A kind of compressor with ellipsoid convex structure leading edge blade

An ellipsoid and compressor technology, applied in the field of compressors, can solve the problems of sudden change in curvature and separation of the boundary layer of the blade leading edge, and achieve the effect of suppressing excessive expansion flow, increasing the range of attack angle, and being easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

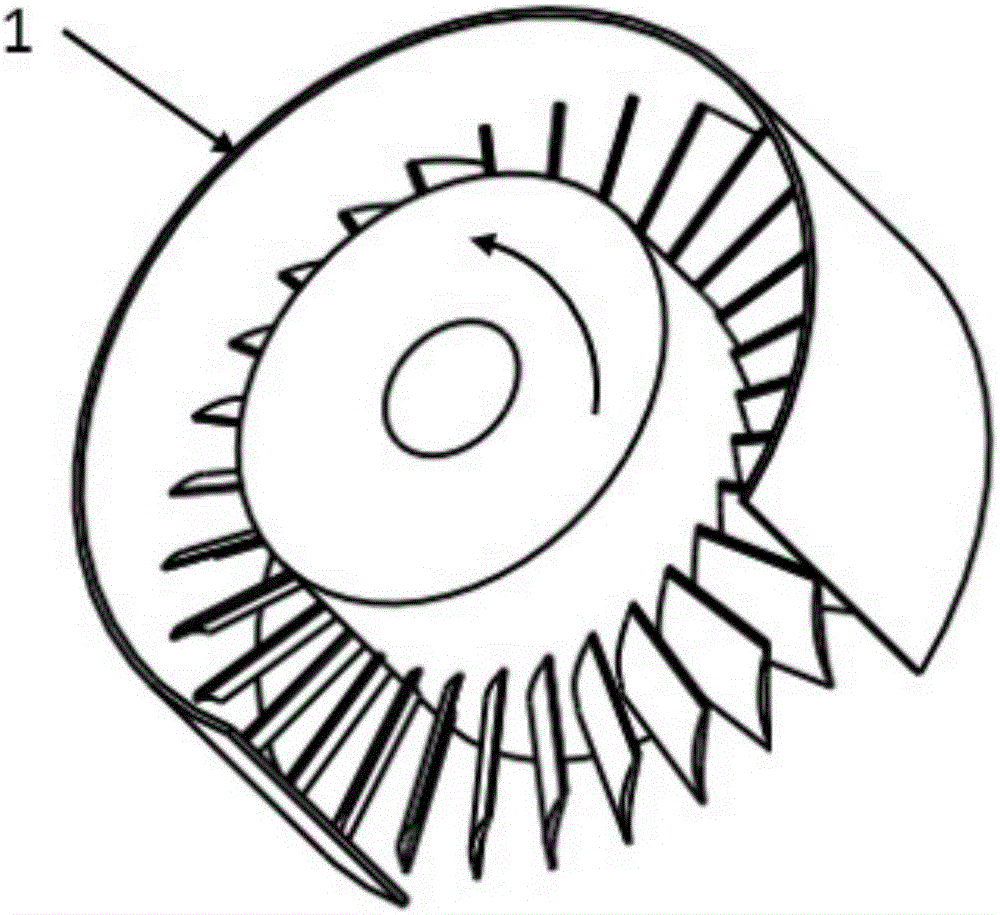

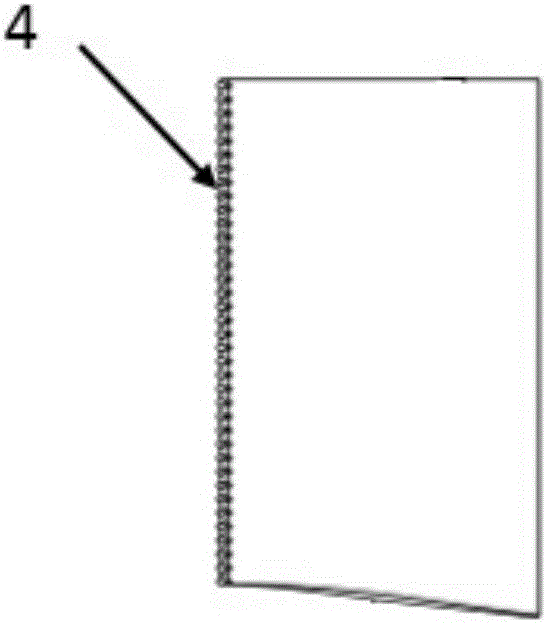

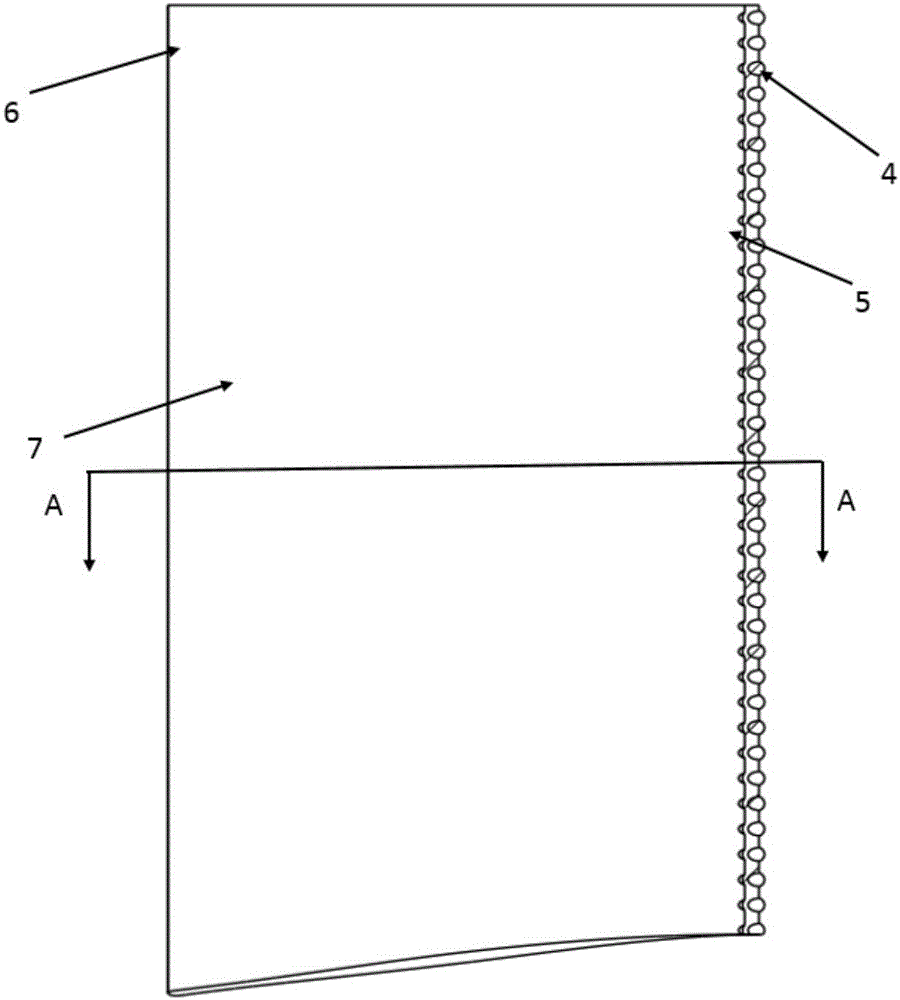

[0019] combine Figure 1~4 , the present invention includes a casing 1, a hub installed in the casing 1, and a blade 7 installed on the hub. The blade 7 generally forms a cascade, and the upper and lower ends of the blade are respectively a suction surface 2 and a pressure surface 3. The two ends are the trailing edge 6 and the leading edge 5, respectively, and the leading edge 5 of the blade is provided with a convoluted leading edge convex structure 4. The cascade with the ellipsoidal convex structure is a cascade with a gradually expanding shape, which is applied to compressed air. Machine blade design technology; the ellipsoidal convex structure is located at the leading edge of the compressor blade, its major axis is 4-7 times of the diameter of the leading edge of the blade, and its minor axis is 0.5-3 times of the diameter of the leading edge, the elliptica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com