High-strength viscose fibers and preparation method and application of high-strength viscose fibers

A viscose fiber, high-strength technology, applied in the field of high-strength viscose fiber and its preparation, can solve the problems of high cost and the like, and achieve the effects of improving reaction performance, strong skin affinity, and low semi-fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

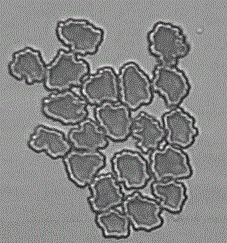

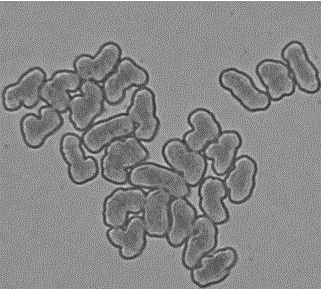

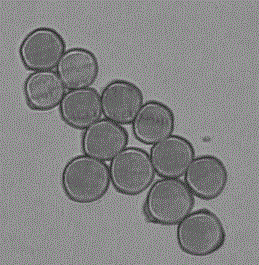

Image

Examples

Embodiment

[0096] The high-strength viscose fiber that the present invention relates to satisfies:

[0097] Denier 0.80D, dry breaking strength 3.15cN / dtex, wet breaking strength 1.7cN / dtex,

[0098] The strength required to produce 5% elongation in wet state is 0.60cN / dtex,

[0099] Dry elongation at break 15.0%, wet elongation at break 18.0%,

[0100] The crystallinity is 40.0%, the radial water swelling degree is 22%,

[0101] Linear density deviation rate -2%, whiteness 83%,

[0102] Residual sulfur 7.0mg / 100g, length deviation rate +0.5%,

[0103] Super long fiber rate 0%, double long fiber 0mg / 100g,

[0104] Defect 0.5mg / 100g.

Embodiment 2

[0106] The preparation process of the high-strength viscose fiber involved in this embodiment has the following steps:

[0107] A: impregnate pulp raw materials with lye, and then grind, squeeze, pulverize and knead to make pulp porridge;

[0108] B: Mix the porridge with lye and send it into the reactor, and obtain alkali cellulose after depolymerization;

[0109] C: using a solvent to dissolve the cellulose sulfonate obtained by the reaction of alkali cellulose and carbon disulfide to obtain a cellulose sulfonate solution;

[0110] D: The cellulose sulfonate solution is filtered, defoamed, and matured to obtain a spinning solution, and then the obtained spinning solution is subjected to spinning, drafting and post-treatment to obtain a high-strength viscose fiber.

Embodiment 3

[0112] The difference between this embodiment and embodiment 2 is that: in the step A involved in this embodiment, the pulp raw material with a degree of polymerization of 650 is soaked in a sodium hydroxide solution with a concentration of 110g / L for 50min, and then ground by a grinder, squeezed, After pulverizing and kneading, it is made into porridge, and the concentration of the porridge is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com