Method of producing bleached chemi-mechanical pulp from Eucalyptus sheets

A technology of eucalyptus chips and mechanical pulp, applied in pulp beating/refining methods, pulp bleaching, pulp dehydration, etc., can solve problems such as high moisture content, relatively high requirements, and impact, and achieve good results and simplify the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The first step, the preparation of raw materials: the eucalyptus wood chip raw material is firstly washed with hot water, the temperature of the hot water is 75°C, and the preheating storage period of the hot water washing of the eucalyptus wood chip is 35 minutes.

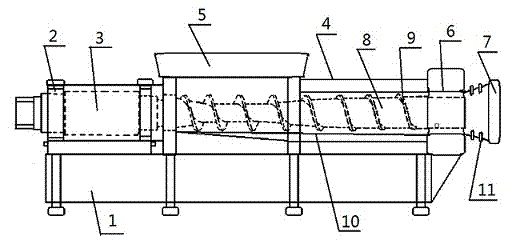

[0021] The second step is extrusion tearing and dehydration: the single-screw extruder with a variable-diameter conical structure in which the diameter of the spiral cone shaft decreases first and then becomes larger, and a variable-pitch structure in which the pitch of the spiral blades gradually increases. The material is subjected to extrusion, tearing and dehydration treatment. During extrusion, tearing and dehydration, the volume compression ratio of the raw material and the compressed material is 3.5:1. After extrusion, tearing and dehydration, the material becomes a multi-gap loose filament sponge, with a moisture content of 25%. wt.

[0022] The third step, one-time dipping and bleaching: put the mu...

Embodiment 2

[0028] The first step, the preparation of raw materials: first wash the eucalyptus wood chips raw material with hot water, the temperature of the hot water is 80°C, and the preheating storage period of the hot water washing of the eucalyptus wood chips in the preparation of raw materials is 40 minutes;

[0029]The second step is extrusion tearing and dehydration: the single-screw extruder with a variable-diameter conical structure in which the diameter of the spiral cone shaft decreases first and then becomes larger, and a variable-pitch structure in which the pitch of the spiral blades gradually increases. The material is subjected to extrusion, tearing and dehydration treatment. During extrusion, tearing and dehydration, the volume compression ratio of the raw material and the compressed material is 3.6:1. After extrusion, tearing and dehydration, the material becomes a multi-gap loose filament sponge, with a moisture content of 21%. wt.

[0030] The third step, one-time dip...

Embodiment 3

[0036] The first step, the preparation of raw materials: the eucalyptus wood chip raw material is firstly washed with hot water, the temperature of the hot water is 90° C., and the preheating preservation stage time of the hot water washing of the eucalyptus wood chip is 45 minutes.

[0037] The second step is extrusion tearing and dehydration: the single-screw extruder with a variable-diameter conical structure in which the diameter of the spiral cone shaft decreases first and then becomes larger, and a variable-pitch structure in which the pitch of the spiral blades gradually increases. The material is subjected to extrusion, tearing and dehydration treatment. During the extrusion, tearing and dehydration, the volume compression ratio of the raw material and the compressed material is 3.8:1. After the extrusion, tearing and dehydration, the material becomes a multi-gap loose filament sponge, with a moisture content of 18%. wt.

[0038] The third step, one-time dipping and bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com