Environment-friendly wool and SRN fiber blending jacquard warm-keeping knitted fabric

A fiber blending and knitted fabric technology, applied in knitting, fiber treatment, weft knitting and other directions, can solve the problems of easy mildew, fabric performance needs to be improved, low breaking strength, etc., to improve wrinkle resistance, air permeability, The effect of skin care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

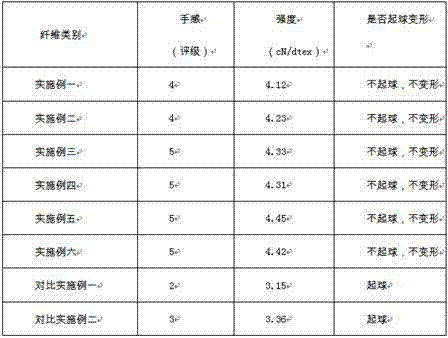

Examples

Embodiment 1

[0026] 70wt% wool, 30wt% SRN fiber blend combination, pre-drawing, sliver winding, carding, winding, fixed twisting to make blended yarn;

[0027] Same-color dyeing of blended yarn: including steps in turn: single-side singeing, boiling and bleaching, setting, mercerizing, disperse hot-melt dyeing and color registration; the single-side singeing process is specifically gas singeing, singeing twice on the front of the two burners, The speed of the vehicle is 80m / min, including after disperse hot-melt dyeing, and the color registration is carried out with reactive dyes or Shihlin dyes;

[0028] Chromatography is to use reactive dyes or Shihlin dyes for chromatography; the specific method of disperse hot-melt dyeing is: semi-finished products are dipped and rolled with disperse dyes, using four dips and one rolling method, the excess rate is 40%, and then dried at 60 ° C for 30 seconds , bake at 100°C for 45 seconds, then use caustic soda with a concentration of 25g / L and hydrosu...

Embodiment 2

[0033] 60wt% wool, 40wt% SRN fiber blend combination, pre-drawing, sliver winding, carding, winding, fixed twisting to make blended yarn;

[0034] Same-color dyeing of blended yarn: including steps in turn: single-side singeing, boiling and bleaching, setting, mercerizing, disperse hot-melt dyeing and color registration; the single-side singeing process is specifically gas singeing, singeing twice on the front of the two burners, The vehicle speed is 85m / min, including after disperse hot-melt dyeing, and the color registration is carried out with reactive dyes or Shihlin dyes;

[0035] Chromatography is to use reactive dyes or Shihlin dyes for chromatography; the specific method of disperse hot-melt dyeing is: semi-finished products are dipped and rolled with disperse dyes, using four dips and one rolling method, the excess rate is 65%, and then dried at 80 ° C for 60 seconds , bake at 120°C for 60 seconds, then use caustic soda with a concentration of 30g / L and hydrosulfite r...

Embodiment 3

[0041] 80wt% wool, 20wt% SRN fiber blend combination, pre-drawing, sliver and winding, carding, winding, fixed twisting to make blended yarn;

[0042] Same-color dyeing of blended yarn: including steps in sequence: turning cloth, singeing on one side, boiling and bleaching, setting, mercerizing, disperse hot-melt dyeing and color registration; the single-side singeing process is specifically gas singeing, singeing on the front of two burners Twice, with a speed of 82m / min including after disperse hot-melt dyeing, the color registration is carried out with reactive dyes or Shihlin dyes;

[0043] Chromatography is to use reactive dyes or Shihlin dyes for chromatography; the specific method of disperse hot-melt dyeing is: semi-finished products are dipped and rolled with disperse dyes, using four dips and one rolling method, with a pass rate of 55%, and then dried at 70°C for 50 seconds , bake at 110°C for 50 seconds, then use caustic soda with a concentration of 28g / L and hydros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| warmth retention rate | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com