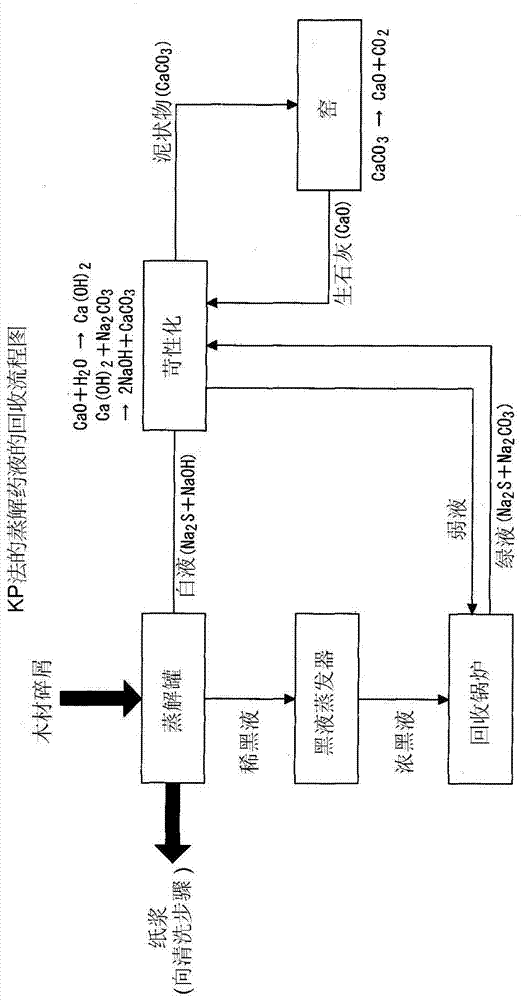

Continuous electrolysis method by means of electrolytic bath for polysulfide manufacturing, and electrolysis device for implementing same

An electrolysis method and electrolytic cell technology are applied in the field of continuous electrolysis using an electrolytic cell for polysulfide production and an electrolytic device for implementing the same, which can solve the problems of producing distillate, difficulty in high selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

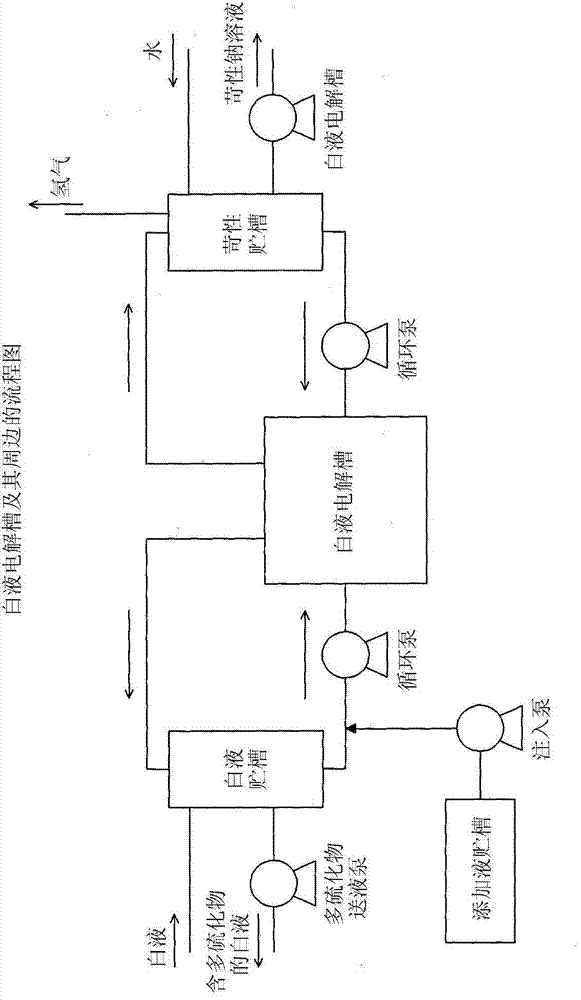

[0071] In white liquor electrolyzers in continuous electrolysis, electrolysis is not stopped, from figure 2 The indicated site was added with an antiscalant (Kurita Kogyo Co., Ltd.: Depoclean 830) at 3.2 mg / l relative to the white liquor, and electrolysis was continued continuously. The electrolytic current density is set to 5.7kA / m 2 , The white liquor temperature is set at 90°C, and the sodium sulfide concentration in the white liquor is set at 30g / l-35g / l. The frequency of adding the anti-scaling agent was repeated two days a week, and as a result, the average cell voltage rise rate for 30 days was 2.4mV / day. In addition, it was confirmed that there was no difference in the polysulfide generation current efficiency regardless of the presence or absence of the addition of the antifouling agent.

Embodiment 2

[0073] In white liquor electrolyzers in continuous electrolysis, electrolysis is not stopped, from figure 2 The indicated site was added with an antiscalant (Kurita Kogyo Co., Ltd.: Depoclean 830) at 3.2 mg / l relative to the white liquor, and electrolysis was continued continuously. The electrolytic current density is set to 5.7kA / m 2 , The white liquor temperature is set at 90°C, and the sodium sulfide concentration in the white liquor is set at 30g / l-35g / l. The frequency of adding the anti-scale agent is repeated two days a week. In addition, in the middle of continuous electrolysis, without stopping the electrolysis, a dirt cleaning agent (Kurita Kogyo Co., Ltd.: Depoclean 505G) was added once a week so as to become 20 g / l in the white liquor storage tank. As a result, the average tank voltage for 30 days increased. The speed is 1.8mV / day. In addition, it was confirmed that there was no difference in the polysulfide generation current efficiency regardless of the presenc...

Embodiment 3

[0075] Stop the white liquor electrolyzer in the continuous electrolysis, replace the anolyte in the white liquor storage tank with 10% sodium hydroxide solution containing 20g / l~50g / l dirt cleaning agent (Kurita Industry Co., Ltd.: Depoclean 505G), After circulating in the anolyte system for 24 hours, white liquor was injected into the white liquor storage tank again, and electrolysis was started in the same manner as in Example 1. An antifouling agent (Kurita Kogyo Co., Ltd.: Depoclean 830) was also added in the same manner as in Example 1 at the restart of electrolysis so as to be 3.2 mg / l with respect to the white liquor, and electrolysis was continued continuously. The electrolytic current density is set to 5.7kA / m 2 , The white liquor temperature is set at 90°C, and the sodium sulfide concentration in the white liquor is set at 30g / l-35g / l. The frequency of adding the anti-scale agent is repeated two days a week. The 30-day average cell voltage increase rate at this ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com