An accelerating agent used for printing and dyeing of linen and a using method thereof

A technology of flax fabric and dyeing accelerator, which is applied in the field of textile industry, can solve the problems of limited dye adsorption, unsatisfactory dyeing rate and dyeing fastness of flax fibers, etc., and achieve high dyeing rate and dyeing fastness, high Industrial promotion value, the effect of increasing vividness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Preparation of dyeing accelerators for linen fabric printing and dyeing:

[0029] Lanthanum chloride (based on the amount of rare earth elements) 2 parts, chitosan (molecular weight 700,000-800,000) 2 parts, sodium chloride 1 part, 2,4,5-trichlorophenol 15 parts, citric acid 5 parts , 100 parts of water.

[0030] Dyeing method: Prepare the dyeing solution, adjust the dyeing solution to the specified pH, heat the constant temperature water bath to a certain temperature, dye the fabric, heat to the specified temperature, heat at a constant temperature, take it out, wash it, and dry it.

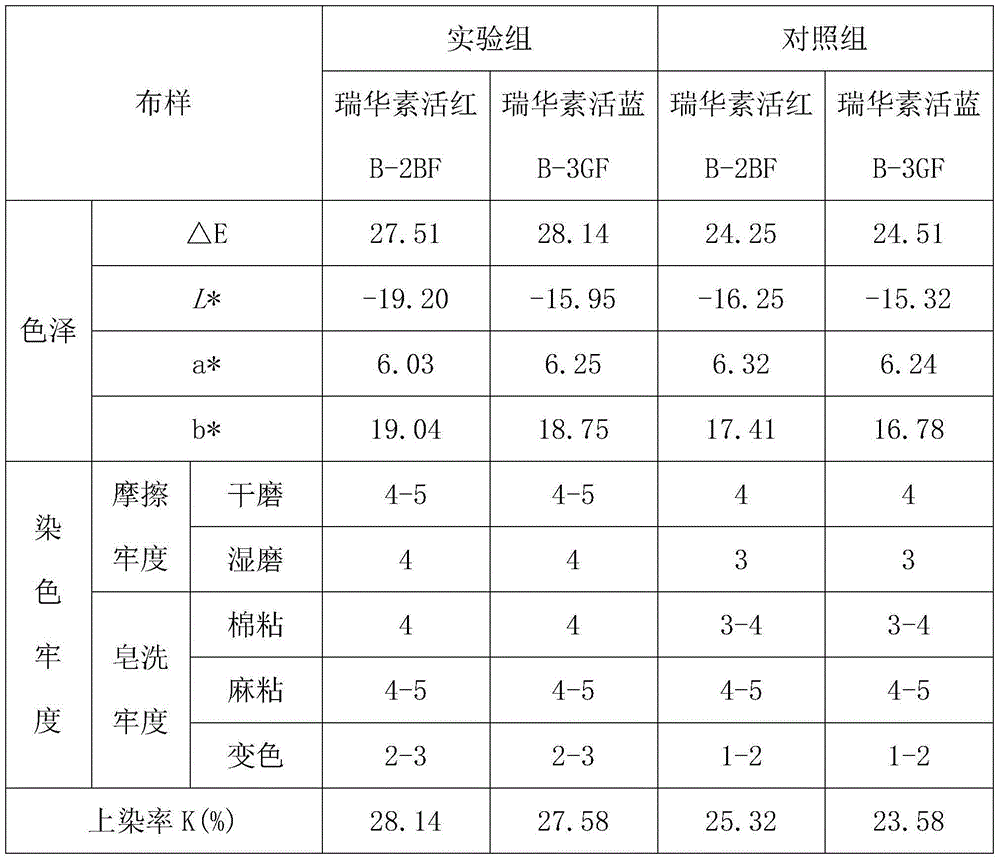

[0031] Among them, the dye pigment is Ruihuasu reactive red B-2BF or Ruihuasu reactive blue B-3GF, the dyeing temperature is 60°C, the dyeing acceleration time is 30min, the color fixing time is 30min, the sample cloth weight is 2g, and the liquor ratio is 1:50.

[0032] Accelerator treatment method:

[0033] Step 1: Stir each component evenly according to the parts by mass to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com