Method of blending combustion of fuel coal fly ash in biomass circulating fluidized bed boiler and a device thereof

A circulating fluidized bed and biomass technology, applied in the direction of fluidized bed combustion equipment, combustion methods, combustion equipment, etc., can solve the problems of reducing production load, only stop production, and the advent of technical solutions, so as to reduce consumption and increase power generation. The effect of hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The equipment and process of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

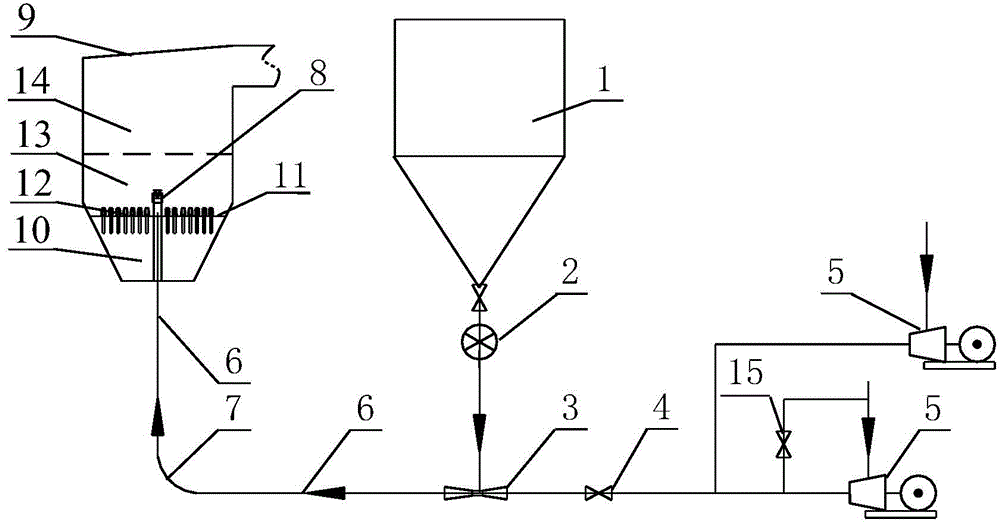

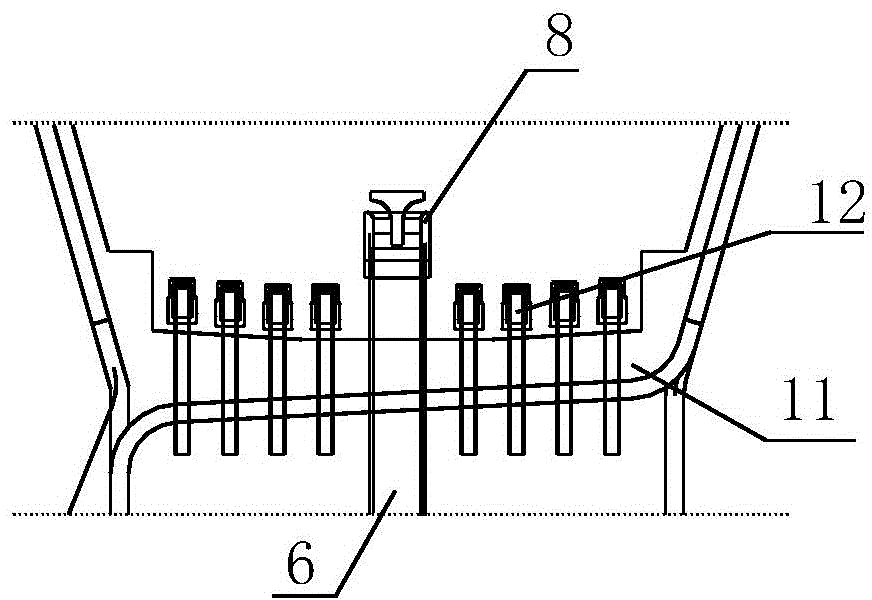

[0035] The biomass circulating fluidized bed boiler shown in the figure blends coal-fired fly ash equipment with a coal-fired fly ash storage bin 1 used in conjunction with a biomass circulating fluidized bed boiler 9 . The bottom outlet of the coal-fired fly ash storage bin 1 is connected to the powder input end of the injector 3 through the rotary feeding device 2. The rotary feeding device 2 adopts a rotary feeding valve remotely controlled by a frequency converter to precisely control the coal-fired fly ash. The amount of fly ash delivered. The air input end of the ejector 3 is connected to the blower 5 through the check valve 4, the blower 5 is a Roots blower, two sets of Roots blowers are arranged side by side, and one set of Roots blowers is provided with a vent valve 15, which can be installed acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com