Positive electrode for nonaqueous electrolyte secondary battery, nonaqueous electrolyte secondary battery using positive electrode, and method for producing positive electrode

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolyte battery electrodes, secondary battery manufacturing, non-aqueous electrolyte batteries, etc. High followability improvement effect, excellent adhesion and followability, and battery performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] (Production of positive electrode using polyaniline powder, polyanionic acid and plasticizer)

[0101] 4.69 g of the above-mentioned polyaniline powder in a reduced and dedoped state was mixed with 0.60 g of conductive carbon black (manufactured by Denka Kogyo Co., Ltd., DENKA BLACK) powder, and then added to the above-mentioned polyacrylate lithium salt adjusted to a concentration of 4.20% by weight. In 26.77g of aqueous solution, mix thoroughly with a spatula. Next, as a plasticizer, 0.33 g of a 20% by weight aqueous solution of glycerin (manufactured by Wako Pure Chemical Industries, Ltd., average molecular weight 92) was added, and then ultrasonic treatment was performed for 1 minute with an ultrasonic homogenizer, and then a film rotary high-speed mixer was used. (manufactured by PRIMIX Corporation, FILMICS40-40 type) was slightly dispersed by applying a high shear force to obtain a fluid paste. The paste was further degassed by vacuum suction bell jar and rotary ...

Embodiment 2~19

[0104] (Fabrication of positive electrodes using polyaniline powder, containing polyanionic acids, and containing different types and amounts of plasticizers)

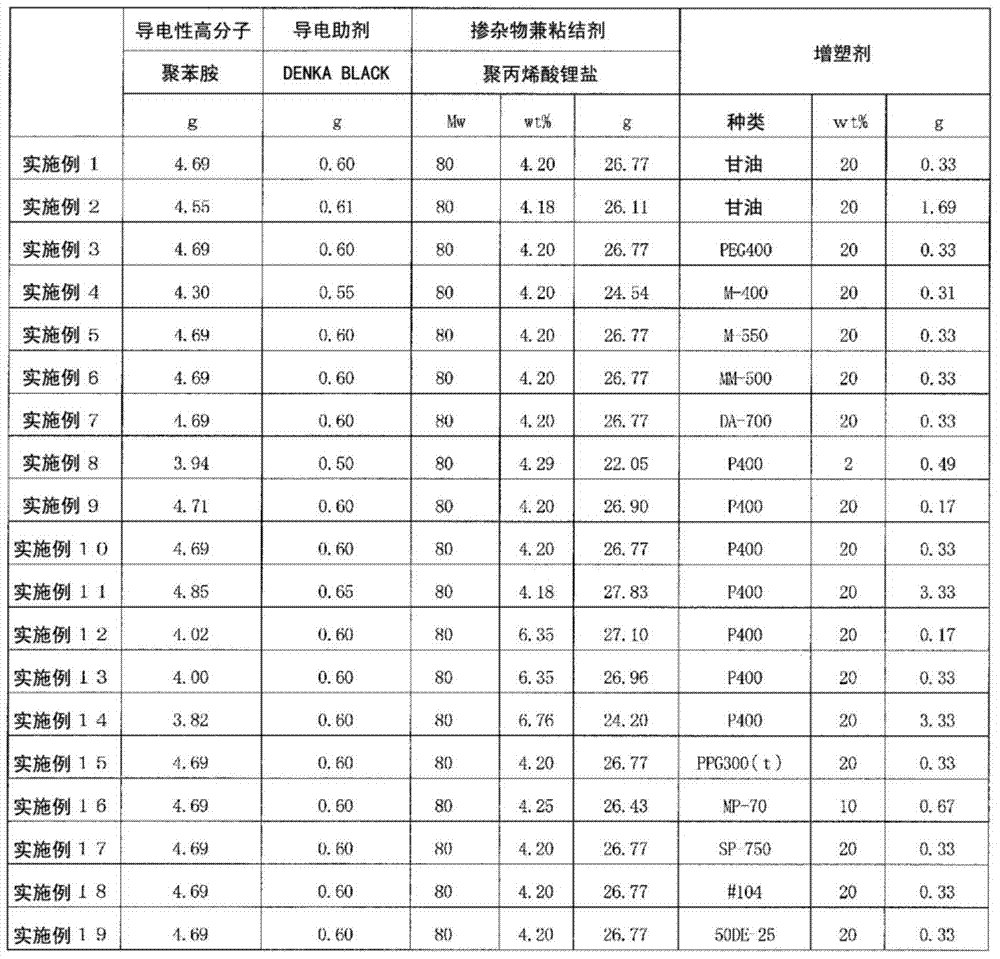

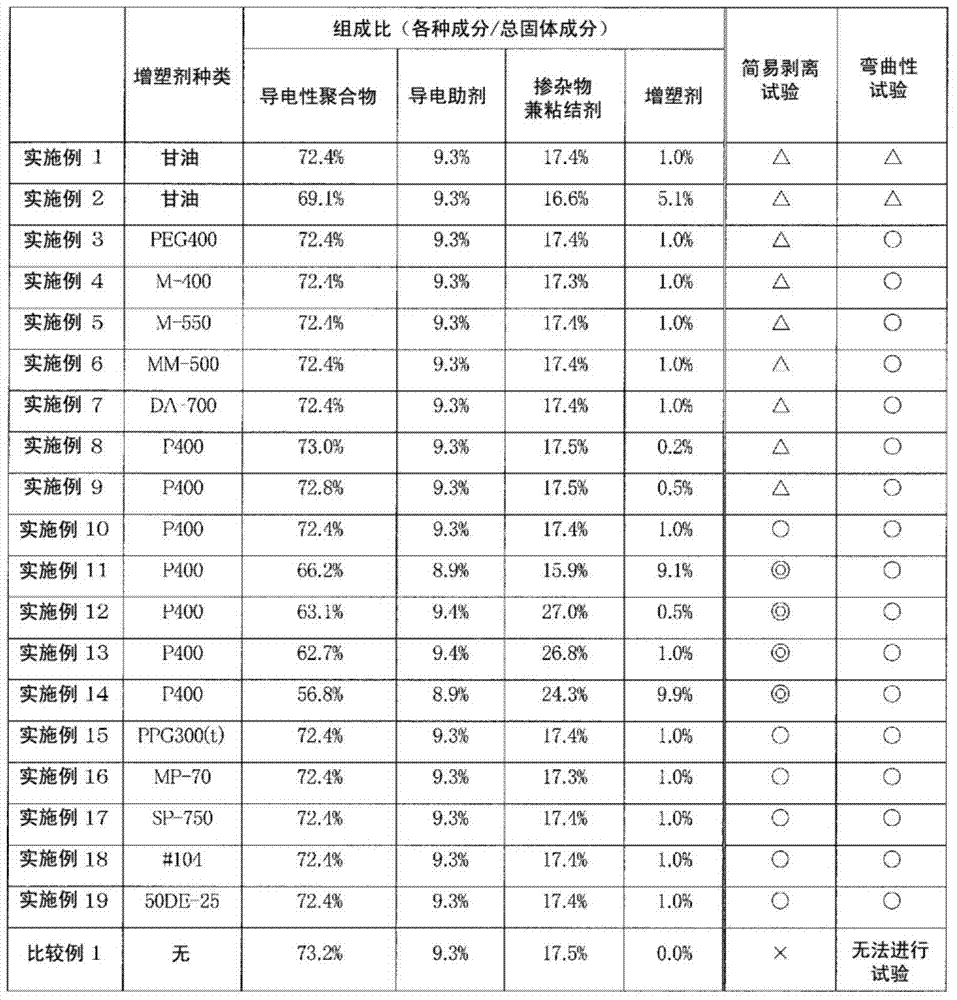

[0105] The positive electrodes of Examples 2 to 19 were produced in the same manner as the production of the positive electrode of Example 1 above except that the ratios of the respective materials were replaced with those shown in Table 1 below.

[0106] [Table 1]

[0107]

[0108] In addition, the detail of the plasticizer used in said Table 1 is shown in following Table 2.

[0109] [Table 2]

[0110] Abbreviation

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com