Biomass boiler

A biomass boiler, biomass technology, applied in steam boilers, fire tube steam boilers, steam generation and other directions, can solve the problems of large heat loss of chain furnaces, damage to refractory parts, ash accumulation in smoke pipes, etc. The failure rate, reducing the probability of flue blockage, and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

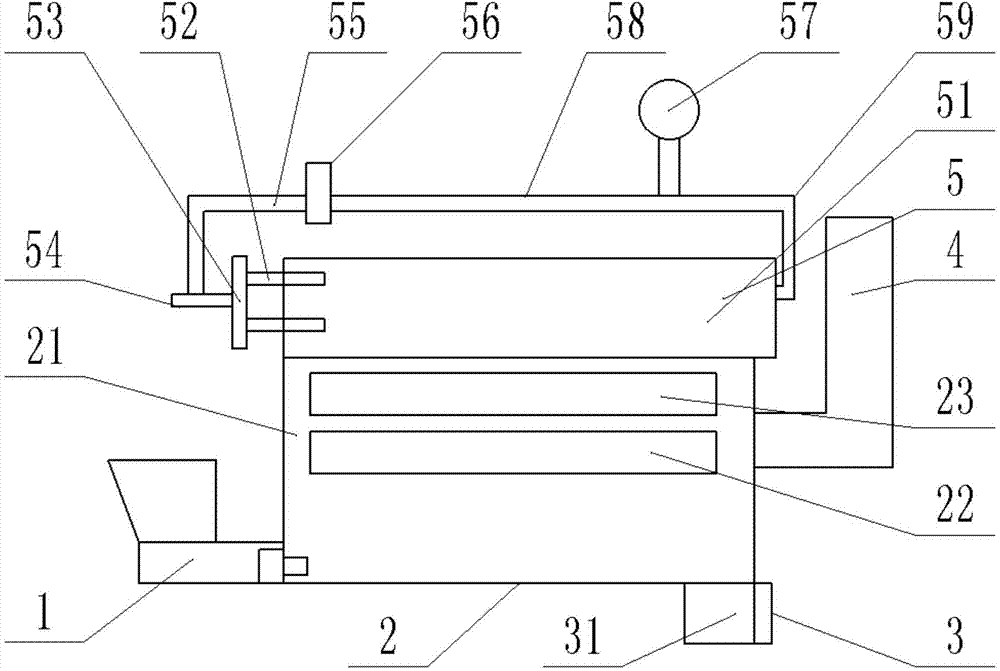

[0011] see figure 1 , a biomass boiler, comprising a biomass burner 1, a horizontal fire tube boiler body 2 and a boiler inlet pipe assembly 5, the biomass burner 1 is connected with a horizontal fire tube boiler body 2, a horizontal fire tube boiler The main body 2 is provided with a furnace 21, and the furnace 21 is provided with a second-pass smoke pipe 22 and a three-pass smoke pipe 23; the tail of the horizontal fire-tube boiler body 2 is provided with a smoke exhaust port 4; The fuel produces high-temperature pyrotechnics and is directly sent into the horizontal fire tube boiler body 2 through the fire outlet. After the pyrotechnics enter the furnace 21, they are heat-exchanged through the second-pass smoke pipe 22 and the three-pass smoke pipe 23 in sequence, and finally the smoke exhaust Port 4 is discharged to the flue gas treatment syste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap