A detection device for an intelligent metering detection unit

A technology of measurement detection and detection devices, which is applied in the field of detection devices and detection devices of intelligent measurement detection units, which can solve the problems of easy oil pollution, reduced precision of machine tools, and low inspection efficiency, so as to avoid wear of measuring instruments and reduce manual participation , High detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

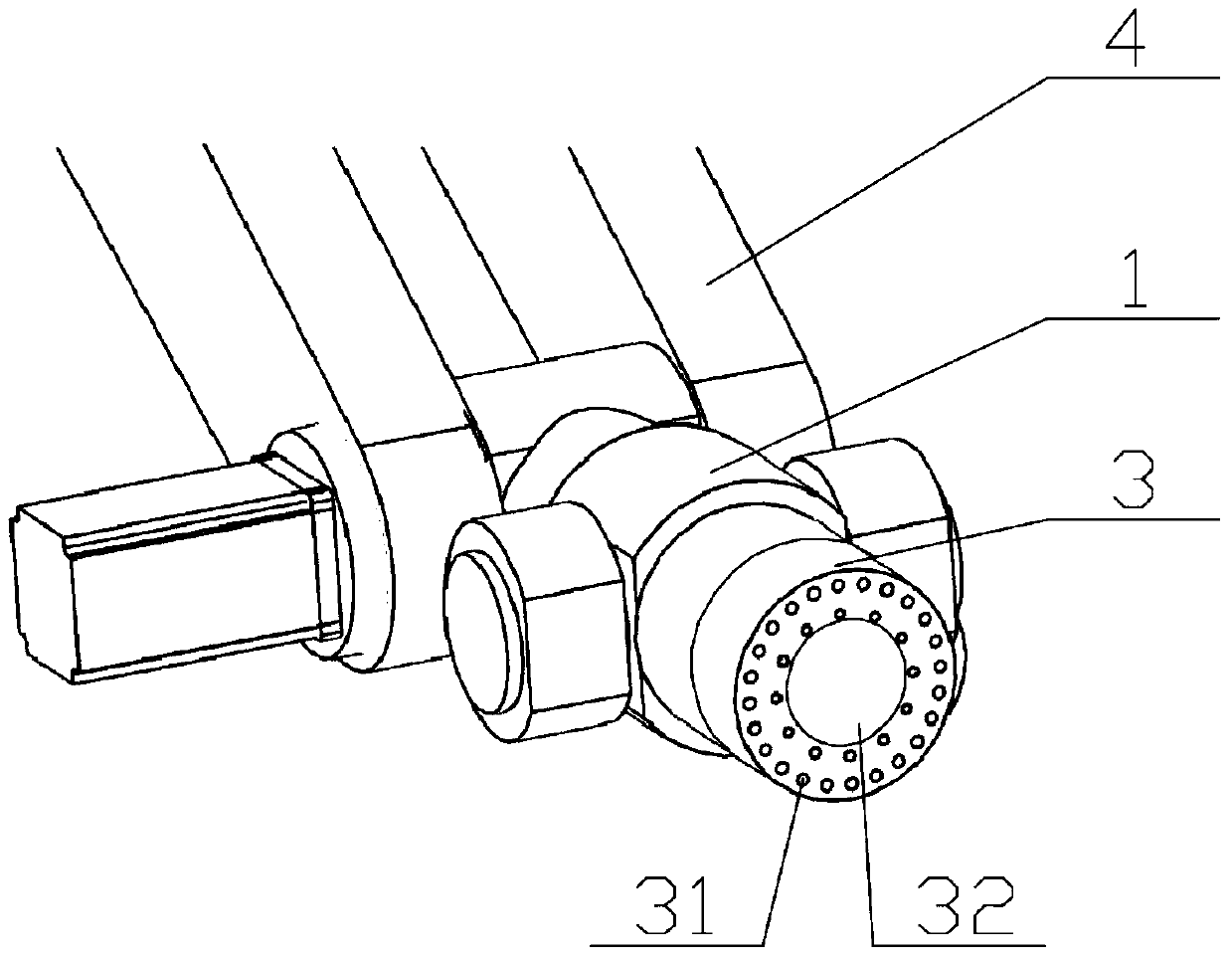

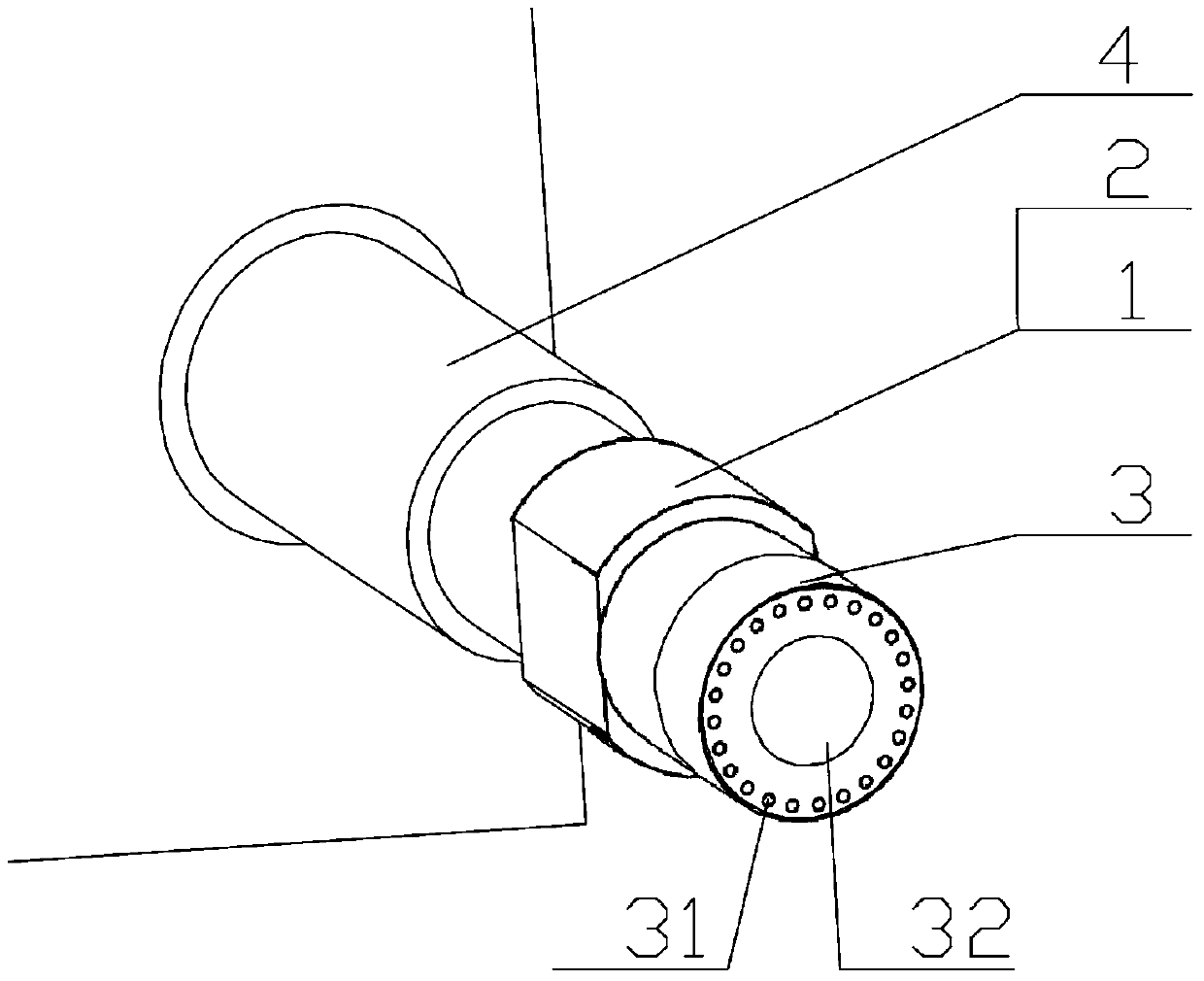

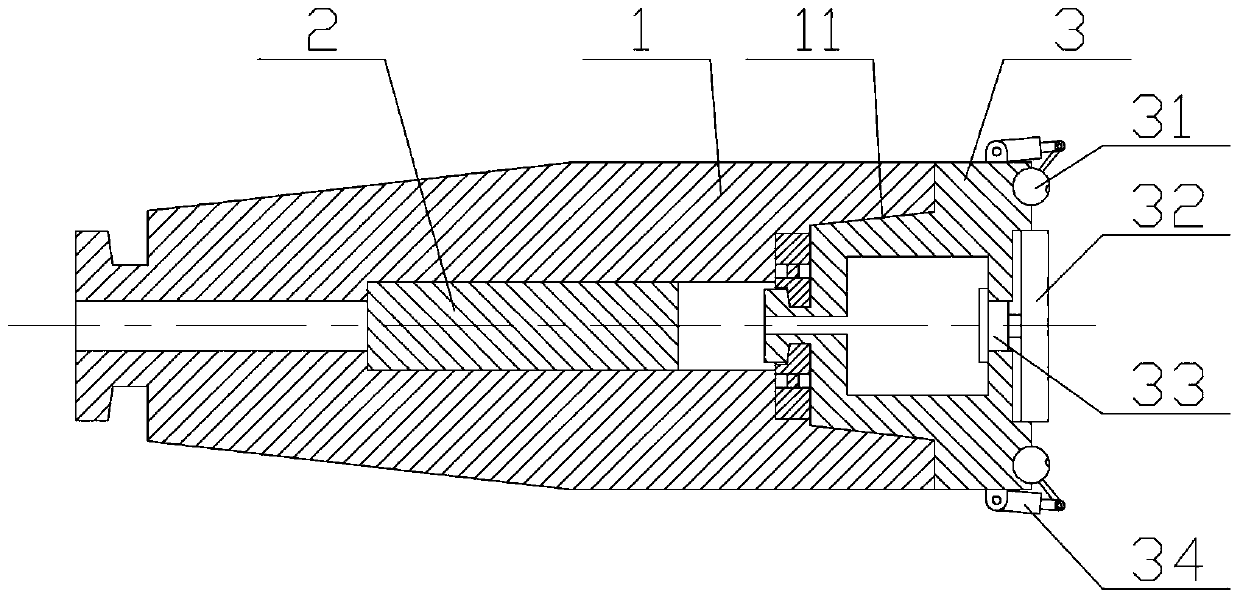

[0052] As an embodiment of the present invention, the detection medium transmitter 31 and the detection medium feedback receiver 32 are a light source transmitter and a light source feedback receiver.

[0053] In order to measure the measured workpiece 6 more accurately, as a further improvement of the present invention, the multiple detection medium emitters 31 that are uniformly distributed in a circle on the front end surface of the detection head 3 respectively emit light sources of different wavelengths and frequencies, The detection medium feedback receiver 32 receives light source signals of different wavelengths and frequencies and converts them to the data processing module of the electric control mechanism 2. The data processing module sends the layer data to the central processing unit for storage through the data sending module. The data analysis and processing circuit is based on Perform data continuity analysis, characteristic analysis, and numerical approximation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com