fiber.

Embodiment 3

[0106] The difference between this embodiment and Embodiment 1 is that the pulp raw material used in this embodiment is made by mixing cotton pulp and bamboo pulp with a mass ratio of 2:1. After testing, the viscose fiber prepared in this embodiment meets the product characteristics of high-strength and low elongation viscose fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Pulverization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com