Gas flow waveform modulation variable polarity plasma welding method

A plasma welding and polarity changing technology, which is applied in plasma welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of poor thermal electron emission capability, serious heat loss, arc divergence, etc., to improve stability and strengthen cooling , Increase the effect of ion gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of gas flow waveform modulation variable polarity plasma welding method in this embodiment, the specific operation is as follows

[0031] Step 1: Before welding, after grinding and cleaning the parts to be welded (4mm thick aluminum alloy), fix them on the welding fixture;

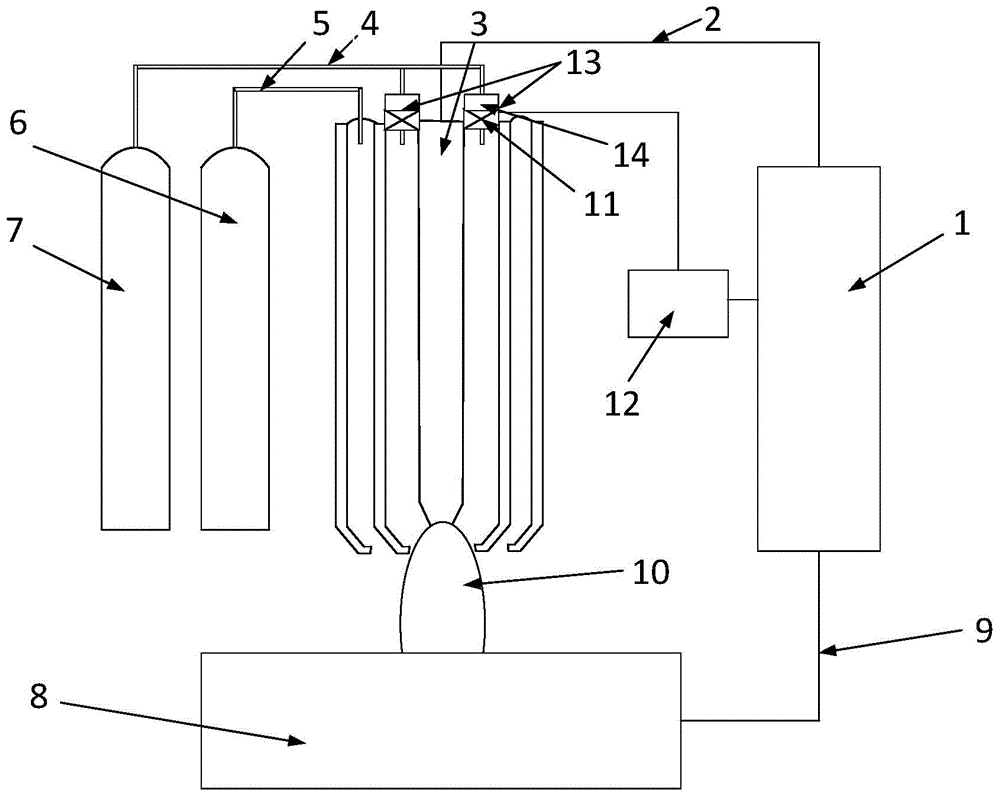

[0032] Step 2: Follow the figure 1 As shown, connect the circuit and gas circuit, make the plasma torch vertical to the upper part of the part to be welded, and connect the air flow waveform controller and ion gas control execution unit into the system;

[0033] Step 3: Set welding process parameters: welding current 80 / 120A, welding speed 0.1m / min, arc height 4mm, shielding gas flow 18L / min, ion gas flow 3L / min and 4L / min, shielding gas and ion gas Use 99.99% argon gas, the time ratio of positive and negative polarity is 21ms:4ms;

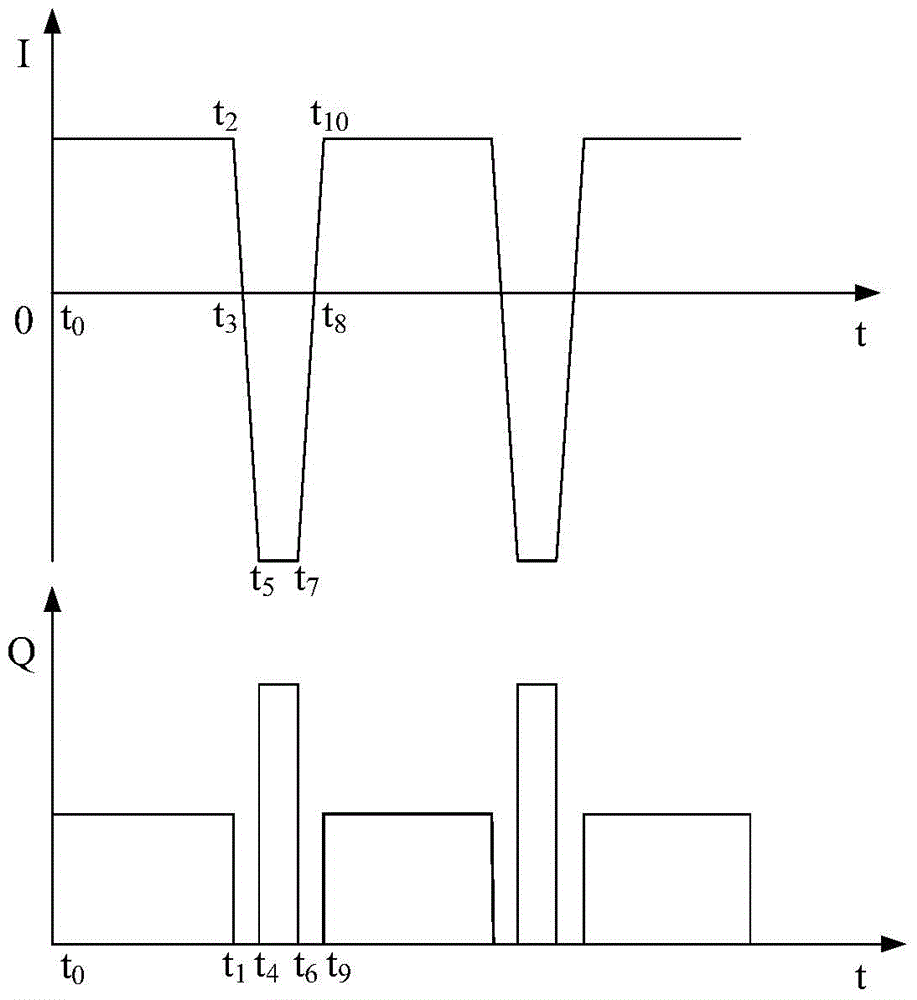

[0034] Step 4: Select the time node in a single cycle of the variable polarity current waveform to set the key time point t in the airflow waveform controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com