Semi-dull high-strength low-elongation viscose fiber and preparation method thereof

A viscose fiber, high-strength and low-elongation technology, applied in the field of semi-matte high-strength and low-elongation viscose fiber and its preparation, can solve the problem that the development and industrial upgrading of new downstream textiles cannot be met to a greater extent, and the market share of viscose fiber is reduced. and other problems, to achieve the effect of high product strength, good color fastness of finished products, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

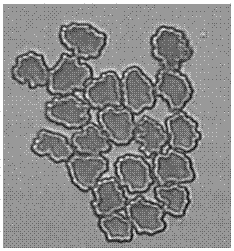

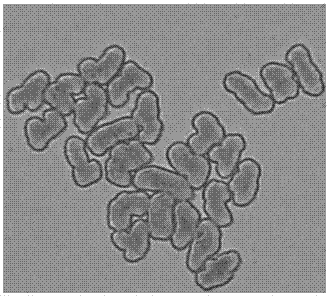

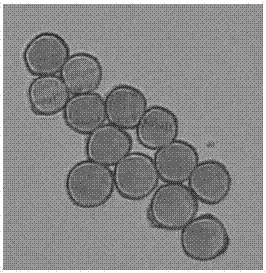

Image

Examples

Embodiment 1

[0063] The pulp raw material is sequentially soaked, ground, crushed, kneaded, depolymerized, yellowed, dissolved, filtered, defoamed, matured, matting agent is added, spinning and drawing, refining and drying to obtain semi-dull viscose. Adhesive fiber, the semi-dull high-strength low-elongation viscose adhesive fiber of the present embodiment has the following performance index system:

[0064] The fineness is 1.67 dtex, the dry breaking strength is 3.12 cN / dtex, the wet breaking strength is 1.65cN / dtex,

[0065] The strength required to produce 5% elongation in wet state is 0.55cN / dtex,

[0066] Dry elongation at break is 19.0%, wet elongation at break is 21.0%,

[0067] The crystallinity is 40%, the radial water swelling degree is 22%, and the content of matting agent is 0.1%.

[0068] The linear density deviation rate is -11.0%, the residual sulfur is 8.0mg / 100g,

[0069] The length deviation rate is -11.0%, the ultra-long fiber rate is 0.48%, and the whiteness is 84.1...

Embodiment 2

[0072] The difference between the semi-dull high-strength low-elongation viscose fiber of the present embodiment and embodiment 1 is: the present embodiment has the following indicators:

[0073] Denier is 1.52 dtex, dry breaking strength is 3.15 cN / dtex, wet breaking strength is 1.67cN / dtex,

[0074] The strength required to produce 5% elongation in wet state is 0.54cN / dtex,

[0075] The dry elongation at break is 18.9%, and the wet elongation at break is 20.8%.

[0076] The crystallinity is 40%, the radial water swelling degree is 22.5%, and the matting agent content is 0.75%.

[0077] The whiteness is 84.6%, the linear density deviation rate is -10.0%, the residual sulfur is 8.0mg / 100g,

[0078] The length deviation rate is +10.0%, and the ultra-long fiber rate is 0.5%,

[0079] The double-length fiber is 4.0mg / 100g, and the defect is 4.0mg / 100g.

Embodiment 3

[0081] In order to better implement the present invention, this embodiment further provides the semi-dull high-strength low-elongation viscose fiber of the present invention and its preparation method, and measures the performance index.

[0082] Semi-dull high-strength low-elongation viscose fiber and its preparation method: the pulp raw material is soaked and pressed to remove the lye to obtain alkali cellulose; the prepared alkali cellulose is crushed, kneaded, and polymerized to remove the lye to obtain Methyl cellulose; the obtained methyl cellulose is yellowed to obtain cellulose sulfonate; the obtained cellulose sulfonate is dissolved in a solvent, filtered, matured, defoamed, and a spinning solution is obtained; After adding matting agent, the spinning solution is sent to spinning machine for spinning and drafting to obtain tow, and the tow is refined and dried to obtain viscose fiber of the present invention. Samples were taken, and each index was measured according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pulverization | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| pulverization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com