Thin film multilayered flocking high-elastic antibiosis warmth keeping flaky material and manufacturing method thereof

A sheet-like material and flocking technology, applied in the textile field, to achieve the effect of improving warmth retention, reducing usage, and ensuring air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

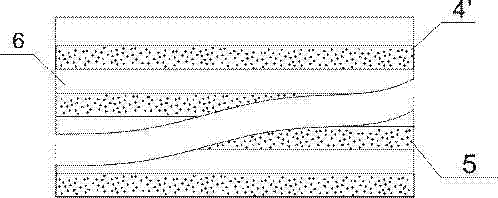

[0051] Strip-shaped film flocking type machine-laid high-elastic antibacterial and warm-keeping sheet material and its preparation method:

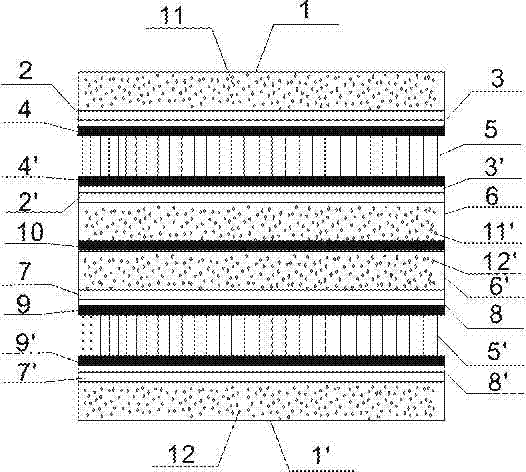

[0052] see figure 1 , figure 2 , film multi-layer flocking type high elastic antibacterial and warm sheet material, including upper fiber web 1, upper hot-melt film 2, upper flocking film substrate 3, upper adhesive film 4, upper fluff 5, middle and upper bonding Agent film 4', middle and upper flocking film substrate 3', middle and upper hot-melt film 2', middle and upper fiber web 6, hot-melt film 10, middle and lower fiber web 6', middle and lower hot-melt film 7, middle and lower Flocking film substrate 8, middle and lower adhesive film 9, lower fluff 5', lower adhesive film 9', lower flocking film substrate 8', lower hot-melt film 7', lower fiber web 1', Antimicrobials 11, 11 , , 12, 12 ,. The upper fiber web 1, the middle and upper layer fiber web 6, the middle and lower layer fiber web 6', and the lower layer fiber web 1' are...

Embodiment 2

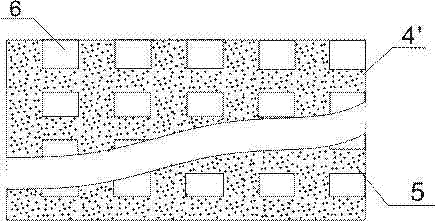

[0068] Grid-shaped film flocking type mechanically-laid high-elastic antibacterial and warm-keeping sheet material and its preparation method:

[0069] see figure 1 , image 3 , film multi-layer flocking type high elastic antibacterial and warm sheet material, including upper fiber web 1, upper hot-melt film 2, upper flocking film substrate 3, upper adhesive film 4, upper fluff 5, middle and upper bonding Agent film 4', middle and upper flocking film substrate 3', middle and upper hot-melt film 2', middle and upper fiber web 6, hot-melt film 10, middle and lower fiber web 6', middle and lower hot-melt film 7, middle and lower Flocking film substrate 8, middle and lower adhesive film 9, lower fluff 5', lower adhesive film 9', lower flocking film substrate 8', lower hot-melt film 7', lower fiber web 1', Antimicrobials 11, 11 , , 12, 12 , . The upper fiber web 1, the middle and upper layer fiber web 6, the middle and lower layer fiber web 6', and the lower layer fiber web 1'...

Embodiment 3

[0085] Strip-shaped film flocking air-laid high-elastic antibacterial and warm-keeping sheet material and its preparation method:

[0086] see figure 1 , figure 2 , film multi-layer flocking type high elastic antibacterial and warm sheet material, including upper fiber web 1, upper hot-melt film 2, upper flocking film substrate 3, upper adhesive film 4, upper fluff 5, middle and upper bonding Agent film 4', middle and upper flocking film substrate 3', middle and upper hot-melt film 2', middle and upper fiber web 6, hot-melt film 10, middle and lower fiber web 6', middle and lower hot-melt film 7, middle and lower Flocking film substrate 8, middle and lower adhesive film 9, lower fluff 5', lower adhesive film 9', lower flocking film substrate 8', lower hot-melt film 7', lower fiber web 1', Antimicrobials 11, 11 , , 12, 12 , . The upper fiber web 1, the middle and upper layer fiber web 6, the middle and lower layer fiber web 6', and the lower layer fiber web 1' are three-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com