Metal bellows adhesive based on nano cellulose modification and preparation method thereof

A nanocellulose and metal bellows technology, applied in the field of material chemistry, can solve the problems of long curing time and inconvenient use, and achieve the effects of suitable water absorption, weakening brittleness and shortening curing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

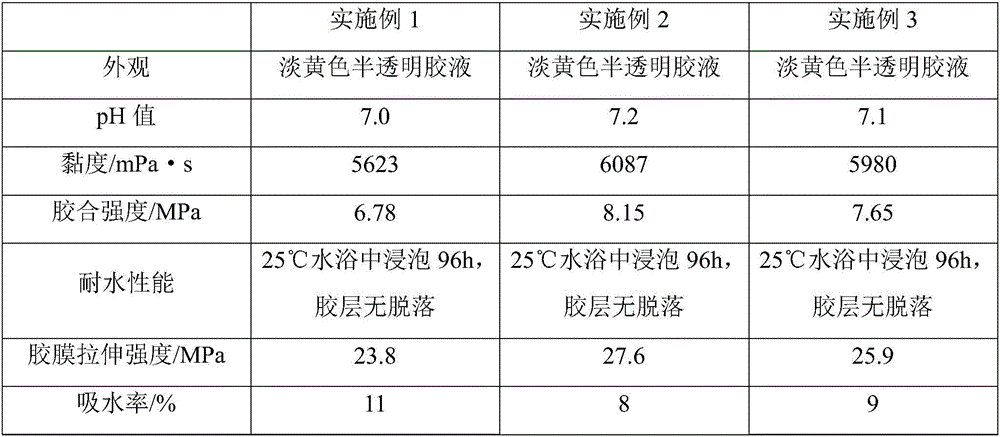

Embodiment 1

[0024] A metal bellows adhesive based on nanocellulose modification, which is made of the following components in proportion by weight: 18 parts of polyurethane, 12 parts of epoxy resin, 11 parts of polyvinyl alcohol, and 9 parts of polyvinyl chloride , 8 parts of nanocellulose MFC, 8 parts of magnesium sulfate, 8 parts of iron oxide, 5 parts of aluminum oxide, and 11 parts of borax.

[0025] A method for preparing a metal bellows adhesive based on nanocellulose modification, comprising the following steps:

[0026] (1) Adhesive matrix preparation: mix polyurethane and epoxy resin, add tetrahydrofuran to it, the total mass of the mixture: the volume of tetrahydrofuran is 1:2, stir and mix well, heat to 78°C, and stir while heating to obtain Adhesive matrix;

[0027] (2) Preparation of the first modifying agent: mix nanocellulose, magnesium sulfate, iron oxide and aluminum oxide, grind them into powder, add sulfuric acid solution with a mass fraction of 13% therein, and stir u...

Embodiment 2

[0033] A metal bellows adhesive based on nano-cellulose modification, which is made of the following components in proportion by weight: 32 parts of polyurethane, 28 parts of epoxy resin, 21 parts of polyvinyl alcohol, and 18 parts of polyvinyl chloride , 16 parts of nanocellulose MFC, 15 parts of magnesium sulfate, 17 parts of iron oxide, 9 parts of aluminum oxide, and 15 parts of borax.

[0034] A method for preparing a metal bellows adhesive based on nanocellulose modification, comprising the following steps:

[0035] (1) Adhesive matrix preparation: mix polyurethane and epoxy resin, add tetrahydrofuran to it, the total mass of the mixture: the volume of tetrahydrofuran is 1:4, stir and mix well, heat to 86°C, and stir while heating to obtain Adhesive matrix;

[0036] (2) Preparation of the first modifying agent: mix nanocellulose, magnesium sulfate, iron oxide and aluminum oxide, grind them into powder, add sulfuric acid solution with a mass fraction of 22% therein, and s...

Embodiment 3

[0042] A metal bellows adhesive based on nanocellulose modification, which is made of the following components in proportion by weight: 39 parts of polyurethane, 35 parts of epoxy resin, 25 parts of polyvinyl alcohol, and 21 parts of polyvinyl chloride , 22 parts of nanocellulose MFC, 21 parts of magnesium sulfate, 23 parts of iron oxide, 14 parts of aluminum oxide, and 20 parts of borax.

[0043]A method for preparing a metal bellows adhesive based on nanocellulose modification, comprising the following steps:

[0044] (1) Adhesive matrix preparation: mix polyurethane and epoxy resin, add tetrahydrofuran to it, the total mass of the mixture: the volume of tetrahydrofuran is 1:5, stir and mix well, heat to 102°C, and stir while heating to obtain Adhesive matrix;

[0045] (2) Preparation of the first modifying agent: mix nanocellulose, magnesium sulfate, iron oxide and aluminum oxide and grind them into powder, add sulfuric acid solution with a mass fraction of 28% therein, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com