Phosphorylated polyvinyl alcohol/perfluorosulfonic acid resin compound and ion exchange membrane

A technology of perfluorosulfonic acid resin and polyvinyl alcohol, applied in electrochemical generators, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problems of low phosphoric acid content, limited proton exchange membrane performance, and difficulty in improving it. Achieve proper water absorption, excellent physical and mechanical properties, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] According to the phosphorylated polyvinyl alcohol / perfluorosulfonic acid resin composite according to the embodiment of the present invention, the preparation method of the phosphorylated polyvinyl alcohol comprises:

[0044] a, polyvinyl alcohol is dissolved in a solvent to make a polyvinyl alcohol dispersion, wherein the solvent includes at least one of a high-boiling point organic solvent, water or a low-level aliphatic alcohol aqueous dispersion, wherein the high-boiling point The organic solvent is selected from at least one of ethylene glycol, propylene glycol, glycerol, N,N-dimethylformamide, N,N-dimethylacetamide, dimethyl sulfoxide, and N-methylpyrrolidone ; The lower fatty alcohol is selected from at least one of methanol, ethanol, n-propanol, isopropanol, n-butanol or isobutanol;

[0045] b. Adding a phosphoric acid functionalization reagent and a catalyst to the polyvinyl alcohol dispersion in step a to carry out a functionalization reaction, the reaction te...

Embodiment 1

[0064] Embodiment 1 prepares phosphorylated polyvinyl alcohol

[0065] Weigh 500g of polyvinyl alcohol and dissolve it in 10kg of deionized water at 90°C, add 1kg of concentrated phosphoric acid and 200g of urea, react at 140°C and 5MPa for 6h, add isopropanol to obtain a polymer precipitate, and then pass through isopropanol After washing, dry to obtain pure phosphorylated polyvinyl alcohol. The functionality of the phosphate group of the polymer was determined to be 19.8% by proton nuclear magnetic spectroscopy.

[0066] Soak 5 g of the solid product in 10 mL of ethanol, add a magnet to stir, centrifuge with a centrifuge after 30 days, and take the supernatant to determine the phosphoric acid content. The phosphorous content in the supernatant was measured using Thermo Fisher's Inductively Coupled Plasma Mass Spectrometer (ICP-MS), and the phosphoric acid content was calculated from the phosphorous content. The phosphorus content of the supernatant is only 8ppm, indicating...

Embodiment 2

[0067] Example 2 Preparation of highly functionalized phosphorylated polyvinyl alcohol

[0068] Weigh 50g of polyvinyl alcohol and dissolve it in 500mL of dimethyl sulfoxide at 120°C, add 100g of polyphosphoric acid without adding additional catalyst, and react with stirring at 160°C for 6h under the protection of nitrogen. The addition of methanol resulted in the precipitation of the polymer, which was dried to obtain pure phosphorylated polyvinyl alcohol. The functionality of the phosphate group of the polymer was determined to be 59.8% by proton nuclear magnetic spectroscopy. The method does not need to add additional catalyst, and the obtained product has a high degree of functionalization.

[0069] Soak 5 g of the solid product in 10 mL of ethanol, add a magnet to stir, centrifuge with a centrifuge after 30 days, and take the supernatant to determine the phosphoric acid content. The phosphorus content of the supernatant was measured by ICP-MS to be 12ppm, and the phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

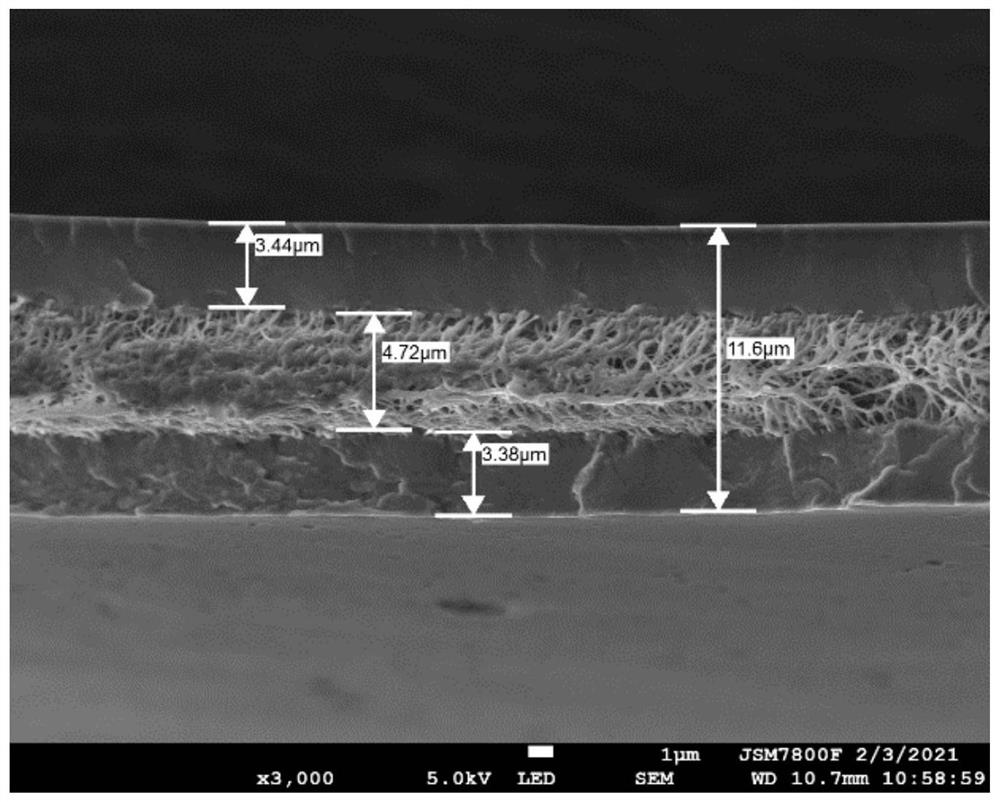

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com