α-alumina carrier for silver catalyst and its preparation method and application

A technology of alumina carrier and silver catalyst, which is applied in the direction of catalyst carrier, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve the problems of carrier specific surface reduction, active component aggregation, and technology popularization and application affecting the service life of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the α-alumina carrier involved in the second aspect of the present invention comprises:

[0040] Step A, mixing alumina trihydrate, pseudoboehmite, gallium-containing compounds, silicon-containing compounds, alkaline earth metal compounds and fluoride-containing compounds to obtain a solid mixture;

[0041] Step B, adding a binder and water to the solid mixture to obtain an α-alumina precursor mixture;

[0042] In step C, the α-alumina precursor mixture is kneaded, shaped, dried and calcined to obtain an α-alumina carrier.

[0043] In the present invention, alumina trihydrate and pseudo-boehmite are used as precursors to be converted into α-alumina through high-temperature calcination. In some implementations of the present invention, for example, in step A, the mass ratio of alumina trihydrate to pseudo-boehmite is (0.5-8.0):1.

[0044] In the present invention, the alumina trihydrate includes one or more of gibbsite, pyrenite and nogisite. ...

Embodiment 1

[0085] (1) Preparation of carrier: Weigh 360.0g gibbsite, 240.0g pseudoboehmite, 6.0g ammonium fluoride, 2.0g barium sulfate, 2.5g sodium silicate, 0.9g gallium sulfate, put into the mixture Mix evenly in the container, transfer to the kneader, add dilute nitric acid (nitric acid: water = 1:3, volume ratio) until kneaded into a paste that can be extruded, put the paste into the extruder, Extrude into a seven-hole column, dry at 60-120°C for more than 24 hours to reduce the free water content to below 10%, and then put the dried seven-hole column into a natural gas kiln for roasting at 1300°C , roasted at constant temperature for 20h, and finally cooled to room temperature to obtain α-alumina carrier. The relevant physical property data of the α-alumina carrier prepared in Example 1 are shown in Table 1.

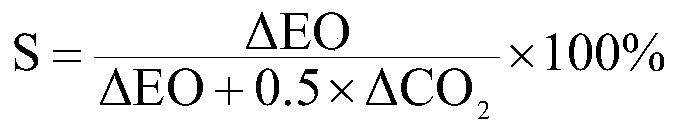

[0086] (2) Preparation of catalyst: take by weighing 140g silver nitrate and dissolve in 150ml deionized water, take by weighing 64g ammonium oxalate and dissolve in 520ml dei...

Embodiment 2

[0089] (1) Preparation of carrier: Weigh 360.0g gibbsite, 240.0g pseudoboehmite, 6.0g ammonium fluoride, 2.0g barium sulfate, 4.0g sodium silicate, 0.2g gallium oxide, put into the mixture Mix evenly in the container, transfer to the kneader, add dilute nitric acid (nitric acid: water = 1:3, volume ratio) until kneaded into a paste that can be extruded, put the paste into the extruder, Extrude into a seven-hole column, dry at 60-120°C for more than 24 hours to reduce the free water content to below 10%, and then put the dried seven-hole column into a natural gas kiln for roasting at 1300°C , roasted at constant temperature for 10h, and finally cooled to room temperature to obtain α-alumina carrier. The relevant physical property data of the α-alumina carrier prepared in Example 2 are shown in Table 1.

[0090] (2) The preparation method of the catalyst is the same as in Example 1.

[0091] (3) The performance evaluation of the catalyst is the same as in Example 1, and the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

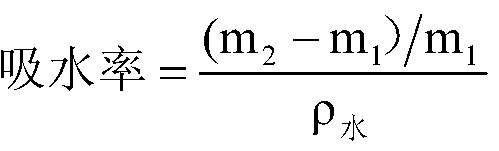

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com